Making Hydraulics Cool Again to Attract the Next Generation of Engineers

Key Highlights

- Internships offering the opportunity to participate in hands-on projects and leverage technical expertise provide a more robust educational experience.

- Enabling interns to see how their technical knowledge can be applied to hydraulics can spark interest in a future career in the field.

- Investing in the education of the next generation of engineers benefits innovation within a company and the fluid power industry as a whole.

It’s a challenge faced by most manufacturers today — how to create an internship program that provides students with meaningful, interesting work that actually delivers value to the company.

Parker Hannifin’s Hydraulic Valve Systems Division within the Motion Systems Group appears to have discovered the answer with the internship program it created, and many other divisions at the company are following the same template to reap similar rewards.

Creating a Model Internship Program Through Hands-On Projects and Mentoring

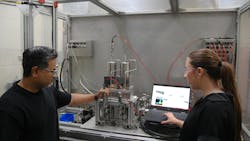

Over the past few years, the Hydraulic Valve Systems Division at Parker has developed internship positions on the Advanced Engineering, Simulation and Manufacturing Team that merge the skills of engineering students with the needs of real projects.

“Parker is not unique in the challenges faced in creating meaningful internship positions where students can apply their newly acquired classroom skills in a real industrial setting,” said Bipin Kashid, an engineering manager and chief engineer at Parker. “It’s hard to identify worthwhile projects that can be completed within the short duration of a summer or semester program.

“And it’s even harder to identify work that will get the interns excited about what they are doing, especially considering that most of the students we see today don’t have much, if any, real hands-on experience with hydraulics. That’s because hydraulics is typically not a part of the standard engineering curriculum at most schools,” he said. “So, their first impression can be that hydraulics isn’t very exciting, which may lessen enthusiasm for pursuing it as a career. But well-designed, hands-on projects and mentoring often reveal the field’s creativity and technical depth and inspire many students to consider returning to Parker after graduation.”

According to Kashid, the trick was in making hydraulics cool again so that the students could be excited about what they were doing and realize the true value of their work.

“We saw a major improvement in intern attitudes and motivation once we met them at their level where they already excelled,” added Kashid. “And that sweet spot turned out to be technology. These young people have a natural affinity for computers and coding, and we’ve found that they can quickly absorb the workflow being done by our more seasoned engineers and develop software programs that reduce what used to take hours or days for completion down to a few minutes.”

What Kashid and others involved in Parker’s internship training programs realized once they started providing more hands-on opportunities is that these interns bring valuable coding abilities that they can apply to create tools that automate many of the complex simulation workflows Parker’s engineering teams handle daily.

Leveraging the technology expertise of these interns not only enhanced productivity, but it also provided the interns with valuable hands-on experience that prepares them for future engineering challenges that they’ll face as the engineers of tomorrow.

How an Intern’s Simulation Expertise Improved Engineering Workflows

Simulation software has become an increasingly vital tool for engineers. It enables virtual testing, reduces prototyping costs, shortens product development timelines, and improves overall quality. However, these powerful tools come with their own set of challenges, including a steep learning curve for engineers from previous generations to master the software and obtain meaningful results. There is also a significant time investment required to set up and run simulations.

Recognizing these challenges, a recent Parker summer intern — Courtenay Mackey from Case Western Reserve University in Cleveland — took on the task of developing solutions that streamline the simulation process and make the software more accessible.

Mackey’s primary focus was creating automation scripts that streamlined and eliminated many of the repetitive, time-consuming steps involved in performing Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations. Both of these processes are critical for understanding potential failures, resolving warranty claims, and reducing the prototyping costs of many of the division’s products.

By leveraging IronPython, an integrated scripting language within Ansys software, Mackey was able to write custom scripts that interact directly with Ansys simulation environments. This approach not only accelerates the setup and execution of complex simulations but also reduces the potential for human error, allowing engineers to focus more on interpreting results and optimizing designs.

“This was just one example of a Parker Hydraulic Valve Systems internship that provided a student an opportunity to solve real problems with real impact,” said Kashid. “She wasn’t just learning basic software and duplicating previous workflows; she created tools that our engineers with decades of more experience actually use. As a bonus, the takeaway for her was that Parker really does cool stuff and is an exciting place to work.”

Exposure to Multiple Departments Enhances Learning for Next-Generation Engineers

The Hydraulic Valve Systems team was so impressed with the final product that they encouraged Mackey to present her work to various divisions across Parker’s diverse industries. This cross-division experience not only showcased the efforts of the Hydraulic Valve Systems simulation team in automating and streamlining complex workflows but also introduced the intern to the wide range of unique business areas within Parker, including Gas Turbine, Motion Technology Center, and Fluid Systems, among others.

Engaging with multiple Parker locations allows interns to gain a broader perspective on how different teams and divisions operate, fostering a deeper understanding of the company’s overall structure and strategic goals. This exposure enriches the learning experience, helping interns grasp the complexities of real-world engineering challenges and better prepare them for future careers in the engineering field.

The focus at Parker is on building a culture of collaboration, and this extends to interns, as well as new engineering hires. Interns are embedded into existing engineering teams and assigned to active projects in new product development, sustaining engineering, and engineering digitalization. They get an opportunity to work closely not only with engineering teams but also with cross-functional groups, such as manufacturing, IT and supply chain.

"I joined Parker as an intern/co‑op in summer 2025 on the Advanced Engineering team, building immersive AR/VR (augmented reality/virtual reality) tools while developing transient CFD models, lab‑validation tests, and simulation‑automation workflows for valves. Hydraulics was new to me, but hands‑on projects and cross‑division collaboration with engineers across Parker teams rapidly brought me up to speed,” said Jenna Watts, a former Parker intern now employed as a full-time engineer at Parker.

“The automation tools I created reduced simulation setup time and delivered real business value, and that experience helped me transition into a full‑time engineering role where I now apply modeling, simulation, and automation to accelerate product development and validation," she said.

Holistic Educational Experiences Create a Win-Win Situation for Interns and Companies Alike

Parker Hannifin’s internship program stands out not only for providing meaningful, impactful projects but also for fostering cross-divisional engagement that broadens interns’ understanding of engineering in a real-world industrial context. By exposing interns to the diverse facets of Parker’s operations, the program cultivates a comprehensive perspective on how engineering solutions drive innovation across industries from aerospace to off-highway machines to climate control. This holistic experience empowers interns to contribute valuable work that benefits both their personal development and the company’s ongoing success.

Moreover, programs like these play a crucial role in encouraging talented students to return post-graduation, often participating in Parker’s Engineering Leadership Development (ELDP) Program. The highly structured and competitive program is designed to train future leaders in the company’s various engineering disciplines. The program typically lasts between 1-2 years and involves multiple rotational assignments through which new engineers gain hands-on experience and a broader perspective of the company’s operations. They are also equipped with cutting-edge tools and connected with industry veterans.

“The Parker Engineering Internship and Co-op program delivers hands-on experience that prepares emerging engineers for immediate impact, so many return as full-time team members,” said Shawn Horner, vice president of technology and innovation at Parker’s Motion Systems Group. “In addition to our Engineering Leadership Development Program accelerating career growth and building future leaders, initiatives like this form a strong talent pipeline that brings fresh skills, cross generational learning, and continuous innovation.”

Within the Hydraulic Valve Systems division, the focus is on learning hydraulics and how advanced software programs are keeping hydraulic systems relevant and competitive. Other advanced engineering projects often supported by interns include simulation workflow automation, engineering process automation, and robotics. Through this cycle of learning, Parker continues to build a strong pipeline of skilled engineers.

“I joined Parker’s Hydraulic Valve Systems division as a design engineering intern in summer 2021 writing to help modernize legacy processes. During that time, the division was implementing its first robot cell, and I was invited back for a spring internship to finish that project. After graduating in 2024 I was hired full time as a manufacturing engineer,” said George Rak, a current Parker engineer who started at the company as a summer intern.

“This role has helped me grow both technically and professionally. I am grateful the Parker team trusted an intern with high‑impact projects. Because of that trust, I’m now pursuing my passion for automation as my profession,” he said.

The Importance of Investing in the Engineers of Tomorrow

In a world where engineering is rapidly evolving, Parker Hannifin’s internship program is more than just a summer job; it’s a strategic initiative to grow the next wave of talent, invest in tomorrow’s breakthroughs and stay at the forefront of innovation. By connecting students’ natural strengths in coding, systems thinking, and problem-solving with real-world engineering challenges, Parker is shaping engineers who are ready to innovate, lead, and make an impact.

“More than anything, I think the success of our integrated, hands-on internship programs demonstrates that we can all learn something new, no matter how long we’ve been on the job, and these up-and-coming engineers definitely have skills and knowledge that can make an immediate impact, even if they don’t yet know how a pump or valve works. There is true benefit in enabling generations to learn from each other,” said Kashid.

For young engineers, Parker’s hydraulics program offers not just experience but a launchpad. It’s a place where their contributions matter and where they become part of a larger mission — the Parker Purpose of Enabling Engineering Breakthroughs That Lead to a Better Tomorrow.

This article was written and contributed by Parker Hannifin.