How Hybrid Actuators Can Benefit Modern Press Applications

Key Highlights

- Hybrid linear actuators have emerged as a suitable option to meet requirements for improved efficiency, control and other performance attributes in press machines.

- Hybrid actuators combine the best elements of electromechanical actuation with those of traditional hydraulics, enabling them to achieve the many performance goals of modern machinery.

- A range of industrial and mobile applications are making use of hybrid actuators because of the benefits they provide such as a compact and leak-free design, ability to tolerate shock loads and incorporation of Industry 4.0 technologies.

Across various industrial and mobile applications, the push for electrification is accelerating. Engineers are being asked to replace inefficient hydraulic systems with electric actuation solutions that offer improved energy efficiency and sustainability, precise control of force and position, ease of integration with various control platforms, and require minimal maintenance.

Download our e-Book "The Shift from Fluid Power to Electromechanical Technologies" to learn more about some of the applications switching to electromechanical solutions as well as tips on selecting the right technology for your application.

Electromechanical screw-type actuators are well-suited for many applications, however they are limited in applications that experience shock loads, have demanding duty cycles, and place wear on mechanical components (screws, bearings, belts).

At the same time, traditional hydraulic actuation systems introduce their own set of inadequacies, including energy inefficiency because they are constantly running (even when work is not being done), maintenance and safety concerns due to hydraulic fluid leaks, as well as taking up a large footprint.

In pressing and other machinery applications, hybrid actuation has emerged as a viable option in response to this increasing demand for electrification and sustainability by combining the best elements of electromechanical actuators and traditional hydraulics while eliminating their drawbacks.

The Benefits of Hybrid Actuation Technology

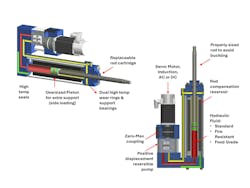

Hybrid linear actuators are self-contained actuation systems that integrate a motor and pump directly onto a hydraulic cylinder. Unlike traditional hydraulics, there’s no separate hydraulic power unit, long hoses, or leak points. They only use power when commanded to move the desired load.

There are several benefits offered by hybrid linear actuators –

- Energy efficiency: power-on-demand reduces wasted energy.

- Leak-free, low maintenance: a sealed, leak-free design eliminates the need for bulky hydraulic power units, external reservoirs, filters, or hoses.

- Shock and side-load tolerant: handles the impact of sudden forces with superior durability.

- Scalability and flexibility: force ranges from 100- 150,000 lbs. with precise position and force control.

- Future Ready for Industry 4.0: incorporates feedback sensors, diagnostics, and smart control options for real-time monitoring and predictive maintenance.

- Cost effective: eliminates regular fluid and filter replacements and used fluid disposal.

Why Hybrid Actuators are a Natural Fit for Press Applications

Press applications can be found across a multitude of manufacturing processes, from assembly and clamping to punching, forming, and extruding. These applications share commonalities when it comes to actuation requirements. Engineers must optimize force, precision, speed, repeatability, and durability while maintaining efficiency and cycle-to-cycle consistency.

In press operations, multiple motion profiles are involved. The actuator needs to have a controlled approach then apply force. In some instances, actuators need to limit force so as not to damage parts or tooling, while at other times they need to hold or apply force. In order to produce consistent results, being able to switch seamlessly between position and force control is essential.

For engineers evaluating actuation technologies for use in press applications, visit Kyntronics' website to download a technical resource from the company that explores common press requirements, industry trends, and actuation technology tradeoffs in greater detail.

Inherent with pressing applications, sudden impacts, known as shock loads, are likely to occur. These momentary spikes can cause significant mechanical stress on an actuator. Actuators used in these applications require the ability to handle those conditions without failure or loss of accuracy, requiring costly maintenance.

Hybrid linear actuators address these requirements, integrating the power of hydraulics with the precision of electric control. The hybrid design enables precise, repeatable position and force while handling shock loads often seen in press operations. Due to the power-on-demand advantage hybrid actuators have, they support energy efficiency and sustainability goals that engineers and their organizations face.

Hybrid Actuators Provide the Control Capabilities Engineers Require

In pressing and other industrial applications with similar performance requirements, engineers must be able to control motion profiles such as position, force, dwell, acceleration, deceleration, and speed.

Programmable hybrid linear actuators, often with built-in Fieldbus communication, support these requirements with closed-loop control.

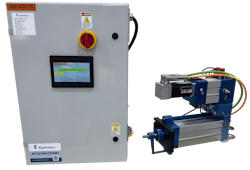

In these applications, closed-loop control plays a critical role, making it easy for the programmable logic controller (PLC) to send basic commands. This enables press systems to operate in position control, force control, or position with force limit mode. Engineers are also able to switch seamlessly between the modes per their application requirements.

Press systems benefit from synchronization of multiple actuators for coordinated motion. Additional control functions include locking and hold logic for safety and stability, auto-tuning for consistent performance across varying loads, and optional Human Machine Interface (HMI) to provide full visibility and control via touchscreen interface. By utilizing the optional HMI, engineers and plant personnel can easily access diagnostics, sequencing, recipe management, quality checks, and data logging.

These stand-alone programmable control capabilities allow hybrid linear actuators to meet the engineering requirements of press and similar applications all while supporting Industry 4.0 trends and reducing system complexity.

Extending Hybrid Actuation Across Industrial and Mobile Applications

Many of the performance characteristics found in press applications are equally relevant in other applications as well, including testing, material handling, valve actuation, and mobile equipment, to name a few.

Precision, reliability, and efficiency are essential to ensure accurate results and repeatable performance in many of these applications. Hybrid linear actuators offer the programmability necessary to meet these and other application requirements.

In addition, the totally sealed design of hybrid actuators eliminates the leak points inherent with hydraulics, minimizing maintenance, downtime, and environmental impact while improving personnel safety and insurance risk.

Hybrid actuators are also gaining momentum in mobile applications moving toward electrification. Compact packaging, high force, and energy-efficiency requirements play a role in their selection for these types of applications.

Hybrid actuation systems deliver hydraulic-level force with the precision of pure electric actuators, operating on a power-on-demand basis. These features make hybrid actuators ideal for mobile equipment, especially where energy efficiency and robust performance under dynamic loads are required.

Best Practices for Selection and Sizing of Hybrid Actuators

When it comes to sizing hybrid actuation technology for an application, the process is simple for engineers. Few details are needed to determine suitability for the application including force, speed, and stroke requirements. There is no need to be concerned about leads, screw pitches, belt sizes, gearing, or L10 life (bearing fatigue) calculations.

Hybrid linear actuators seamlessly replace existing traditional technologies in the field. In the case of the replacement of hydraulic cylinders, operating pressure, cylinder size, and cycle speed are needed to determine a hybrid alternative versus electromechanical actuators, which can often be cross-referenced by part number to ascertain a hybrid solution.

Following are a few considerations to keep in mind when selecting actuators for industrial and mobile applications:

- Avoid oversizing – this increases cost, factory footprint, and energy use.

- Design for uptime – systems that require frequent maintenance and lubrication increase cost and downtime.

- Think beyond upfront cost – maintenance, downtime, and energy use are significant over operating life.

- Prioritize safety & ergonomics – system safety matters just as much as output.

- Match performance to application needs – precision and consistency are vital, so tailor actuator selection to process requirements.

- Future-ready flexibility – programmable and Internet of Things (IoT)-enabled actuation technologies deliver precise control which improves part quality, supports pass/fail checks, data collection, and predictive maintenance, and extends tooling life.

Hybrid Actuation Plays Important Role in the Next Phase of Electrification

Hybrid actuators fill a capability gap between legacy hydraulic systems and electromechanical actuators. They provide engineers with another technology option to consider as the push towards electrification, sustainability, and efficiency continues across industrial and mobile applications.

Simply relying on traditional hydraulics or electromechanical screw-type actuators make it hard to meet those goals. Hybrid actuation, by blending the best features of those two technologies, provides engineers with flexibility in demanding applications. This makes them especially useful when accuracy, precision, and energy efficiency matter most.

This article was written and contributed by Carl Richter, VP & General Manager, Kyntronics.

About the Author

Carl Richter

Vice President and General Manager, Kyntronics

Carl Richter is the Vice President and General Manager at Kyntronics, a Cleveland-area (Solon, OH) manufacturing company specializing in advanced hybrid actuation solutions. With a background spanning both technical and business leadership, he drives innovation focused on energy efficiency, sustainability, and system-level performance. Richter is a published industry thought leader and frequent webinar contributor, with work featured in multiple industry publications on topics including electro-hydraulic efficiency and the transition toward electrified actuation systems.

Leaders relevant to this article: