Understanding When to Switch from Pneumatic to Electric Actuators

Manufacturing and logistics operations have traditionally relied on pneumatic technology to power most automation solutions. Although electric actuators have been explored as potential replacements for many years, higher costs have typically limited their adoption to all but the largest players or specialized applications.

Today, however, economies of scale are beginning to make electric options more affordable and attractive. Viewed from a total cost of ownership (TCO) perspective, a case can often be made that electric systems are at least as cost-effective as pneumatics, and possibly even better. This argument is further supported by the unique capabilities electric actuators can offer.

Does this mean the time has finally come for warehouse and manufacturing operations to transition to electric systems? Is one design approach better than the other? This article will explore these questions and the various factors to consider when determining if it is time to make the switch from pneumatic to electric actuators.

Consider the Entire System Architecture When Choosing Between Pneumatic and Electric Actuation

Apples-to-apples comparisons are tricky when comparing pneumatic cylinders to electric actuators. It’s not enough to focus on the most obvious moving parts; the full system architecture of each technology must be considered.

At the component level, a pneumatic cylinder appears to be a lot cheaper and simpler. It’s basically a barrel, rod and piston, with a pair of O-rings and a cap at each end. Depending on the manufacturer, there might be other components to cushion the piston impact or improve performance, but the essentials are simple and easy to understand. It’s a purely mechanical system: all you need is a puff of air strong enough to make the piston move at the desired force.

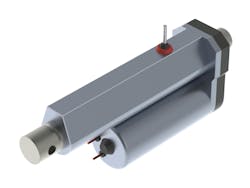

Electric actuators are more complicated and thus more expensive to produce. In their simplest form, a motor drives a ball screw, lead screw or belt to move an enclosed cylinder or external carriage. There will also be a few gears to manage torque, a connector for communication, and wiring for power.

However, this only provides part of the picture. To make those “cheap” pneumatic cylinders work requires fittings, miles of air lines, valves to actuate the air pressure back and forth, regulators to adjust the pressure, flow controls, and ultimately an air compressor — typically the most expensive and inefficient energy source in any plant or warehouse.

With all of the components required for a pneumatic system, there are a lot of places where things can go wrong:

- Dust will inevitably find its way into the system, which can make the entire plant or warehouse dirty while also creating health hazards for workers.

- Air lines and fittings leak, but it can be difficult to find the part that’s failed. Leak detection systems can run $50,000 or more, and many operations consider them worth the cost because wasted downtime can be even more expensive.

- Valves wear out and break down over time, compressors overheat or generate inadequate pressure when their filters get clogged, pressure switches malfunction, and so on.

- According to the U.S. Department of Energy, compressors are notoriously inefficient, typically losing 85-90% of their energy as waste heat and costing thousands of dollars to operate. For some facilities, compressed air generation may account for 30% or more of the electricity consumed.

- Many moving parts in pneumatic systems require oil for lubrication, which makes them messier and increases maintenance requirements.

Electric actuators, by contrast, arrive preassembled and don’t require much infrastructure. You simply plug them into a power source and connect them to your communication system. That’s it. Thus, when you look at an electric system as a whole, it actually has fewer moving parts and potential points of failure than a comparable pneumatic system.

With an electrical efficiency of 75-80% and low-voltage controllers, electric actuators require considerably less energy to operate. Unlike pneumatic cylinders, which require a constant supply of air to hold their position, electric actuators don’t necessarily need power to stay in place. They’re sealed against dust and lubricated for life, reducing maintenance and making the entire system cleaner.

View the content below to learn more about the use cases for pneumatic and electric actuation technologies as well as the benefits hybrid systems can offer.

Power vs. Precision: Which is Required for Your Application?

The type of performance you need will often be a major factor when deciding between pneumatic and electric systems.

If your application requires nothing more than brute force, it’s hard to beat the raw power and speed of a pneumatic cylinder. Need a harder wallop? Just install a bigger cylinder.

The trade-off is inconsistency. Even a small variation in air pressure can alter the amount of force a given cylinder delivers. What’s more, the only way to stop the piston at a particular stroke length is to provide a physical stop for it to slam into. Over time, that incessant pounding will wear the stop down, incrementally increasing the distance the piston travels. Multiply those impacts by tens or even hundreds of cylinders and you’re also talking about a lot of noise.

Although they may not be able to compete at the highest force levels, electric actuators still deliver sufficient speed and power for most applications. They can be programmed to stop at any point along their length of travel, making them much more precise and potentially more durable. If you need repeatable positioning — or even variable positioning — electric actuators are the only game in town.

Electric actuators offer greater versatility and future proofing because they can be reprogrammed if your automation specifications change. They’re significantly quieter since they don’t require a physical stop to control their stroke length; their machine noise level is comparable to an average human conversation. There’s also less correlation between the size of the actuator and the force it delivers, so in some cases, an electric actuator may be smaller than a comparable pneumatic cylinder.

Read the below articles to learn more about some of the applications which benefit from the use of pneumatic systems.

Take System Setup for Pneumatic Cylinders and Electric Actuators into Account

Another factor to consider when determining whether to use pneumatic or electric actuation is system setup.

Installing a pneumatic cylinder requires a mechanical technician until you get to the point where you’re wiring its sensor up to a programmable logic controller (PLC). From that point on, you’ll need a PLC programmer. Two different skill sets are involved.

With electric actuators, a programmer can handle the entire process. He or she simply needs to hook up a laptop and teach the actuator a few specifications. The leap for a PLC programmer to learn actuator programming is very minimal. While it’s certainly possible for a mechanical technician to learn either of these programming skills, there’s a bigger gap between the two disciplines.

The appeal of electric actuators is also growing as younger workers gradually replace an aging generation of maintenance technicians. Kids who grew up playing video games aren’t as intimidated by electronic technology and are often eager to learn something new. They’re also less inclined to work with dirty air cylinders.

That said, experience shows that techs prefer simple, intuitive and robust interfaces for setting up communication. Smart manufacturers recognize that this can be a clear point of differentiation between different electric options.

Feedback Capabilities of Electric Actuators a Desirable Benefit for Some Applications

A unique feature of electric actuators is their ability to provide feedback to your control system. This empowers a variety of benefits that aren’t possible with pneumatics, including:

- Condition monitoring and predictive analytics, which can minimize unplanned downtime by detecting potential problems before they impact productivity or cause equipment failure.

- Dynamic motion control and health awareness to ensure consistent stroke positioning in critical applications — compensating for system wear and extending actuator life.

- Variable positioning and resistance sensing, which allows actuators to perform multiple tasks or handle objects of varying sizes without reprogramming.

- Smart communication and data reporting, enabling performance optimization.

Evaluating Total Infrastructure Costs is the Ultimate Determining Factor

Ultimately, the trade-off between cost and performance continues to be the primary consideration when either pneumatic or electric actuators can handle a given facility’s automation requirements.

Download our eBook, "The Shift from Fluid Power to Electromechanical Technologies" for more insights on why some applications are transitioning away from fluid power solutions and tips on how to choose between hydraulic, pneumatic and electric actuation options.

Although pneumatics continues to offer lower up-front costs, the gap is narrowing. In many cases, electric actuators may provide a lower TCO by simplifying your infrastructure, reducing maintenance, and extending equipment life.

Whichever you choose, it’s essential to evaluate the total infrastructural costs, as well as long-term factors like scalability and component durability.

It’s also worth weighing less tangible considerations like labor satisfaction. In industries known for scarce labor and high turnover, the quieter and cleaner environments that electric actuators enable can be a recruiting advantage. An investment in electric solutions could be money well spent if it helps you retain and attract good people.

This article was written and contributed by Doug Vorhees, Engineering Manager, Warehouse Automation at Johnson Electric.

About the Author

Doug Vorhees

Engineering Manager, Warehouse Automation, Johnson Electric

Doug Vorhees is Engineering Manager, Warehouse Automation at Johnson Electric, a developer of motion products, control systems and flexible interconnects. Vorhees has been with the company since 2022 and holds a Bachelor of Science in Manufacturing Technology.