How Integrated Linear Actuators Simplify Design and Elevate Performance

What you’ll learn:

- The difference between traditional and integrated electric actuators.

- Key factors aiding uptake of integrated electric linear actuators.

- How integrated electric actuators are being deployed in real-world applications.

Meeting today's demands for faster, more efficient and simpler machine designs often hinges on selecting the right components. Linear actuators play a critical role in powering numerous industrial machines, and are key to meeting these challenging requirements.

When specifying linear actuators, engineers face the choice of either traditional or integrated electric linear actuator designs. Traditional actuators consist of a screw assembly driven by an externally mounted servo motor, while integrated actuators contain a servo motor within the same module.

Although traditional actuators offer advantages like motor option flexibility and high stroke lengths, many applications would benefit from an integrated actuator’s compact form, lighter weight, higher rigidity and greater protection.

This article examines why integrated linear actuators are increasingly the preferred choice in industrial applications — including robotics and automated systems — offering streamlined design, improved performance and enhanced reliability compared to traditional actuator setups.

Integrated Versus Traditional Actuator Designs

Integrated servo motor actuators combine the motor and actuator in a single unit, creating a more compact, streamlined and space-efficient configuration. This design places the center of gravity along the actuator’s center axis, which is beneficial for applications requiring precise and efficient movement, such as end-of-arm tooling (EOAT).

Traditional actuators, on the other hand, consist of separate components such as the actuator, motor, drive and controls. The motor is typically mounted externally, either inline or parallel to the actuator. While this configuration is more flexible in terms of motor selection, it creates a larger footprint and more complex assembly, as additional components and joints are required.

Benefits of Integrated Actuators

One of the primary reasons machine builders are gravitating towards integrated servo motor actuators is the simplified design and integration process. An integrated actuator’s screw assembly rigidly connects to an internal hollow-core servo motor. Both the screw and nut assemblies travel within the rotor, and a set of angular contact ball bearings support the screw and rotor assemblies. Applying external anti-rotation methods to the thrust rod and nut assembly ensures linear motion. This design creates a more compact actuator with fewer components and better precision compared to traditional designs, leading to a number of benefits.

Easy integration and lower cost. One defining advantage of the integrated actuator design is that it removes the hassle of specifying and mounting a motor. Traditional actuators require a third-party motor, and these components usually share the same manufacturer as the servo drive. While this practice simplifies traditional actuator integration, integrated actuators completely eliminate motor integration time and cost. Accounting for additional components like feedback devices and cables further amplifies this simplicity.

Another advantage of integrated actuators is their cost compared to traditional actuators. While a single traditional actuator might be less costly, additional expenses in the purchase and installation of a servo motor make the overall price similar to or more than the cost of an integrated actuator.

Optimal size and weight. Integrated actuators are a good choice to meet size requirements because they are generally more compact compared to similar-performance traditional actuators, offering greater flexibility in machine designs.

Weight considerations are essential for applications where the actuator contributes to moving mass like in industrial robots. Because it includes the servo motor in the same package, an integrated actuator might weigh more than a standalone traditional actuator. However, depending on the motor, traditional actuator systems can be heavier and have an awkward center of gravity.

Thanks to a compact design, an integrated actuator’s center of mass is located along the center axis and closer to the mounting face. This feature allows integrated actuators to support more efficient movement.

Excellent protection. Traditional actuators tend to require more components, meaning more joints will require sealing. On the other hand, integrated actuators have less components and joints, offering greater ingress protection and making these components better suited for harsh environments with dust, debris and moisture.

The integrated actuator can also withstand shocks and vibrations. The further an actuator’s center of gravity is from its mounting surface, the greater the stress on the mounting fasteners. With a center of mass closer to the mounting surface than its traditional counterpart, an integrated actuator is less sensitive to shocks and vibrations.

High efficiency. With fewer components that transmit torque and rotate versus traditional actuators, integrated actuators have fewer sources of wear, misalignment and sideloading. This design reduces friction and ensures greater efficiency and reliability.

Greater acceleration and minimal backlash. To minimize the backlash that detracts from an actuator’s positioning accuracy and bi-directional repeatability, integrated actuators feature a rigid connection between the rotor and screw shaft. This design provides greater accuracy and repeatability than traditional designs, which use belts, pulleys, couplers or gearboxes to connect to the rotor — all of which introduce backlash.

Thanks to this design, the actuator has a much stiffer torque transmission system, increasing the system’s overall resonant frequency and delivering higher acceleration and responsiveness.

Increased safety. Both traditional and integrated actuators have holding brakes to arrest the rotor in case of power loss. This component is crucial in vertical applications where power loss can impact product or operator safety.

Unlike traditional actuators, the integrated design features a rigid connection between the brake and screw assembly. Without the belt or coupling system between the brake and screw assembly found in traditional designs, the integrated actuator eliminates potential failure points and ensures brake engagement.

Energy efficiency and sustainability. Integrated linear servo actuators increase energy efficiency by reducing friction and eliminating the intermediary components that cause energy losses in traditional systems. The rigid connection between the rotor and screw shaft ensures efficient torque transmission, reducing power consumption and improving system performance.

Furthermore, the compact and lightweight design of integrated actuators reduces the energy required to move the actuator itself, which is particularly beneficial in applications involving frequent starts and stops. For example, IMA Series actuators from Tolomatic Inc. (read more about these actuators in the sidebar below) are known for their high power density, enabling them to deliver up to 8,000 lbf while maintaining energy efficiency.

In addition to energy savings, integrated actuators support sustainability goals by reducing the need for lubricants and minimizing maintenance requirements. Their long operational life and reduced resource consumption align with the growing emphasis on sustainable manufacturing practices across various industries.

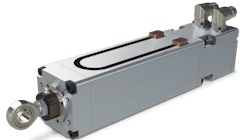

The IMA Series Integrated Linear Actuator

The Tolomatic IMA Series of integrated linear servo actuators offer high positional accuracy and excellent force repeatability. For long-lasting operation, the IMA is available with either ball or roller screw assemblies. A compact, lightweight construction enhances the IMA’s flexibility in machine designs. The actuator also meets heavy-duty application requirements by providing up to 8,000 lbf and featuring IP65 and IP67 protection rating options. Offering excellent compatibility, the IMA supports many third-party, industry-leading drive manufacturers.

IMA actuators are also available in stainless steel and food-grade models. The IMA-S consists of a stainless steel construction with an IP69K rating and can withstand harsh washdown conditions. The IMA food-grade model also offers washdown protection and features a food-grade white epoxy coating and food-grade lubrication. Stainless steel fasteners, rods and rod ends are also available.

These integrated actuators are ideal for a variety of applications like industrial automation, pressing tasks, end-of-arm tooling, food and beverage equipment, pneumatic or hydraulic replacement — and more.

Another series of integrated linear actuators, the ServoWeld CSWX, is ideal for spot welding applications in automotive plants.

A Look at Real-World Applications For Integrated Actuators

Integrated linear servo actuators offer a high degree of customization to meet the unique requirements of various industrial applications. Manufacturers can choose between ball screw and roller screw configurations, depending on the desired balance between cost, durability and performance.

Ball screws are suitable for high-speed, low-force applications, for example, while roller screws excel in high-force, heavy-duty scenarios.

Tolomatic’s IMA Series, for instance, supports a wide range of third-party servo drives, allowing seamless integration into existing automation systems. This flexibility enables machine builders to scale their designs without compromising performance or compatibility.

In addition, integrated actuators can be tailored with features like hygienic housings, advanced feedback systems and specialized mounting options to address industry-specific challenges. This adaptability makes them a versatile solution for diverse sectors, including automotive, aerospace, food and beverage and pharmaceuticals.

The following real-world examples demonstrate how use of integrated linear actuators helped machine builders elevate machine quality and performance.

Motion Simulator Manufacturing

Actuators achieve realistic motion simulation in the aerospace and defense industry. One simulator manufacturer used hydraulic actuators to simulate disturbances with vibrations featuring frequencies ranging from 30-50 Hz. Although this manufacturer achieved the aggressive motion necessary with the hydraulic system, the challenges of leaks, high maintenance and noise outweighed the system’s usefulness.

To enhance its simulator design, the hydraulics were replaced with Tolomatic’s integrated IMA44 servo actuator, which met performance specifications and operated without requiring an external cooling system that used water or oil. Because of the high-frequency motion requirements, the manufacturer couldn’t use a traditional rod style actuator. The IMA’s integrated design rigidly couples the integrated roller screw and servo motor into one component, making it ideal to handle the high-frequency motion required.

Before delivering the actuator, it was tested in Tolomatic’s engineering lab to ensure its performance met customer specifications, including temperature limits and lubrication intervals. Due to the IMA’s compact design, replacing the hydraulic cylinder of the previous system didn’t require any major mechanical design changes.

Now, the manufacturer has a high-performance, highly dynamic actuator that meets the high-frequency motion requirements without leaks and significantly less noise. This new integrated actuator system also features a longer life than traditional designs and requires minimal maintenance.

Automotive Welding

An automotive manufacturer used a rod-style servo-electric actuator to perform resistance spot welding. However, its machine had trouble sensing the sheet metal with the electrode while using motor feedback to detect when the electrode tip contacts the metal.

Tolomatic provided a CSWX ServoWeld Actuator, an integrated actuator that features the company’s skewed motor winding design. This compact, power-dense actuator was ideal for the EOAT application. The skewed motor windings allow the CSWX to deliver superior sensitivity, while the windings minimize torque ripple and improve sensing reliability when the electrode makes initial contact.

Because of the greater sensitivity, the CSWX provided improved, consistent weld quality as electrodes wear over time and superior performance compared to traditional servo motor actuators. These benefits also increased production throughput due to reduced downtime.

Pharmaceutical Production

A pharmaceutical manufacturer designing a new filling and packaging machine required an actuator to operate a gate for vial indexing. Because of the highly sterile environment, the actuator had to meet stringent hygienic requirements.

Tolomatic provided the manufacturer with an IMA-S actuator because of its suitability for hygienic environments. To ensure proper specification, the manufacturer downloaded 3D CAD files from the Tolomatic website and verified the fit and mounting in its assembly. The IMA-S actuator’s roller screw provides high accuracy and zero backlash.

Due to its enclosed, hygienic design and 316 stainless steel construction, the actuator could withstand the manufacturing environment’s wash-down chemicals.

Aseptic Plastic Injection Molding

A manufacturer of plastic injection molded parts used in pharmaceutical and medical industries needed to build equipment without hydraulics. While hydraulics offered the power density and force required, risk of hydraulic contamination prohibited their use in the aseptic manufacturing environment.

Tolomatic’s IMA linear servo actuator offered a clean electric solution. Meeting the space requirements, this actuator also provided the necessary forces and speeds for the equipment specifications. The actuator is also flexible enough to operate with the existing PLC (programmable logic controller) and motion control package.

By combining the motor and actuator into a single unit, integrated linear actuators address the needs of modern machine design — simplifying integration, enhancing performance and improving reliability. Engineers looking to build more compact, efficient and robust machines should seriously consider the advantages that these integrated solutions offer over traditional multi-component systems.

This article was written and contributed by John Fenske, Director of Marketing, Tolomatic Inc.

About the Author

John Fenske

Director of Marketing, Tolomatic Inc.

John Fenske is the Director of Marketing at Tolomatic Inc., a developer of linear motion solutions including pneumatic and electric actuators.

Leaders relevant to this article: