Axial Flux Motors: Understanding Their Benefits and Application Uses

What You'll Learn

- How the design of axial flux motors differs from conventional electric motors and the benefits this provides.

- The varied applications in which axial flux motors are being used to aid the creation of hybrid- and full-electric vehicles.

- Why axial flux motors are a good fit for electrifying hydraulic systems and the advantages of doing so.

Electrification of various vehicle and mobile machinery applications has introduced a range of technologies to the market, including different types of electric motors which play an important role in powering many of the systems in an electric vehicle.

Axial flux motors are one such electric motor technology increasingly being utilized in hybrid- and full-electric systems.

According to data from Valuates Reports, the global axial flux motor market is projected to achieve a compound annual growth rate (CAGR) of 66.7% by 2031. Use of axial flux motors is on the rise in applications including aerospace, on- and off-road electric vehicles, and industrial machinery because of the many performance benefits they offer such as high torque density and energy efficiency.

Why This is Important

For those developing fluid power and other systems that will be utilized in electric vehicles and machines, it is important to understand how various electrification technologies like axial flux motors work to ensure all systems will work together properly to achieve desired performance requirements.

As use of axial flux motors increases, it is beneficial to have an understanding of how these components work, the advantages they can provide as well as the applications for which they are best suited.

The Benefits of Axial Flux Motors

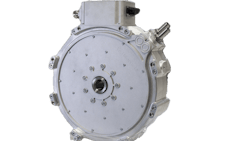

Axial flux motors are characterized by their magnets being mounted in the opposite direction on the rotor than they would be in a conventional motor design.

Chris Pearce, director, advanced engineering development at Turntide Technologies, explained in an interview with Power & Motion that in a conventional motor, “the magnets are on the rotor, and the flux comes up from the ground at 90 degrees from the axis of rotation and back into the motor.

“In an axial flux motor, the flux of the magnets actually comes from the same direction as the axis of rotation. And above a certain radius, this starts to have a huge incremental advantage [on] torque density,” he said.

Because of the way the magnets are mounted, a smaller form factor similar in shape to a pancake can be achieved. “You can get a huge amount of torque output and power” from a more compact motor design which can be especially beneficial in applications where space is a concern said Pearce.

Construction equipment and other heavy-duty mobile equipment applications are one such example. Space is already at a premium in many of these machines which can make it difficult to install electric motors, batteries and other electrification-related technologies, especially if retrofitting into existing machine designs. As Pearce explained, because many machines were originally designed to include an internal combustion engine and its ancillary equipment, there can be some awkward spaces in a machine being transitioned to electrification.

Turntide Technologies has launched the Axial Flux Electric Drive Unit (EDU) to further ease implementation of electric propulsion. Debuting at CONEXPO-CON/AGG 2026, it provides customers with a fully integrated and validated system comprised of an axial flux motor and all other necessary components.

However, axial flux motors can more easily fit into these spaces because of their compact design. Conventional electric motor types in the same power class tend to be longer and bulkier which can make them more challenging to install.

The power density and efficient operation offered by axial flux motors — due to their reduction in iron and copper losses — also help make them a good fit for heavy-duty mobile equipment and other similar applications with high power needs.

Another benefit of axial flux motors is their ability to be scaled. “We can actually stack up the motor along the axis; we can double up the amount of rotor [and] stator combinations and double the output power with only a moderate increase in volume,” said Pearce.

In general, he said axial flux motors are a “very powerful prime mover option if you are constrained for space and looking for something really efficient.”

He noted Turntide’s axial flux motors also offer a high level of customization in terms of connectors as well as inlet and outlet orientations that can be beneficial for customers.

The motors are cooled using a water ethylene glycol solution instead of oil cooling as is the case with other electric motors in the market. Nathan Martinez, field applications engineer at Turntide Technologies, told Power & Motion the benefit of using water cooling is that the same cooling system can be used for the inverters and motors in a hybrid or electric vehicle. “You [do not need] to have a separate oil-cooled system and a separate water-cooled system,” he said. “You're saving energy, weight, and integration [which is a] big benefit.”

Application Uses for Axial Flux Motors

There are a wide range of machine and vehicle applications in which axial flux motors can be utilized such construction equipment and other mobile off-highway machinery, commercial vehicles, powersports and more.

Martinez said Turntide sees a lot of use of axial flux motors for traction drive applications to enable electrification in verticals outside of automotive, such as mobile off-highway equipment. This is commonly achieved by either mounting the axial flux motor on a transmission or using it as a hub motor.

A newer use case that has emerged is using the axial flux motor in generator applications. He said customers are mounting the motor onto diesel engines to create a hybrid that can charge batteries or power auxiliary functions such as a cooling system on a truck or a hydraulic lift.

For the latter, Martinez pointed to scissor lifts as an example. In this application, an axial flux motor can be used to drive the hydraulics which enable the lift to move up and down instead of an engine, leading to reductions in noise, emissions and fuel consumption.

Electrifying Hydraulic Systems with Axial Flux Motors Provides Potential for Efficiency Gains

Electrifying hydraulic systems of any type opens up a number of design possibilities noted Pearce. Using a diesel engine as the prime mover means there was only one solution used but now there are hundreds of configurations that can be considered to electrically drive pumps and other hydraulic components.

Axial flux motors are a good option to consider when looking to electrify hydraulic systems. They can provide the power necessary to drive hydraulic pumps at the speed and torque required in many applications while offering a small form factor for easier integration.

Pearce explained that when electrifying a hydraulic system, you can now regulate your individual pumps to operate at their most efficient operating point for the given demand requirement of the application.

“If you've got multiple pumps all with different demands coming from a central control unit, then that [control unit] can [determine] what the optimized speed pumps should run at to get the power required for the hydraulics,” he said. “It's all about how you control that machine to give the absolute maximum efficiency.”

Efficiency is one of the main benefits of electrification, said Pearce, because it can lead to reductions in fuel consumption, and thus costs, as well as lower emissions output.

Read our articles below to learn more about the increasing development of electrically driven hydraulic and pneumatic pumps.

In larger machine or vehicle applications that are difficult to fully electrify, having the ability to electrify systems and subsystems like the hydraulics makes it easier to achieve some of the efficiency gains and other benefits of electrification.

Going forward, Turntide sees continued opportunities for axial flux motors in both hybrid- and full-electric applications, although the company is seeing hybrid systems rise in popularity because it is a more feasible option for achieving the benefits of electrification in some vehicle and machine types.

Martinez said many are now seeing the benefits of electrification outside of decarbonization. Though still an important factor for some customers, for those in construction or other similar applications in which a vehicle or machine is used for work, there needs to be a good business case for going electric such as helping reduce fuel costs.

He said customers are realizing this potential when using systems equipped with an axial flux motor because it maintains the power capabilities they are used to while offering benefits such as reduced maintenance through fewer wear parts, efficiency gains and weight savings — which can play a role in reducing fuel use.

Martinez concluded by saying there are still customers interested in electrification but instead of government incentives or corporate initiatives driving that interest as it was for many in the past, now it is the fact that they have realized electrification — in whatever form — makes sense from a business perspective in certain applications.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech