Onboard Electronics Improve Performance for Bosch Rexroth Hydraulic Valve

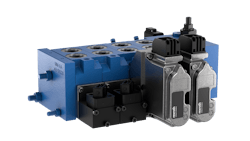

Bosch Rexroth has introduced a version of its EDG pre-compensated directional valve with onboard electronics, the EDG-OBE Piloted Compact Directional Valves. Including onboard electronics provides various performance benefits for the valve and the mobile equipment applications into which it is integrated.

Ross Johannes, Senior Application Engineer, Bosch Rexroth, explained in an interview with Power & Motion that the number of automated functions now on mobile machines is driving the need for the incorporation of onboard electronics.

Bosch Rexroth will be showing the EDG-OBE valve at iVT Expo 2025, an event geared towards engineers developing mobile off-highway equipment. Read more about other hydraulics technologies on display at the show in the article "iVT Expo 2025: New Hydraulics Technology Launches on Display."

Instead of relying on a human operator to command machine functions, computer control is used for those functions now being automated. “With that, we then need systems on components like onboard electronics so that the integrated microprocessor will control the function,” he said.

This enables the computer and microprocessors to continually check whether components are operating correctly, ensuring safe and accurate machine operation at all times.

With their onboard electronics, the EDG-OBE directional valves help with the implementation of automated functions while also offering a number of other benefits as well.

How Onboard Electrics Benefit Hydraulic Valve Performance

Johannes said the EDG valve itself is a power dense sectional valve with an integrated pre-compensator, and there are a wide range of accessory valves and options that can be utilized with it such as load sense pressure relief.

The inclusion of onboard electronics brings three key benefits he said:

- valve status monitoring

- reducing hysteresis

- simplified electronics setup.

As part of the onboard electronics, Johannes said there is an integrated spool position sensor. “That spool position sensor tells us if the valve is closed, open, or somewhere in between,” he explained. “When we have a very critical function, such as steering, we can see the status of the valve and make sure the valve is operating how we want it to.”

By reducing hysteresis, the onboard electronics essentially ensure the valve performs more accurately. Johannes said the onboard electronics enable the valve’s flow rate to be within 1% of the commanded value. “Without the onboard electronics and the spool position sensor, it's going to be more like plus or minus 5%,” he said. “So, our valve becomes more accurate.”

The final benefit Johannes pointed to is ease of integration and setup. Equipping components like hydraulic valves with onboard electronics helps to simplify both wiring connections and programming.

This ease of integration can be an important aspect for some OEM customers, particularly smaller equipment manufacturers who may not have a dedicated software engineering team. “Having that simplified setup can really improve their speed to market with a new machine by not having to go through intensive software design, reconfiguration or testing for valve-to-valve variants on machines,” said Johannes.

He went to explain that intrinsic to the construction of valves without onboard electronics is piece-to-piece variation, meaning there could be different clearances between the components or slight differences in friction. “That’s what leads to hysteresis or variances in how the valve responds.”

This can also cause changes in what he refers to as the threshold point. “That’s the point at which the valve truly starts to open with a given command,” he said.

With valve-to-valve variation, Johannes said an OEM may need to do some configuration work, set up software as well as set up threshold points and the correct ramping for each valve on a given machine.

But with onboard electronics, all that configuration and setup work can be eliminated. “Essentially, the onboard electronics inside each valve slice compensate for the piece-to-piece variation, and with that when end users are assembling a valve onto their machine, they can expect each slice to work the same way,” said Johannes. “The do not have to spend time changing the configurations and software personalities for small valve-to-valve adjustments.”

He said that if a machine includes a particularly precise function, setting up the required hydraulic personalities can be a time-consuming aspect of machine assembly. But having a valve like the EDG-OBE with its onboard electronics can really simplify that aspect of machine manufacturing.

Compact Valve Design Eases Installation Without Sacrificing Performance

Another key benefit of the EDG-OBE directional valve is its compact size. According to Johannes, it is one of the smallest in the industry for its flow class.

Components which are smaller in size can more easily fit into many of today’s space-constrained machine designs, easing installation for customers.

He said the design of more compact machines is a result of the progress that has been made in mechanical engineering over the years. OEMs have gotten very good at creating machine structures with no wasted materials, leading to less space availability for components like hydraulic valves.

“The smaller that you can make your hydraulic valves, the easier it is to fit them into our more compact machines of the future,” said Johannes.

He noted that while it may not seem like much when a valve’s data sheet says it is 10 mm smaller than another valve, available space in a machine is not a given so the ability to offer a smaller valve can help win a project in many cases.

Compact hydraulic components can also benefit weight sensitive machine applications. “We have lots of instances where control valves are on booms, elevated devices and machine structures where just the weight of the valving itself can essentially detract from the rated capacity of the machine,” he said.

The ability to provide a compact yet power dense valve like the EDG-OBE can enable small increments in machine performance by reducing weight without sacrificing performance.

A Hydraulic Valve for High-Pressure and Precision Applications

The high-pressure capabilities of the EDG valve as well as the incorporation of onboard electronics enable it to meet the performance requirements of various mobile equipment applications.

Johannes said the valve has a work port pressure rating of 350 bar (5,076 psi). This combined with the onboard electronics makes the EDG-OBE well suited for drilling functions in machines such as directional drills. Directional drills are high pressure machines with several functions to control, some of which, including the drill itself, require very precise control that the onboard electronics enable.

Therefore, directional drills and other similar types of machinery operating at high pressures which also have numerous functions to control — like small wrecking and demolition machines — benefit from use of hydraulic valve like the EDG-OBE that can meet their high pressure and control requirements.

Steering, particularly steer-by-wire, applications are another good fit for the EDG-OBE directional valve. Its inclusion of onboard electronics meets these applications’ requirement for a high level of precision and, in some use cases such as agricultural equipment, position monitoring on the valve itself, noted Johannes.

Semi-automated steering has been utilized in agricultural machinery for several years now, but its use in other heavy equipment applications is increasing along with other automated functions and systems. Much of this has been brought on by the need to make machines easier to use due to the difficulty in finding skilled labor to operate them. This challenge will persist, which is driving the need for more automation capabilities and components enabling them like hydraulic valves equipped with onboard electronics.

Johannes said steer-by-wire systems, path finding, automated leveling and other operator assist functions are more frequently being integrated into machines to aid ease of use and higher levels of automation. These operator assist, or fully automated functions, are “where this type of component [the EDG-OBE valve] with onboard electronics [and] its system state monitoring really starts to become more relevant,” he said.

He noted that electronics manufacturing around the world has become more sophisticated, which has helped bring down the cost of the technology. As such, its use in applications such as hydraulic components and system for mobile equipment has grown.

The affordability of electronics will be a contributing factor toward their continued integration into hydraulic systems in the coming years as well as the rising need for more automation and the other performance benefits which can be achieved with onboard electronics.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech