Electrification Trends: The Rising Popularity of Hybrid Systems

Key Highlights

- Hybrid systems are growing in popularity due to the many benefits they can provide various mobile machinery applications.

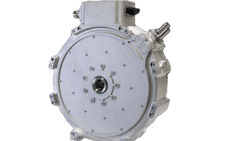

- Axial flux motors are aiding uptake of hybrid systems by providing a powerful electric motor option that easily fits into existing powertrain spaces.

- The need for quieter, emissions-free operation is driving use of hybrid systems in marine, construction and other applications.

Electrification continues to grow in construction, agriculture, mining and other mobile equipment industries. A reduced reliance on fossil fuels, lower maintenance as well as enhanced performance are among the many drivers for the uptake of electric-powered machines.

While full-electric solutions exist, particularly for compact machines, hybrid systems are the preferred route for many, especially larger machines which remain difficult to electrify due in part to the battery power required — adding weight and cost to a machine.

Hybrid systems are typically a more feasible option for larger machines as they commonly pair electric motors and other components with diesel engines, making it possible to achieve some of the benefits associated with electrification while maintaining the power and run time of a traditional engine-powered machine.

According to Steve Hornyak, CEO, Turntide Technologies — a developer of electrification solutions — hybrid systems are growing in popularity in many mobile equipment applications due to the various benefits they can offer.

Power & Motion spoke with Hornyak about these benefits, the applications in which hybrid systems are being employed as well as the continued growth he anticipates for these systems in 2026 and beyond.

*Editor’s Note: Questions and responses have been edited for clarity.

Power & Motion: What is the state of electrification today? Are you still seeing demand for electrification, or has it cooled some over the past year? Are there applications where you are seeing more demand for electrification compared to others?

Steve Hornyak: Fully electric systems are still a goal, but hybrid systems are more than a step in the electrification process. Hybrid systems are a solution not just a stopgap. For some vehicles and equipment that need high power for heavy jobs, long range, or both, quiet operation and lower emissions, hybrid systems may be the only solution. I’ve seen the hybrid trend growing throughout 2025 and expect this to continue into 2026.

Another trend we are seeing is a desire to have an integrated, systems approach to the design process. Being able to go to one partner for the drivetrain components is a huge win, especially when the company helps pair the motor and inverter, which can be a time-consuming and complicated process. We are proud to be able to provide this type of approach. This is partly possible because of our Turntide Turnkey Solutions partners that help fill any gaps that an OEM may have.

Power & Motion: What are some of the trends you see shaping the electrification industry today?

Steve Hornyak: Hybrid and systems approaches. We are working with OEMs every day to determine what components and systems are ideal for their applications, and many of these are hybrid and not fully electric.

In these hybrid systems, the flat profile and high torque density of axial flux motors are a game changer. They easily fit in most existing powertrain spaces and provide more torque than much larger radial flux motors.

Power & Motion: What role are you seeing hybridization play and what makes it a good option for some customers and/or applications?

Steve Hornyak: Hybrid systems are becoming preferred in many verticals and applications when compared to fully electric systems.

Quiet operation, range and charging infrastructure, and emissions requirements are the main reasons that hybrid systems are growing in popularity. In demolition and construction equipment, for example, operation in rural areas can be carried out with diesel. However, in urban areas where noise ordinances [exist] or indoor [machine use] is required, electric operation is used.

Another vertical in which hybrid operation is preferred is marine. Some ports and residential areas require quiet, emissions-free operation [which hybrid systems enable].

Power & Motion: How are you seeing hybrid systems being applied, and what are some of the technologies involved?

Steve Hornyak: Axial flux motors are a game changer for hybrid systems. Their slim profile makes them ideal because, for most applications, they can be added to the existing powertrain footprint without altering the design. For equipment currently in production that an OEM would like to convert to hybrid, this makes the process simpler.

An electric axial flux motor provides the torque and power required in most verticals to drive traction, hydraulics, or other [machine] movement or operation. It also can be used as a charger for the battery during hydrocarbon operation and braking.

Power & Motion: How do you see hybridization and full-electrification trends progressing in 2026?

Steve Hornyak: We are seeing hybrid [being the trend] in most of our verticals, with the exception of mini construction equipment. We are working with OEMs in the marine, industrial, construction, commercial vehicle, and premium automotive verticals.

Hybrid systems provide OEMs with the best of both worlds, providing decreased emissions without range anxiety or power and torque concerns. They have potential in just about every vertical from construction and material handling to marine and recreation.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: