Integrated End-of-Arm Tooling Eases Installation and Robot Deployment

What you’ll learn:

- Why robotic end-of-arm tooling is becoming more integrated.

- The benefits provided by integrated end-of-arm tooling.

- How pneumatics will continue to evolve for future robotic tooling designs.

Automation in various industries often includes the deployment of robots to help complete tasks such as welding and moving objects from one location to another. A key component of these robots is their end-of-arm tooling (EOAT) which is the part that interacts with objects.

Today’s EOAT — including grippers, vacuum cups, tool changers and more — are becoming increasingly more compact and integrated to help ease installation while also saving on weight and space claim.

Anuj Bihani, Founder & CEO of Impaqt Robotics, said the trend toward more integrated grippers and other EOAT technologies is growing quickly. “As automation becomes more accessible, customers expect EOAT solutions to be easier to integrate, more modular, and faster to scale,” he said. “The move toward plug-and-play tooling is being driven by a need to reduce engineering time and lower deployment risks. This is even more relevant for small to mid-size manufacturers who may not have large in-house engineering teams.

“The growth of collaborative robots is also accelerating this trend, where compact, efficient designs are critical,” Bihani continued. “Traditional EOAT setups with multiple components can act as bottleneck to quicker robot deployment.”

“Unquestionably, the trajectory of robotic end-of-arm tooling is firmly set towards greater integration. This evolution is not merely a fleeting trend but a fundamental reshaping of automation, fueled by the relentless demand for higher output and leaner operations,” said Fabio Bottarelli, Head of Product Management at Camozzi Automation. “The demand for solutions that streamline deployment, maximize robot utilization, and minimize complexity is the key catalyst.”

In this article, we examine some of the integrated EOAT being developed by Camozzi and Impaqt Robotics, the benefits offered by these devices, as well as the role pneumatics will continue to play as robotic end-of-arm tooling technology evolves.

Integrated Components and Intelligence Benefit Pneumatic Gripper Performance

In 2024, Camozzi launched its CSSP pneumatic collaborative parallel gripper which features an integrated design. Bottarelli said key integrated components in the gripper include control valves, end-of-stroke sensors, and a simplified connection with a single air inlet and electrical supply.

By integrating all of these components into the gripper, a more compact and lightweight solution can be achieved which is “crucial for optimizing robot payload and reach,” he said.

“Integration simplifies installation and reduces the need for external components, streamlining setup and minimizing potential interference,” said Bottarelli. “Furthermore, it enhances responsiveness and precision, contributing to increased efficiency and productivity in robotic applications.”

With its more integrated design, the CSSP gripper provides a plug-and-play device which eliminates the need to source or install additional components, providing faster and easier set up.

Bottarelli said the CSSP gripper’s plug-and-play functionality with collaborative robots from ABB, Fanuc and Universal Robots, combined with an intuitive interface, “eliminates complexity and accelerates deployment. And with versatile control options, the CSSP adapts effortlessly to any automation scenario.”

Machine tool tending, end-of-line packaging and assembly are some of the applications in which the CSSP gripper can be utilized.

Safety was a key aspect built into the robotic gripper as well. Bottarelli said it was designed in with features such as a protective cover and controlled force to ensure harmonious human-robot interaction for compliance with ISO TS 15066. As part of its safety features, the gripper will maintain a workpiece in closing or opening position should a pressure failure occur.

Built-in intelligence is also a key component of the CSSP gripper design. He said this is achieved by weaving in advanced sensors — like workpiece presence detection — sophisticated control systems, and seamless communication. Such technological integration is needed to meet the market’s desire for robots that can adapt on the fly, make informed decisions, and provide real-time insights, explained Bottarelli. As such, he said Camozzi is “fully embracing the rise of smart, intelligent robotic grippers.

“Smarter robotic grippers deliver game-changing advantages,” he continued. “Imagine having access to real-time data on every grip, enabling your robots to adjust automatically and prevent errors. The result? Pinpoint precision, minimal damage to valuable parts, and rock-solid process reliability. Ultimately, this translates to faster cycle times, greater throughput, and a significant boost to your bottom line.”

Overall, the CSSP gripper is about enabling smart, efficient and safe automation, said Bottarelli.

Watch Camozzi's video below to learn more about the CSSP pneumatic collaborative parallel gripper.

Pneumatic and Vacuum Come Together in a Single Device

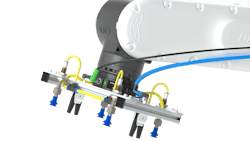

Impaqt Robotics, a developer of pneumatic tooling for robots, has created an EOAT which brings together pneumatic and vacuum technology in a single device called pneuvaQ. Bihani said development of the tool came about from difficulties sister company Alstrut often experienced when tasked with creating EOAT with both vacuum and pneumatic functionality.

This job was usually slow, complex and difficult to scale, he said. “Each project involved custom integration, sourcing multiple components, managing intricate layouts, and troubleshooting compatibility issues,” Bihani explained. “Seeing these recurring barriers firsthand, we recognized the need for a standardized solution that could eliminate the complexity.”

In conjunction, collaborative robots were gaining popularity due to their promise of simplified and flexible automation, he noted. “However, even simple EOAT requirements often resulted in disproportionately high engineering effort — slowing down deployment and limiting the ability to scale cobot applications.”

So, the company set out to overcome these challenges and streamline EOAT integration by combining pneumatic and vacuum control into a modular, compact interface. “This approach allows integrators and manufacturers to build and reconfigure tooling faster, without needing to start from scratch each time, ultimately reducing engineering effort and accelerating deployment,” said Bihani. “It reflects our vision to accelerate global robotics adoption by simplifying deployment and making advanced automation accessible to all.”

pneuvaQ manages compressed air flow, pressure, and direction for both pneumatic and vacuum tools through a single compact unit. Bihani explained that instead of running multiple tubes and setting up separate valves and control boxes, users only need one compressed air inlet line and one communication cable. Internal routing and embedded control electronics are used to handle both functions. “This architecture reduces external complexity at the robot arm and shortens setup time significantly,” he said.

Typically, multiple air tubes and separate PLC (programmable logic controllers) controls are required to manage pneumatic and vacuum circuits. By instead integrating these controls and utilizing a single air inlet for both functions, the amount of wiring and tubing can be reduced to help create a more simplified design which minimizes the amount of manual work previously required.

The more integrated design also helps to reduce debugging efforts, enabling a faster transition from concept to deployment. “It also enables more modular, plug-and-play designs, which are easier to scale and replicate across multiple systems,” said Bihani.

“The industry has been asking for easier, more modular tooling solutions that eliminate unnecessary engineering overhead,” he said. pneuvaQ helps meet this request by providing a more efficient and scalable option for both integrators and end users.

Pneumatics Will Remain Important to End-of-Arm Tooling

While EOAT can be powered by electric, hydraulic, mechanical or pneumatic technologies, the Association for Advancing Automation (A3), states that pneumatics is the most popular option due to its ease of use and ability to provide a lot of power in a small package.

Both Camozzi and Impaqt Robotics see ongoing value in this fluid power technology as well. Applications requiring speed, force and ruggedness will continue to rely on pneumatics, said Bottarelli. “It's a cost-effective workhorse, particularly for repetitive tasks, and its impressive power-to-weight ratio keeps robot arms agile and efficient.”

Bihani agreed that pneumatics remain a dependable actuation method for high-speed, repetitive applications. He also noted that as use of cobots and modular automation grow, so too will demand for lightweight, adaptable EOAT. “Pneumatics fit naturally into this landscape, especially when combined with smart control solutions like pneuvaQ, which simplify integration and enhance functionality. Rather than being phased out, pneumatic systems are evolving to support the next generation of agile, scalable robotics.”

Bottarelli said pushing the boundaries of precision control, miniaturization and energy efficiency are ways Camozzi will continue to evolve its pneumatic gripper technologies to meet the requirements of next-generation robotics. “By seamlessly integrating sensors and smart controls, we're creating pneumatic grippers with unprecedented intelligence and adaptability. Expect lighter, more compact, and incredibly versatile pneumatic solutions that will redefine what's possible in robotic automation.”

Impaqt Robotics sees a similar trajectory for pneumatics to meet future EOAT needs. Bihani said pneumatic systems will become more modular, integrated and intelligent. “In the future, we expect pneumatic technologies to further integrate sensing, smart diagnostics, and digital communication interfaces. These enhancements will allow pneumatic EOAT to seamlessly plug into Industry 4.0 environments, offering better visibility, easier troubleshooting, and enhanced control, while retaining the core benefits of speed, robustness, and scalability,” he concluded.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: