iVT Expo 2025: New Hydraulics Technology Launches on Display

Several companies from the hydraulics industry will be exhibiting at iVT Expo 2025, many of which intend to show their latest technological developments.

Taking place August 20-21 in Rosemont, IL, iVT Expo is an annual trade show and conference geared toward those who develop mobile off-highway machinery such as construction and agricultural equipment. OEMs, component suppliers, system integrators and others who serve the off-highway equipment are typically in attendance.

NFPA Partners with iVT Expo

The National Fluid Power Association (NFPA) announced it was partnering with iVT Expo in 2024 to help bring more hydraulics education and exhibitors to the event due to their importance to the off-highway sector. NFPA is partnering with the show once again in 2025.

As part of this partnership, NFPA will be hosting a Hydraulics Technology Conference during the event as well as offering members a discount on the registration fee. Sessions for the conference will highlight developments in hydraulics which aid with automation, electrification, energy efficiency and more. The association has also been encouraging member companies to exhibit at the event so they can showcase their technologies to the off-highway equipment development industry.

Conference sessions held during the event highlight the many trends, such as automation and electrification, driving mobile equipment designs while the trade show portion of iVT Expo provides an opportunity to see the various technologies engineers may want to utilize in their machine designs.

Hydraulics will be among the technologies on display because of their importance to the operation of mobile equipment. Following are some of the new hydraulics technology developments that will be on display at iVT Expo 2025.

Webtec CTA Hydraulic Flow Monitor

Hydraulic measurement and control specialist Webtec intends to show its CTA series hydraulic flow monitor which is now equipped with a 4-20mA output. The device is designed to monitor and transmit oil flow as well as temperature data.

Data is transmitted via a J1939 CANbus interface. Per the company, the addition of a 4-20mA (three-wire loop) analog output for flow reporting provides the ability to permanently install the CTA flow monitor onto industrial and mobile machines.

The 4-20mA output allows for easy integration into existing systems through its inclusion of the commonly utilized M12 connector for the monitoring device’s electrical port. Less wiring and connections are required for this output type, helping to simplify configuration as well.

Another benefit Webtec notes the 4-20mA output provides is efficient operation because this output’s loop current remains constant and does not degrade over distance. This also helps to reduce the chances of electrical noise and interference; the low current of a 4-20mA output eliminates the risk of electrical shocks.

Additional features of the CTA hydraulic flow monitor include:

- closed-loop control

- real-time diagnostics

- safety interlocks

- EMC compliance

- ability to withstand heavy vibrations

- predictive maintenance/Internet of Things (IoT) capabilities

- resistance to water spray/steam cleaning (IP6K9K rating).

New Caplugs Hose Protection Technology

At iVT Expo 2025, Caplugs plans to introduce its new hose protection technology, the SPAB Series. This hose wrap features a black exterior which reveals a bright yellow inner layer as it wears down.

Providing this visual indication of hydraulic hose wear makes it easier for machine owners and maintenance personnel to see that wear is occurring which could lead to performance or downtime issues if not addressed. This helps enable more proactive maintenance approaches to be put in place; the earlier wear or other issues are detected, the sooner they can be fixed, helping to avoid costly unplanned downtime.

The SPAB Series is made from HDPE (high density polyethylene) and features smooth, round edges to provide non-abrasive hydraulic hose protection. It is an easy-to-install hose protector equipped with anti-static and UV-resistant additives to enable use in a range of rugged applications.

Other features of the hose protector include temperature resistance from -51 to 79 C (-59.8 to 174.2 F), as well as resistance to acids, oils and solvents.

Bailey Showing Hydraulics for Work Trucks

Bailey intends to show for the first time its hydraulic technologies geared specifically toward the work truck market. These include hydraulic pumps, motors, manifolds and a number of other components key to the operation of work trucks.

Brianna Henderson, Senior Marketing Manager at Bailey International, told Power & Motion the company will be “showcasing hydraulic products designed specifically for work trucks, highlighting our focus on expanding into this market more aggressively.”

She said the company’s expansion into the work truck market is driven by the alignment of Bailey’s product offerings with market needs, the potential for growth, and a strategic focus on meeting customer demands and industry trends.

Dump trucks, utility trucks (also referred to as bucket trucks) and other vehicles in the work truck market rely on hydraulics for many of their functions from lifting and lowering dump beds to powering tools and auxiliary functions. These vehicles are critical to a number of industries and often work alongside off-highway machinery on various job sites; dump trucks for instance commonly work alongside excavators on construction sites to move material from one location to another.

And while work trucks have their own unique design requirements, many of the trends shaping hydraulic component and system designs for the off-highway equipment industry are also influencing the work truck sector such as the desire for increased efficiency, electrification and automation. Therefore, iVT Expo is a good event for Bailey to showcase its entry into the work truck sector due to the overlap in applications and technology needs between work trucks and off-highway machinery.

Bailey will also be showing its hydraulic and electronic technologies at the same booth which are all now under the same name, Bailey. Henderson said this will be the first time the company has presented a unified front by bringing its two divisions together. The company announced at the beginning of 2025 all of its brands - Bailey International, Sure Grip Controls Inc. and Hydrolico International – would be brought together into a single, cohesive identity to help show the range of hydraulic and electronic solutions it offers.

Wilkes & McLean Hydraulic Noise Suppressor

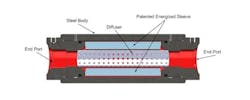

Noise suppression specialist Wilkes & McLean will show the newest generation of its inline hydraulic suppressor technology. The new Energized Sleeve line of suppressors uses the company’s proprietary hydraulically stable urethane foam to mitigate noise in hydraulic systems.

According to the company, this new suppressor can be used as a drop-in replacement for its bladder-style suppressors which have been used for decades to suppress hydraulic system noise. Similar to its bladder technology, the Energized Sleeve locally reduces the effective stiffness in a hydraulic system to minimize noise. However, the lack of a bladder in the new suppressor eliminates the need to perform regular maintenance which can help to save time and costs for machine owners.

Hydraulic systems are known to be noisy during operation which can be a comfort and safety issue for machine operators. And as electrification increases in many mobile equipment applications, reducing noise from hydraulics and other systems is even more important as there is typically no longer a large engine in the machine covering up the noise made by these systems as is the case in traditionally powered machines.

By using a suppressor like the Energized Sleeve, noises produced by hydraulics in all machine types can be reduced. In addition, suppressors can help minimize vibrations which might otherwise cause damage, extending the lifespan of hydraulic components.

Bosch Rexroth EDG-OBE Piloted Compact Directional Valves

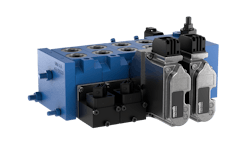

Among the hydraulics technologies on display from Bosch Rexroth and its HydraForce brand will be the new Bosch Rexroth EDG-OBE Piloted Compact Directional Valves.

The EDG-OBE is a sectional valve with onboard electronics. These electronics provide many benefits such as valve status monitoring and improved accuracy. Including onboard electronics not only benefits valve performance but also helps ease integration and electronics setup for OEM customers.

Aerial platforms, forklifts and agricultural cranes are some of the mobile equipment applications in which the hydraulic valve can be used.

Other technologies Bosch Rexroth and HydraForce will feature at iVT Expo include the EHBL Digital Boom Control Valve, Oil Condition Sensor developed in collaboration with Tan Delta Systems as well as the companies’ Compact Power Modules (i.e., hydraulic power units).

Next Generation Walvoil Adaptive Load Sensing System

Walvoil has developed a new line of Hydraulic Digital Solutions developed to meet the need for increased efficiency, automation and connectivity in mobile equipment applications.

Included in this digital technology lineup is the company’s Adaptive Load Sensing System, or ALS, the next generation of which will be on display at iVT Expo 2025. ALS applies software and electronic control to hydraulic pumps to help increase their efficiency and precision. The newest edition of the ALS system utilizes updated software and electronic control technology to further improve pump performance.

Walvoil will show its new Operating Assistance System for mini- and midi-excavators as well. It utilizes concepts from the robotics sector to enable automated control of excavator’s hydraulic arm. Sensors are integrated in the hydraulics system to enable this, helping to provide performance and safety improvements for machine operators.

Also on display will be Walvoil’s Energy Recovery Valve (EPX) which is a three-way device designed to limit actuator speed while also recovering stored gravitational and kinetic energy. Per the company, energy savings up to 20% can be achieved on a wheel loader through the combination of recovering energy and reducing compensation losses.

Wandfluh Compact Mobile Valve

Wandfluh of America will show its new valve range, the CMV(A) which stands for Compact Mobile Valve (Aluminum). The CMV(A) offers a modular design to provide mobile equipment manufacturers with an easy-to-integrate solution.

Valves in this product range are available as section modules or individual blocks, aiding design flexibility for equipment manufacturers and system integrators. The compact design of the CMV(A) valves helps to ease installation, particularly in space-constrained machine applications.

The compact design and aluminum construction of the valves makes them lighter in weight as well. This can help to reduce the overall weight of a machine, reducing its energy consumption which leads to efficiency gains.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: