Why Electric Actuators are Replacing Hydraulics

Hydraulics can provide the force required of many industrial applications. However, advancements in electric actuator technology over the last 30 years have made them a viable alternative.

Also referred to as electromechanical actuators, these devices are able to provide improved precision, flexibility and reliability with a bore size equivalent to that of hydraulic cylinders. Today’s electric actuators are also capable of exerting up to 100,000 lbs. of force, enabling them to compete with many hydraulic technologies.

This is not to say that hydraulics will be completely replaced by electric actuators in industrial applications. The high force, compact size and rugged design offered by hydraulic cylinders as well as the fact they are simple to deploy continue to make them a good choice for many types of industrial machines.

But there are also many benefits offered by electric actuators which have led to their increased use in recent years.

Three Reasons to Choose Electric Over Hydraulic Actuators

According to Tolomatic — a developer of electric, pneumatic and other motion components — there are a variety of reasons its customers are choosing to use electric actuators over hydraulic cylinders, but three main factors are driving the shift to electric:

- reduced footprint and system complexity,

- fewer maintenance requirements, and

- motion control flexibility.

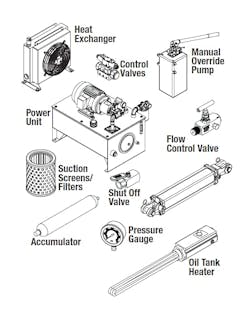

Design Simplicity

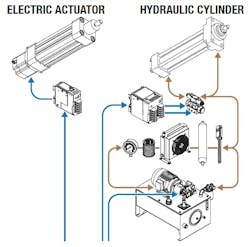

The design of electric actuators is not as complex as that of hydraulics, which is one of the reasons customers choose them over the latter. As Tolomatic explained to Power & Motion, there are very few components in an electric actuator compared to a hydraulic system. Hydraulics require valves, regulators, hoses, hydraulic power units (HPU) and more. And there is the potential for any of these components to leak or fail over the life of a machine, the company said.

If the hydraulic system leaks, the hydraulic oil can be time consuming to clean up and could cause potential environmental concerns. There is also the potential for safety issues if oil contaminates manufactured products.

All the components required by a hydraulic system necessitate a larger footprint in a manufacturing facility, as well, which can be difficult to accommodate if space is at a premium.

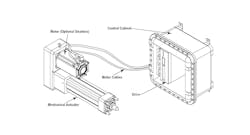

Electric actuators, on the other hand, do not use oil and therefore leakage issues are not a concern. In addition, they have a smaller overall footprint as the system consists of the actuator, a motor (often a servo or other device), cables, and a drive or amplifier which is typically housed in a control cabinet. There may also be an optional gearbox.

Per Tolomatic, an electric actuator does require more length than a hydraulic cylinder because of its integrated power screw and bearing system but it uses a servo drive which is a fraction of the size of the HPU utilized by hydraulic systems, helping to provide a smaller overall footprint.

The company said the growing use of planetary roller screws in electric actuators have helped them achieve higher life ratings and greater force capabilities in a much smaller package (versus ball screws). This enables electric actuators to fit into some applications previously dominated by hydraulics.

Reduced Maintenance

The lower maintenance requirements of electric actuators are helping drive their use over hydraulics as well. According to Tolomatic, electric actuation has very little to no maintenance over the life of a machine.

Use of planetary roller screws in electric actuators has enabled the longer life and low maintenance desired by many machine users, the company noted. In addition, the power elements (power screw and thrust bearings) of the actuator are usually greased for life. But in-field greasing methods can be used if needed.

The other component on an electric actuator which could wear is the rod seal. If failure occurs, though, the actuator can still operate as desired because it does not hold pressure like a hydraulic component would. And the seal can be replaced if damaged.

A hydraulic system typically requires routine maintenance to change the oil and filters in order to ensure continued performance. It may also be necessary to replace fittings, valves or other components over time.

Tolomatic noted there is also a growing lack of skilled maintenance people knowledgeable in hydraulics which is helping fuel the speed of adoption for electric actuation.

READ MORE: Increased Demand for Uptime and Reliability Driving Move to Electric Actuators

Improved Precision and Position Feedback

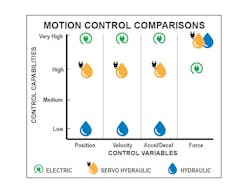

One of the top reasons electric linear actuators are chosen over hydraulic cylinders is the motion control capabilities they provide. The pairing of electric actuators with a servo drive and motor system allows users to know with certainty the actuator’s position at all times as well as its speed, accelerations, forces, and more. Whereas a hydraulic system would require a number of expensive instruments to be added to the system to get similar information.

These capabilities enable more accuracy and repeatability to be achieved with electric actuators which benefits a range of industrial applications, especially as they become more automated.

Additional motion control benefits offered by electric actuators outlined by Tolomatic include:

- thrust capabilities on par with hydraulics are possible,

- consistent monitoring of torque allows appropriate force control without maintenance or system adjustment,

- closed-loop control enables multiple positions to be achieved without the use of external sensors.

Hydraulic vs. Electric Actuators: Key Deciding Factors

Although there are many benefits to using electric actuators, there remain applications for which hydraulics are still a good fit.

Tolomatic said there is no doubt that hydraulic cylinders have the capability to provide great power density which means there are some machine installations where it is not currently feasible to utilize electric actuators. There are electric actuators available in the market capable of up to 50 tons of force, the company said, but forces above this point are less common for electric actuators due to the size of the screw/actuator and the availability and size of the servo motors. However, advances in technology may allow electromechanical actuation of higher force applications in the future.

Understanding the working force required of an application is a key determining factor when choosing between electric and hydraulic actuators.

The company said it always works with customers to determine the true working force of a hydraulic cylinder. The actual working force needs to be calculated by looking at the pressure drop of the hydraulic fluid in combination with the diameter of the actuator cylinder. The costs of electric actuators and motors can vary more significantly than hydraulic cylinders and is often the key in getting a cost-effective electric actuator solution, said Tolomatic.

An advantage offered by electric actuators is the fact that force can be generated instantaneously unlike a hydraulic cylinder which has to wait for pressure to build up to create the required force. Adjustments to the actuator’s performance can also be done automatically because its servo controller regulates the electrical current used to power the device which is available as needed.

Conversely, the HPU used with a hydraulic system must always keep pressure in the system which can be difficult to do and thus can have an impact on response time and the ability to adapt to any necessary performance changes.

The environment in which a motion system will be used is also important to take into account. Temperature fluctuations, for instance, can impact the performance of hydraulic oil and thus the overall system. Additional components and maintenance may be required to keep the oil heated or cooled to an appropriate temperature so it can flow through the system as desired, ensuring consistent performance.

Electric actuators, on the other hand, are not typically affected by temperature. The actuators can overheat but that is often due to extreme changes in duty cycle, or it not being sized appropriately for the application. And if used in a cold environment there are greases which can be used to ensure performance.

Noise is another environmental factor to take into consideration. Hydraulic systems tend to be noisy, which could be a concern for machine operators. Minimizing the amount of noise emitted from a machine through use of a quieter electric actuator can increase safety and comfort for operators.

This helps create a more desirable working experience, an increasingly important aspect as manufacturing – like many industries – is struggling to find skilled workers. Offering a safe and comfortable work environment not only aids employee retention but also the ability to attract new potential employees.

Evaluating Total Cost of Ownership is Important

One of the biggest challenges associated with the switch from hydraulics to electric actuators is customers having knowledge and confidence in both technologies, said Tolomatic.

The company said there are many people who have been working with hydraulics for a long time but unaware or less comfortable with electric alternatives. Conversely, there are many people who are earlier in their careers and have grown up with electric technology which has provided them with a desire for more control and data collection, leading to a preference for electric actuators. They may also be less familiar with hydraulics which further influences their actuation technology choice.

More industry education on the pros and cons of each as well as working directly with a motion control technology supplier like Tolomatic can help provide a better understanding of both systems so a more informed decision can be made.

In addition, evaluating the total cost of ownership (TCO) associated with electric linear actuators versus hydraulic cylinders can help determine the best option for a given machine application. When doing so, Tolomatic points to the iceberg principle – the initial cost of a hydraulic cylinder-based motion system is less than that of an electric actuator one but there are more costs under the surface which can impact TCO.

Get to Know Industrial Hydraulic Actuators

Many industrial machines – such as metal presses, conveyor belts, cranes and others – need to move objects in a straight line which is achieved through use of a linear actuator. For decades, this linear actuator has come in the form of a hydraulic cylinder as it can provide the high force required of many applications.

These cylinders can have anywhere from a 1-8 in. bore and operate within a range of 2,000-3,000 psi (138-207 bar). They are also able to exert 1,700 to over 110,000 lbf (55 tons) of force.

Besides their high force capabilities, hydraulic cylinders are known for their durability and compact size. As hydraulic technology has existed for centuries, it is also a well understood technology.

As noted previously, hydraulic systems require more maintenance which leads to operational costs over the life of a machine. Energy used to power the system, disposal fees for the hydraulic oil as well as needing replacement filters on hand should all be taken into account when assessing the TCO of a hydraulic system.

While electric actuator systems cost more up front to install, they tend to have a lower TCO compared to hydraulics. This is due in part to the minimal maintenance required by these systems as well as their ability to perform more accurately and efficiently.

Per Tolomatic, electric actuator systems usually operate in the 75-80% efficiency range while hydraulic actuator systems are in the 40-55% efficiency range. The more efficient a system is, the less energy it will use and thus lower utility costs.

Related to this, electric actuators demand current only when needed so if at rest there is little to no energy being used. Hydraulic systems, however, require the HPU to be pressurized at all times to ensure the system is ready to work when needed which is not as efficient a use of power.

Efforts are being made by the fluid power industry to improve the efficiency of hydraulic systems as various industry sectors look to improve their energy use and overall environmental impact. These efforts, paired with the force capabilities and other aspects, will help to keep hydraulics in use for years to come where appropriate.

Tolomatic concluded that the list of applications which are moving from hydraulic to electric actuation continues to grow every year. The company said it is continually working with customers to address their unique application situations to ensure an electric actuator system meets all performance requirements. While a shift to electric is taking place in the industrial sector, Tolomatic also noted there will continue to be applications in which hydraulics and pneumatics are the right technical solution.

This is the first article in our series on the industrial machinery industry’s shift from hydraulic to electric actuation technology in collaboration with Tolomatic.

Read the other article in the series -

Converting from Hydraulic to Electric Actuators: Key Steps to Follow

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech