Hydrostatic Transmissions Offer Range of Benefits and Market Opportunities

What you’ll learn:

- The difference between hydrostatic transmissions and other transmission types.

- Why uptake of hydrostatic transmissions is increasing in the off-highway equipment industry.

- How development and integration of hydrostatic transmissions is evolving.

Hydrostatic transmissions have been used on various types of mobile equipment, such as tractors and compact track loaders, for many years. These transmissions utilize hydraulic pressure to transfer power and enable movement of a machine.

According to Tony Welter, President, Hydrostatics Division at Danfoss Power Solutions, hydrostatic transmissions offer a number of benefits compared to some other options such as greater design flexibility and high torque at low speeds.

Due to the many benefits offered, use of hydrostatic transmissions is increasing in various machine applications.

Power & Motion spoke with Welter about the growth Danfoss is seeing for the hydrostatic transmission market, how the technology compares to traditional mechanical options as well as how development of these transmissions has evolved over the years.

*Editor's note: Questions and responses have been edited for clarity.

Power & Motion: To start our conversation, how do you define a hydrostatic drive and how does it differ from other drive technologies utilized in the mobile equipment industry?

Tony Welter: I think the best way to describe it is to compare it to mechanical transmissions. Many people are familiar with [those], whether it be in their vehicles or on-highway trucks, where the prime mover — most of the time it's an engine — is connected mechanically to the drivetrain, to the wheels, shafts, gears and all those things that are efficient but take up space and sometimes don't work very well in off-highway equipment.

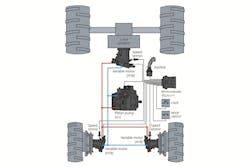

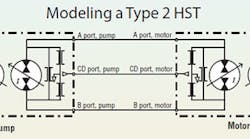

A hydrostatic transmission is basically a pump and a motor that's coupled via hydraulic hose, and fluid from the pump flows to the motor, turns the motor and turns your wheels in a very simplified fashion. There are some advantages to that in off-highway equipment, particularly as you think about the architecture of many vehicles. They don't lend themselves well to having an engine close enough, or in proximity, to the wheels for propulsion where mechanical transmissions work very well. And so, hydrostatics address that need and give [an OEM] the flexibility to design equipment how they might need it.

There are some other advantages of hydrostatic transmissions, which is, they’re a shiftless transmission. I can go from no speed to full speed without shifting. That's smooth, easy on the operator, less work, [and] less wear and tear. I can also go from full forward to full reverse very quickly. Again, no clutching, no shifting; and then I have lots of torque available to me at rather low speeds, I don't have to find the right gear. And so those are the big differences between hydrostatic transmissions and mechanical transmissions. As you might imagine, based on that value proposition, they're quite widely used in off-highway equipment.

Learn more about hydrostatic transmission technology in the below articles.

Power & Motion: Is Danfoss seeing a trend toward greater use of hydrostatic transmissions in mobile equipment applications due to some of those benefits they offer? If so, what is driving this trend?

Tony Welter: We see growth in the market, and I'll say it comes from two areas. One is in equipment that uses hydrostatic transmissions, those applications are growing. For example, compact track loaders and combines…that equipment is growing in the share of the [machinery] population because of their advantages in the marketplace. Tractors, particularly smaller tractors, use them as well.

There's also growth in areas where hydrostatic transmissions haven't been used previously, [because] maybe they've had a typical mechanical transmission with torque converter. We see those in applications like wheel loaders, [which] are now, particularly in North America, transitioning more to hydrostatic transmissions. And that's again [because of] the value proposition that I talked about earlier, [it being a] shiftless transmission, [and the] ease of going from full forward to full reverse very quickly, and some of the control benefits that we have. I think, ultimately, platforms that haven't used transmissions are looking at the full value proposition for the operator — that could be productivity, that could be fuel savings, that could be efficiency and how they do things, and the operator comfort piece.

We see hydrostatic transmissions being used in larger tractors now for those same benefits and other platforms like telehandlers that operate in rough terrain and need precise control and movement, it's quite valuable.

Again, those platforms that have been [using] hydrostatic transmissions…compact track loaders, sprayers [and] combines, we see good growth in those areas, as well as a share of the overall market space.

Power & Motion: You said you’re mostly seeing this growth in the North American market, correct? Is there a reason for that?

Tony Welter: My specific reference was for wheel loaders in North America. The reason for that is historically, the North American market has had a higher population of mechanical transmissions. Europe was earlier to adopt hydrostatic transmissions in some of their larger wheel loaders, and that's sort of an end user preference, they like to feel and control.

And now I think the value proposition for users in North America has [increased]. They like the functionality, and maybe some of the duty cycles are changing a little bit for them that we're seeing [hydrostatic transmissions] being adopted more in North America.

OEMs would tell you that from region to region there's things that are important to a customer in a vehicle, and that was one of the nuances in wheel loaders that Europe had more hydrostatic transmissions than North America.

Power & Motion: You already provided some examples of mobile equipment applications utilizing hydrostatic transmissions. Is it a technology that could be applied to just about any type of application or are there some these transmissions are more beneficial for versus others?

Tony Welter: Where you’ll find hydrostatic transmissions is in platforms that I'll call highly dynamic, that have a lot of back and forth, reverse, and forward [movements]. Large, high horsepower tractors that drive down a row for a long time don't have hydrostatic transmissions. Now, in some cases, they leverage the benefits in parallel transmissions that use some components of hydrostatics to drive the function of continuously variable transmissions, for example. But generally, it's these highly dynamic back and forth, running into dirt piles [applications], or where precise motion control is needed that you'll see hydrostatic transmissions.

I talked about some of the platforms where we see things expanding; I think that [will] continues as the value proposition of not shifting, or the inefficiencies of shifting as compared to a mechanical transmission become bigger issues for a platform.

There is some growth and it's really all driven by what operators deem important and what they value in the application.

Power & Motion: How have you seen hydrostatic drive technology evolve in recent years, and what further technological developments do you foresee, or think are necessary, in the future?

Tony Welter: It’s an exciting time in hydrostatic transmissions, I think, within the Danfoss business and broadly for our industry. The biggest change that I've seen is as we think about how we integrate hydrostatic transmissions into a vehicle platform. At Danfoss, we take a full system solution approach. If we think hydrostatic drive is right for a machine platform, we want to look at the entire platform — what it does, how it operates — to understand what might be best in terms of the control settings, the configuration of that transmission to provide value for the end user, whether that be fuel efficiency or productivity.

One example that I would use is in the past, we would [supply] a transmission and maybe it was driven manually. That's levers, mechanical linkages to the pump, [and] it took strong arms and some experience in order to control a vehicle well. In the last [10 or so] years there has been a lot of integration of electronics. Rather than mechanical linkages, you have electronic control, which is a phenomenon I think we see across the hydraulics industry, not just in the hydrostatic transmission portion of it. But what I would say is a more recent development is the approach where we look at the entire vehicle, and particularly for the hydrostatic transmission, we look at the engine and say how can we run the engine in its most ideal form? Because we have some options in how we control the transmission, [in terms of] speed and pressure, we have motors and pumps that are both variable, so there's different modes that we can operate in conjunction to get the same output.

We will work with our OEM partners to [determine] where the engine that they spec’d operates most efficiently and then we'll run our hydrostatic transmission in the zone where the engine is most efficient. We can do that because we know ultimately what the operator is commanding, for example, if it's speed that the operator wants or performance the operator wants, and we pair that with the infinite amount of configurations in terms of pump and motor displacement, and combine that with the engine to get an output that is the most efficient. So, you not only have a control that's better for the operator, you also have one that's better in terms of fuel efficiency which is of large value to the end users.

I think that work will continue, the integration of engine and hydrostatic pump and controls. You need all three [working] together. In the past, the OEMs had engines and we’d spec the hydraulic system with less thought about how they integrate. Now, with a deep understanding of how the engines work, how they operate, their efficiencies, the ability to control both the transmission and the engine via software, there's options that we didn't have in the past for that controllability. And then paired with highly efficient components in the transmission and product that's enabled with electronics, all three of those things come together to enable the most recent advancements over the past few years.

But I think that will continue; the level of expectation from our customers will only get higher in terms of their performance and efficiency expectations. In some cases, we're pushing the limits of physics for the efficiencies of our components, whereas we think probably the biggest opportunity looking forward is at the system level.

Power & Motion: You were talking about making sure the engine and transmission work efficiently together. As the mobile equipment industry moves toward electrification and use of battery powertrain systems, do hydrostatic transmissions still have a place or will different drive technology be used?

Tony Welter: Today, our pump marries to an engine. In the future, is there a battery [or] an electric motor that spins the pump? Yes, that's definitely one option, and I think then everything that I talked about still applies in that [scenario]. And maybe we actually have some more options because of [our] understanding of battery load, battery charge, just as we think about engine RPM, fuel efficiency, those types of things. It’s very analogous on that front.

As we think about electrification, some might [think] replace that hydrostatic transmission with an electric generator and a motor, just take the hydrostatics out of the picture. And yes, there will be some applications that do that. We see some of that today in some of the smaller, lower horsepower applications where I'll say propulsion is not a core aspect of what the customer buys the vehicle for; maybe it's just to get from the trailer to the work site. But in other cases, there are customers that want a full electric solution in place of the hydraulics. Most OEMs now have an offering in most spaces of full electric vehicles, and in some cases, they've replaced the hydrostatics. We think there'll be a place for that in the market, and that trend will grow over time, but there's still a value proposition for hydrostatics in terms of its power density, its robustness, and cost today that electrics can't provide. So, there's a core part of the market that we believe will remain hydrostatically driven for quite a while.

As electrics advance in this space, we too will advance. Even here at Danfoss we have electric propulsion solutions. We look at what's the right solution for the platform, take a technology agnostic position on that; each of our divisions and component sources look at a platform with their depth of expertise and make a pitch for what has the best value. I think that positions Danfoss quite well in this space [because] we have hydrostatic transmissions…and also electric solutions via our Editron product portfolio to address [requirements] for a full electric solution.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: