What you'll learn:

- Trends driving the design of more efficient components and systems.

- The benefits of employing efficient designs.

- Examples of how developers are improving the efficiency of various technologies.

Efficiency is becoming a more important feature for fluid power and other technologies utilized in various machinery applications. A greater emphasis on sustainability in recent years as well as a desire to improve machine productivity and reduce operational costs are all driving use of efficient systems and components.

The term efficiency can mean many different things. Jesse Dupuis, Director – Powertrain Product Management, Motion Control Solutions at Regal Rexnord, said lowering energy consumption is one of the more traditional forms of efficiency. But efficiency can also be looked at from a system perspective as well as logistics and supply chains, he said.

“When I think about efficiency, I'm also thinking about reliability,” said Jerry Collier, Vice President, Americas, John Crane — a developer of mechanical seals, couplings, filtration and diagnostic technologies. “If something is running more, then [it is] going to be reliable.”

Reliability means less downtime and maintenance, both of which can be costly and impede the operational efficiency of a business.

With the increased focus many machine owners in the mobile and industrial sectors are placing on efficiency, the development of more efficient hydraulic, pneumatic, electromechanical and other technologies is rising.

How Technology Developers are Achieving More Efficient Designs

As Dupuis explained, improving the efficiency of a component or system is commonly associated with reducing its energy consumption and is an area in which many manufacturers are focusing their technological development efforts.

This is how Danfoss Power Solutions thinks of efficiency when developing its hydraulic and other components, noted Dr. Andreas Schumacher, Senior Director, Head of Sustainability and Product Compliance, during a webinar with Power & Motion. “We are really focusing on the losses, which, from a technical aspect, would be described as power in, minus power out,” he said. “And what is left over is the efficiencies, and you can put that into the input power.”

Lucas Knapp, Vice President of Product & Marketing at HARTING, who also participated in the webinar, said his company thinks of efficiency in the same manner. “From a system or a component standpoint, we also define efficiency as power in through a system and power out,” he said. “How much power are you getting out of the system that you are using to drive your system, and how much loss is there across the spectrum?

“For example, we're in the electric connectivity space, and so we're trying to get power from one wire to another wire most efficiently, and with all of the transfer of that from one to the next, where we want to have the least amount of resistance through our system,” he explained.

Knapp said the materials used to transmit electricity are the most critical aspect of HARTING’s connector designs. “We spend a lot of energy and research on the right material selection and manufacturing processes to have that be the most effective in its application,” he said.

By choosing the right material for a given application, not only are performance requirements met but also opportunities for improved efficiency. For example, a contact the company developed for a high-power application enabled a 35% reduction in resistance to be achieved due to the effort HARTING put into selecting the right materials for energy transfer.

“The amount of power you’re getting out of this connected system is significantly more efficient,” said Knapp. “This provided real dollar savings and helped our customer meet real goals they were looking to achieve.”

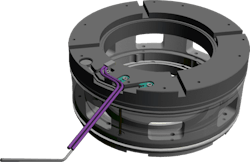

Collier said John Crane’s dry gas seal technology has been a big contributor to helping customers meet their energy efficiency targets. Besides preventing leaks, the seal features a non-contacting design which he said lowers heat generation — a common culprit of efficiency losses.

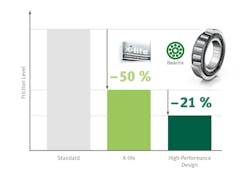

At bauma 2025 — a large international construction equipment trade show — Schaeffler was among the many companies showing how efficiency gains are being achieved on a component level with its friction optimized bearings, known as X-life, which have lower friction than standard products.

View our media gallery to learn about other technologies shown at bauma 2025.

Less friction leads to reduced energy needs from a machine’s power source to create movement, explained Simon Wienroder, Business Development, Off-Road at Schaeffler. He offered the example of replacing standard bearings in hydraulic pumps and motors in a wheel loader with the company’s X-life bearings which enabled the company to reduce the energy demand of the machine from 140 to 131 kW for an OEM customer.

Wienroder said the company is seeing more requests for such technology as some equipment manufacturers look to enhance the efficiency of their machine designs to reduce total cost of ownership for end-use customers.

By reducing energy demand, less fuel or battery power — depending on the machine type — is required and thus the amount of money spent powering a machine can also be reduced. Minimizing friction can also help to reduce wear and tear on systems, reducing maintenance time and costs as well.

A Systems-Level Approach is Key to Achieving Efficiency Gains

While there are many benefits associated with the use of efficient components, taking an entire system design into account can provide opportunities for larger efficiency gains.

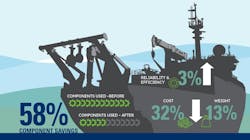

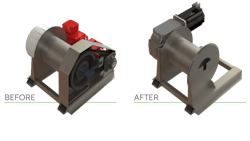

Dupuis gave an example of a winch Regal Rexnord worked on for a marine vessel application. The customer frequently had to maintain its original winch, impeding productivity.

By redesigning the winch so it had fewer components, Regal Rexnord was able to improve its efficiency. “We ended up with a reduction in the components in the system that inherently increased the efficiency of it from an operational standpoint,” said Dupuis. “That lowered the amount of fuel that they needed to consume to operate the winch…and there were fewer components that required routine maintenance.”

When looking to improve the efficiency of a system, he said it is important to ask questions and not feel constrained by using what already exists. There are a lot of opportunities to optimize efficiency, performance and other design factors by questioning what is possible.

Watch our interviews with Dupuis to learn about the different ways efficiency can be defined and an example of how Regal Regal Rexnord helped a customer achieve efficiency improvements by rethinking its system design:

How Efficient Components and Systems Can Reduce Operational Costs

Efficiency Gains Can Be Achieved by Questioning the Status Quo

As Schumacher explained during the Power & Motion webinar, many of Danfoss’ components have already been developed over the years to provide a high level of efficiency, but there are still opportunities to achieve further improvements by taking a system-level approach.

“If you want to really achieve [a high level of efficiency], then the system is the lever,” he said because there are not enough gains left to make on an individual component basis. For example, he said the company’s H1 Series hydraulic motor offers 95% peak efficiency which does not leave much room for further improvements.

Whereas by looking at an entire system and the strategy used to operate it, there is potential to achieve further efficiency improvements.

“We've had time to really understand the specific component that is causing resistance or power loss, and we've had many cycles of improving that over time,” said Knapp. “What we're finding now is a lot of people are looking at the system level design” because of the optimization that has taken place over the years on an individual component basis.

As part of this system-level approach, he said the ability to monitor technologies throughout their lifecycle is bringing longer term efficiency potential. “The idea of collecting data across the system” through the integration of sensors and the Internet of Things (IoT) enables users to see how systems and components are performing.

This data can help machine owners better understand when they may be drawing more power to do the same work and thus corrective action might be required such as adding more lubrication or performing maintenance on a component.

“The lower hanging fruit is in the system level design, the monitoring and the ability to get the data to help us be more efficient as we're operating,” said Knapp.

Collier agreed that monitoring capabilities can play an important part in the efficiency discussion when it comes to improving reliability and uptime. As such, the company developed a digital platform called John Crane Sense which he said provides real-time insight on mechanical seal behavior.

Sensors tracking key indicators such as vibration, acoustic emissions, liquid detection, speed, and temperature enable remote monitoring so machine owners can better determine if there are performance issues and address them before they create a downtime event.

“That improves the system performance, the seal performance, and it also helps [customers] avoid any unplanned outages,” said Collier.

Efficiency to Remain an Important Design Factor

Most agree that efficiency will remain an important factor in component, system and machine design going forward.

Although sustainability plays a part in the desire to use efficient technologies as they require less fuel and produce fewer emissions, for most it is about the return on investment (ROI). Industrial and mobile machinery is used for doing work and therefore needs to do that work in a reliable and cost-effective manner which efficient technologies can help them achieve.

How a business decides to improve efficiency varies from one customer and industry to another. Collier explained that some customers in the pulp and paper industry are focused on reducing energy consumption while others care more about uptime. “And in oil and gas and petrochemical they continue to find ways to reduce their operating costs,” he said. “Uptime, reliability and energy efficiency are key items that really impact their bottom line.”

Schumacher said the speed at which customers are embracing use of efficient technologies varies, but in general Danfoss is seeing it in most of the markets it serves because of the sustainability and ROI benefits that can be achieved.

In general, no matter what the customer market or reason is, he sees the trend for increasing efficiency continuing in the coming years.

View the below content for more information about efficient technologies and how to achieve efficiency in component and system designs.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech