How Efficient Components and Systems Can Reduce Operational Costs

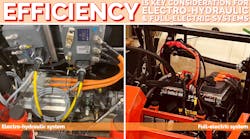

Efficiency is becoming an increasingly important aspect for many industries, including those served by fluid power and other power transmission technologies, because of the various benefits that can be achieved.

Jesse Dupuis, Director – Powertrain Product Management, Motion Control Solutions at Regal Rexnord, said you can think about efficiency in many different ways. Reducing the energy consumption of a component such as an electric motor is one form of efficiency.

“You also have efficiency in terms of a system,” he said. A power transmission system may include several components and “each one lowers the overall efficiency from the input power to whatever you’re trying to transmit to. That obviously adds cost to the system and maintenance.”

As such, Dupuis said Regal Rexnord is getting requests from customers to help them minimize the number of components which go into a power transmission system to reduce some of those inefficiencies.

In addition, the company is seeing increased requests for efficiency in terms of logistics and supply chain. “We've had a lot of companies tell us that they like the fact that we have continued to expand our portfolio…because then they can come to us with things like consolidated shipping, where they're not having to source from seven different companies,” he said. “They're not having to logistically manage the deliveries of all these seven companies or [multiple] purchasing orders, and there's efficiencies to be gained there.

“There's a lot of different forms of efficiency that we're getting requests for, and they kind of all come down to cost and trying to make things as cost effective as possible,” he said. “That cost goes beyond the initial capital investment you would make on parts and is more about total cost of ownership.”

In this interview with Power & Motion, Dupuis offers insights into the various forms of efficiency and benefits it can offer as well as technological developments enabling efficiency gains.

Learn more about achieving effiency by viewing the below content.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech