How Electrification is Reshaping Industrial Automation

The desire for energy efficiency and use of digital solutions is driving the electrification of industrial automation applications such as used for packaging machinery and machine tools.

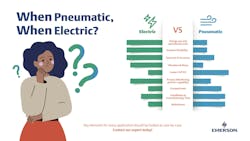

While this is leading to increased adoption of electrified motion control solutions, Nick Buccheri, President Americas Discrete Automation at Emerson, explains that this does not necessarily mean one technology is being replaced by another. Instead, it is about choosing the best motion solution for a given application. This can mean electric, pneumatic or a hybrid of these technologies is chosen.

In this interview with Power & Motion, Buccheri discusses what industrial electrification entails, the technologies being employed as well as how he sees this trend continuing to evolve.

*Editor's note: Questions and responses have been edited for clarity.

Power & Motion: How is electrification taking place in industrial applications (i.e. stationary manufacturing/production machinery)?

Nick Buccheri: Industrial electrification is evolving rapidly, but it’s not about replacing one technology with another — it’s about choosing the best motion solution for each application. At Emerson, we see customers optimizing their automation systems by integrating electric, pneumatic, and hybrid motion control solutions to achieve higher efficiency, flexibility, and sustainability.

“Electrification is reshaping industrial automation, but success lies in choosing the right mix of electric, pneumatic, and digital technologies.”

As industries focus on energy efficiency and digital transformation, we are seeing greater adoption of electrified motion control in areas where precise speed control, flexible positioning, and real-time data insights are critical. At the same time, pneumatics remains a proven, cost-effective choice for many high-speed and high-force applications. Emerson supports both electrification and pneumatic advancements, ensuring that manufacturers have the right mix of technologies to meet their operational goals.

Power & Motion: How does electrification of industrial machinery differ, if at all, from mobile machinery and vehicles?

Nick Buccheri: While industrial automation benefits from a stable power infrastructure, mobile machinery must rely on battery storage and regenerative energy strategies. In stationary applications, electrification enables real-time performance optimization, precise speed control, and seamless integration with digital automation systems. In contrast, mobile systems prioritize energy efficiency and power management, balancing electrification with weight and battery constraints.

Power & Motion: Are there specific types of industrial machinery where you see electrification taking place more than others?

Nick Buccheri: Electrification is growing in applications that benefit from real-time data, precise control, and energy efficiency, such as:

- Packaging & Material Handling — Conveyor systems, robotic arms, and automated warehouses are increasingly using electrified motion for faster speeds and more flexible product handling.

- Machine Tools & Precision Automation — CNC machines and high-precision manufacturing systems are adopting servo-driven motion control for repeatability and accuracy.

- Fluid Control & Process Automation — Some valve actuation and motion tasks are shifting toward electrified actuators, especially in digitally connected smart factories.

However, pneumatic solutions continue to play a vital role, particularly in high-speed, high-force applications, where they remain cost-effective, durable, and reliable. Emerson provides both technologies so that manufacturers can tailor their automation strategies based on application needs.

Power & Motion: What is driving electrification in the industrial machinery sector?

Nick Buccheri: Electrification is part of a broader shift toward more energy-efficient, connected, and sustainable automation, driven by:

- Sustainability & Efficiency Goals — Companies are focusing on reducing emissions and optimizing energy use. Electrified solutions provide higher energy efficiency in certain applications, while advanced pneumatics continue to offer low-energy, high-performance motion solutions.

- Industry 4.0 & Digitalization — Modern factories require real-time data, predictive maintenance, and Industrial Internet of Things (IIoT) driven automation. Emerson’s Floor to Cloud™ strategy ensures that both electric and pneumatic solutions integrate seamlessly with digital control systems.

- Total Cost of Ownership (TCO) Considerations — In some applications, electrification reduces maintenance and energy costs, while in others, pneumatics remains the most cost-effective solution. Emerson helps customers make data-driven technology choices.

- Flexibility & Productivity Demands — Modern automation systems require fast changeovers and adaptive motion control. Electrification provides multi-position flexibility, while pneumatics delivers fast cycle times and high-force applications.

Rather than a one-size-fits-all approach, Emerson enables manufacturers to evaluate both pneumatic and electric motion control based on their specific performance, cost, and efficiency needs.

Power & Motion: What are some of the technologies involved with the electrification of industrial machines?

Nick Buccheri: Electrification is expanding the automation toolkit, but it is not replacing traditional technologies — instead, it is creating new opportunities for hybrid automation. Key enabling technologies include:

- Servo Drives & Motors — Used in high-speed automation and motion control, providing precise positioning and adaptive speed control.

- Electric Actuators & Smart Valve Control — Offering energy-efficient alternatives to some pneumatic systems, while still working alongside advanced pneumatic automation.

- IIoT & Edge Computing — Both electrified and pneumatic systems are now integrating real-time sensors, diagnostics, and predictive analytics.

- Smart Energy Management — Emerson’s Energy Manager and Compressed Air Manager help manufacturers track and optimize power and air consumption.

- Hybrid Motion Control — Many applications benefit from a combination of electric and pneumatic motion. Emerson provides both, ensuring flexible automation solutions.

The future isn’t just electrification — it’s smart, connected automation that integrates the best of electric and pneumatic motion control to maximize performance.

Power & Motion: What are some of the challenges and opportunities associated with electrification of industrial machinery?

Nick Buccheri: Some of the challenges associated with electrification include:

- Upfront Investment — While electrification offers long-term efficiency, initial costs must be carefully evaluated. Emerson helps customers balance TCO with operational benefits.

- Application-Specific Needs — Some applications benefit more from pneumatics, while others favor electrification. Emerson provides hybrid solutions to ensure the best technology fit.

- Infrastructure Considerations — Increasing electrification may impact power distribution, just as pneumatic solutions require compressed air optimization.

Whereas the opportunities are:

- Higher Efficiency & Productivity — Electrification optimizes precision and flexibility, while pneumatics provides fast, repeatable motion. Emerson helps customers choose the right mix.

- Sustainability & ESG Compliance — Emerson enables customers to reduce emissions, optimize air usage, and improve overall energy efficiency.

- Predictive Maintenance & Smart Factories — Both electric and pneumatic motion solutions are becoming smarter and more connected, allowing for real-time diagnostics and data-driven decision-making.

At Emerson, we work closely with manufacturers to implement intelligent automation strategies that balance efficiency, cost, and sustainability.

Power & Motion: How has Emerson seen electrification in industrial applications evolve in recent years, and what further advancements in this area does the company anticipate in the coming 3-5 years?

Nick Buccheri: Electrification is expanding rapidly, but rather than replacing traditional automation, it is creating new hybrid opportunities. Emerson has seen:

- Greater Integration of Electric & Pneumatic Motion Control — Today’s factories require flexible automation strategies that balance energy efficiency and performance.

- The Rise of Smart Energy Management — Emerson’s Floor to Cloud™ automation approach ensures that both electrified and pneumatic systems contribute to optimized energy use.

- More Intelligent Motion Control — Electrification and pneumatics are becoming smarter, integrating with IIoT and AI-driven automation.

Our future outlook entails:

- More Hybrid Automation Solutions — The future is not just electric, it’s intelligent automation that combines electric, pneumatic, and digital systems.

- AI-Driven Performance Optimization — Both electrified and pneumatic motion solutions will become more adaptive and self-optimizing.

- Seamless Floor to Cloud™ Integration — Emerson will continue driving connected, data-driven automation that enhances efficiency across all motion technologies.

At Emerson, we don’t see electrification as a replacement, we see it as part of an evolving automation landscape where manufacturers use the best technologies for their specific needs.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech