Why Steering and Drive Systems are Transitioning to By-Wire Technology

Steering and drive related technologies have traditionally relied on fluid power components, particularly hydraulics. But electrically controlled options, known as by-wire systems, are increasingly taking the place of hydraulics and pneumatics in various applications.

There are numerous factors driving this technological shift including the ability to improve vehicle performance, especially in terms of safety and control, as well as the increasing development of electrified and automated vehicles.

A range of electronic options are now available in the market, offering new design opportunities for OEMs in both the passenger car market and the heavy-duty on- and off-highway sectors.

How By-Wire Technology can Benefit Steering and Drive Systems

By-wire systems are those which use electrical or electronic control instead of a mechanical linkage (see sidebar). They can include drive-by-wire, brake-by-wire, and steer-by-wire, among others.

What is a by-wire system?

“By-wire systems are those with no mechanical connection back to the control mechanisms from the driver to the steering or the pedals. It’s all electronic,” explained Peter Dow, Vice President of Engineering at REE Automotive.

Traditionally, driver input has been transferred mechanically to a vehicle’s motor and wheels via a steering wheel, hydraulic brakes and other components. But with by-wire systems, these inputs are instead processed and communicated to the appropriate components by an electronic control system.

This enables opportunities for improved safety as the electronic controls can often react faster or even override human inputs to ensure the safest maneuvers are taken. In addition, the move to a by-wire system allows many components to be eliminated – such as steering columns, pumps and hoses – leading to lighter weight and more efficient vehicle designs.

Use of these systems in the automotive and aviation industries has increased over the years due to the many benefits they can provide. As the technology has advanced, its use is increasing in a range of other industries as well including heavy-duty vehicles.

Technology company ZF Friedrichshafen AG stated in a press release announcing the launch of its new brake-by-wire system that replacing the hydraulic braking system with an electric option reduces assembly and logistics costs because the system has fewer parts. The lack of hydraulic fluid also minimizes maintenance needs.

In addition, the company said moving to a purely electronically controlled and networked by-wire system offers performance benefits including better vehicle control, shorter stopping distances, greater driving stability at higher speeds and more.

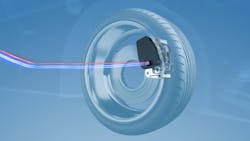

ZF’s brake-by-wire system generates braking force at each wheel using an electric motor and all signals from the vehicle’s pedals are sent electrically. Automatic emergency braking is possible with this type of system and capable of achieving braking distances 9 m shorter than conventional braking systems at speeds of 100 km/h. For electric vehicles, this type of system improves braking energy recovery to help increase the range up to 17%.

Wearing of brake pads and discs is minimized as well because there is limited contact with these components and reduced residual drag torque – which occurs with conventional braking systems – leading to a longer life and lower maintenance costs.

X-by-Wire System Benefits Design

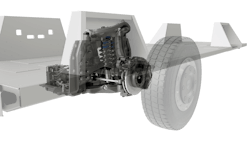

REE Automotive is an e-mobility company which has developed an x-by-wire system integrating steering, braking and driving into a single unit known as the REE Corner. All of the necessary elements for propulsion, steering and braking are contained in a single unit which can be placed on any of the four corners of a vehicle.

Peter Dow, Vice President of Engineering at REE Automotive, said there has been a shift toward by-wire systems because of the control and safety they can provide. “People get scared when they hear by-wire and think it's not going to be safe,” he said. “It's actually the opposite. It's much safer because you can put so many levels of redundancy and safety within the system, and you can control more.”

Safety is ensured by designing mechanical, electrical and software redundancies into the REE Corner. For instance, the unit’s 48V steering system is driven by an electric actuator which allows for 30 degrees of steering left or right. Dow explained that within the actuator there are two electric motors instead of a single motor, as is commonly done. If one of the electric motors should fail, the other one is still there to ensure the vehicle continues to operate as it should.

Precise measurement of the actuator is possible as well, enabling improved control capabilities.

The use of electronics along with the system architecture help to improve response time of the brakes, enabling vehicles to stop faster and thus operate in a safer manner. In addition, Dow said that because a vehicle will be equipped with four identical REE Corners, four-wheel steering is possible – enabling even the rear wheels to be steered – which can provide better maneuverability for larger vehicles and lead to improved safety.

He also noted the lack of a physical connection between the steering wheel and the vehicle’s front and rear wheels. Instead, electronics communicate driver inputs which Dow said allows for more fine tuning of the effort needed to steer the vehicle.

This can help make vehicle operation easier and open up the pool of potential candidates who could work in the transportation industry. “We talk about driving our vehicles not fighting them,” he said. “So to drive a big truck you don't need to have big biceps, you can drive it much more like a standard car or an SUV.

“We've seen with by-wire systems it opens up opportunities for people [and] it opens up what you can do with vehicles – bringing more comfort, safety and flexibility,” he continued.

READ MORE: Danfoss Partnership Yields First Completely Joystick-Operated Combine in Europe

With a by-wire system, it is also possible to implement automation. As Dow explained, there is a centralized control system which collects and sends all of the necessary electric signals, and it doesn’t matter if the inputs it receives are from a human driver or an autonomous system – they are the same because of the use of electric control, making it easy to implement autonomous operation if desired.

Electrification Growth Pushes New Drive Options into Market

Scott Wilmoth, Marketing Manager at Hydro-Gear – a developer of hydraulic and electric drivetrain solutions for lawn and garden and other off-highway applications – said each year the company receives more inquiries about electric options. “Everyone sees that electrification is coming,” he said. “This trend is not going away but neither are hydraulics.

“It is likely that hydraulics will remain the dominant choice in our industry for many more years and we still see significant opportunities for innovation and growth on the hydraulic side,” he continued.

However, because there is also increasing interest in electric drive solutions the company is continually developing both types of components to provide customers with the options that will best suit their design requirements.

In October 2023, Hydro-Gear introduced its latest electric drive solution the HGMe which is an electrified version of the company’s HGM hydraulic wheel motor. Wilmoth said it uses the same hydraulic geartrain as the HGM version because customers are familiar with the technology, and it has been proven in the industry. The difference is the attachment of the company’s in-house developed brushless DC motor.

Various sizes of the electric motor are available to meet specific customer application requirements which Wilmoth said is possible by varying the stack height. In addition, the motor can be wound for different voltages. The HGMe will debut as a 56 mm stack wound for 48V operation.

A key design criterion for the new HGMe was making it easy for customers to transition to an electric solution. Its similarities to the hydraulic version enabled this. In addition to using the same geartrain as the original HGM, the electric version fits into the same frame sizes making it an easy drop-in replacement.

Wilmoth said the company foresees a lot of interest in the new product, particularly from the commercial space, as more electric-powered machines are brought into the market. Electrification is still a niche for Hydro-Gear’s core market of the lawn and garden sector but as regulations increase and benefits such as lower operating noises are realized, the uptick in electric-powered machines will continue, necessitating electric drivetrain solutions.

One area he said the company sees there being more interest in electric over hydraulic options is in specialty applications, including those in which an electric vehicle is designed from the ground up to take advantage of the inherent benefits of electrification.

READ MORE: Design Considerations for Electrification and Fluid Power

Hydraulics Will Continue to Play a Vital Role

As Hydro-Gear’s Wilmoth noted, there are still customers who want to use hydraulics as part of their steering and drive systems because of familiarity with the technology or electric options do not yet meet an application’s requirements.

There is also the option to use hydraulics as part of an otherwise electrically controlled system which can help with market uptake. This is a key reason REE continues to use the technology for its REE Corner’s braking system.

Although the brakes are electrically controlled, conventional hydraulic braking is utilized at the actual wheel of a vehicle said Dow. “The wheel itself is controlled the same way a conventional hydraulic braking system is apart from the hydraulics, which are…being driven by an electric actuator [instead of] a pedal,” he explained.

While much of what’s contained in the REE Corner is comprised of electronics, components outside of it such as the suspension and braking system are standard designs that would be found on any other vehicle. “We want dealers and customers to be able to use the same technicians,” said Dow. “We’re trying to bring something [to market] that is new but reliable.”

Using industry standard designs means customers and technicians will still understand how to service the vehicle when necessary. “They know how to change brake pads, they know how to do inspections on them,” he said. “We’re not giving them something that’s completely new.”

Hydraulic solutions are likely to stick around for the foreseeable future in steering and drive systems, in some capacity, but as electric options continue to increase and advance in capabilities, there will be new design opportunities possible to help make vehicles on and off the road safer and more efficient.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: