How Advanced Hydraulic Control Valves Benefit Machine Performance

What you'll learn:

- The advantages advanced hydraulic control valves can offer over other valve types.

- How use of advanced hydraulic control valves can benefit mobile off-highway machinery.

- Where advanced hydraulic control valve technology is headed in the future.

Control valves are an important part of hydraulic systems as they regulate fluid flow to control direction, pressure and flow rates. Proper control of these attributes ensures an excavator arm or other machine system will function as desired.

According to Bruno Russo, Product Sales Manager, Mobile Valves at Bosch Rexroth, advanced hydraulic control valves offer many benefits in terms of independent load sensing to better determine how fluid flow is regulated. This leads to improvements not only in control but also efficiency and ease of use for machine operators.

Power & Motion spoke with Russo about what differentiates advanced hydraulic control valves from other valve technologies in the market, the various benefits they can provide off-highway machinery applications as well as the continued growth potential for these hydraulic valves.

*Editor’s note: Questions and responses have been edited for clarity.

Power & Motion: How would you describe an advanced hydraulic control valve, and what makes it advanced or different from other hydraulic valves?

Bruno Russo: In mobile off-highway equipment, reliability and efficiency are important to ensure important load-sensing hydraulic valves are utilized to deliver flow according to demand. The independent load sensing capabilities of advanced hydraulic valves are essential in changing how much energy savings and flow is ultimately utilized.

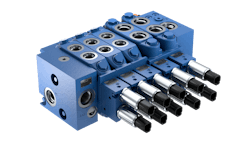

Compared to general directional valves in mobile machinery, advanced hydraulic control valves are designed for simplicity, with adaptability as a notable feature with modular design and easier operation.

At Bosch Rexroth, we have advanced hydraulic valve solutions in our RM valve portfolio that work to meet the precision and flexibility requirements of the off-highway industry. One of the greatest benefits of the load sensing control valve is that it automatically adjusts pressure and hydraulic force to the external load to ensure optimum operational efficiency. This load independence allows for supplemental energy savings from the flow demanded by large range and medium-duty machines.

Power & Motion: What are the benefits of using advanced hydraulic control valves, and what design aspects of the valves enable these benefits to be achieved?

Bruno Russo: There are numerous benefits in utilizing advanced hydraulic control valves, but the most notable include efficiency, adaptability and overall simplicity for operators.

Efficiency

Load sensing hydraulic valves are more efficient in an overarching system due to energy savings from the ideal flow demand and independence on the load for machine movement. These energy savings can improve the overall performance of a machine and decrease fuel consumption all while improving machine output.

Adaptability

One of the key design aspects of advanced hydraulic valves is their modularity. The sectional valve can be reconfigured for suitability across many applications across diverse types of off-highway machines. Additionally, the reduced weight and smaller dimensions are very advantageous in terms of the machine’s overall weight and required installation space.

User-friendly simplicity

OEM’s and operators often find that the advanced hydraulic valves are much simpler to assemble and operate. Due to the closed-loop nature of the electronic control (joystick to electronic control unit [ECU], ECU to the control valve with feedback position sensor and on-board electronics [OBE]), joystick control is more precise. This requires less skill needed to operate the machine in response to the load independence.

The reduction in component count helps all of these features integrate into the control valve. Some valve features can also be integrated on the electronic control side with software. The hydraulic control valves controlled proportionally can have several control modes integrated into the software. Due to the new valve design, there can be less components in the machine, meaning there can be lower leakage compared to past valve technology.

Power & Motion: What are some of the key features customers are looking for today from hydraulic control valves, and how can advanced control valve options meet these requests?

Bruno Russo: A lighter and more efficient machine is a major benefit to operators for many reasons, which makes advanced control valves so desirable in off-highway mobile machines. Many of these machines experience extreme temperatures, start-and-stop or constant pressure, which is maximized with a simple change in valves.

Additionally, software and sensors can be integrated with advanced control valves and give machine diagnoses and information for predictive maintenance, such as pressures losses, to spot concerns before they become problems.

Power & Motion: What types of systems and/or applications do you see advanced hydraulic control valves being utilized most? What is driving use of these valves in these applications?

Bruno Russo: Skid loaders, compact track loader (CTL) machines, cranes and other road construction machines are popular applications for advanced hydraulic control valves. These machines require a large amount of accuracy to operate effectively, so it is desirable to operators that can benefit from the valves’ lighter weight and simple maneuvering.

Additionally, forestry and agricultural machines benefit from using this solution due to the need for precision and the start-and-stop nature of a machine's work. With the resulting reduced component count on a machine from using these control valves, large pieces of equipment can move more efficiently on the job.

Power & Motion: How do you see the use of advanced hydraulic control valves evolving in the coming years – will their uptake continue to grow, and if so, what will help drive this growth?

Bruno Russo: Uptick in use will likely continue to grow as OEMs are increasing their use of advanced hydraulic valves with electronic controls and sensors included. This will improve machine operational efficiency, scalability with various controls that are easily configurable, optimization of use for low power consumption and energy savings for greater sustainability and more safety control.

The comprehensive trends impacting the off-highway mobile machine industry will drive growth in the upcoming years as these technologies become more useful and integrated.

Power & Motion: What further technological developments do you foresee occurring in the hydraulic control valve industry, and how, if at all, will they continue to become more advanced?

Bruno Russo: Hydraulic control valves for mobile machinery are already being developed at a high level for some applications, such as control valves with on-board electronics on tractors. It’s likely that this demand will continue to grow for construction, material handling and forestry machinery as we are currently experiencing. This will also lead to the next generation of smart valve connectivity for on-the-fly parametrizations, diagnostics, preventive maintenance, and more.

Developing a unique platform control valve that could combine all the best-known technological advantages (such as pre- and post-compensation for flow-sharing control, open- and closed-center control for low pressure losses) with the flexibility to be used as needed, could be a positive advancement for customers.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: