How Thermal Expansion Data Improves Motion System Component Design

Precision is the cornerstone of motion system engineering. Whether in robotics, aerospace, semiconductor manufacturing, or high-speed automation, even micron-level deviations can degrade performance or lead to component failure.

One often underestimated factor in this equation is thermal expansion. As components heat and cool during operation or environmental exposure, their dimensions change. Understanding these changes — quantified by thermal expansion data — is vital to ensuring long-term accuracy, repeatability, and reliability.

Why Thermal Expansion Matters in Motion Systems

Motion systems depend on the precise coordination of linear and rotary movements across mechanical, electronic, and software domains. As temperatures fluctuate, materials expand or contract, potentially altering the dimensions of critical parts such as shafts, guide rails, lead screws, and housings. If these thermal shifts aren't accounted for in design, issues such as misalignment, jamming, or positional drift can occur.

For example, an actuator with a ball screw and linear guide operating in a controlled environment may still experience temperature changes of 50–86 F during a duty cycle. A steel screw 39.37 in. long could expand by over 0.014 in. — enough to impact alignment and backlash tolerances.

Thermal expansion data, specifically the coefficient of thermal expansion (CTE), helps predict these changes accurately. When integrated into design workflows, this data ensures engineers can model how systems will behave across expected thermal loads and incorporate mitigation strategies where necessary.

Key applications where thermal expansion data is critical include:

- Precision Positioning Systems: Applications like wafer steppers, coordinate measuring machines, and laser cutters require positional accuracy within microns. Any thermal deformation in the guideways or support structures directly affects measurement fidelity or cutting precision.

- High-Speed Automation: Rapid movements generate internal heat through friction and electric drive losses. The expansion of bearings, mounts, and interfaces must be accounted for to avoid cumulative tolerance stack-up.

- Aerospace and Satellite Mechanisms: Thermal cycling in orbit can be extreme. Antenna actuators, solar panel deployers, and gimbal systems must maintain accuracy despite severe thermal gradients.

- Injection Molding and Additive Manufacturing: In tooling and gantry-based 3D printers, frame expansion can alter dimensional outputs or layer misalignment during long print cycles.

In each of these applications, thermal behavior influences not only geometric integrity but also wear patterns, preload forces, and sensor accuracy.

Read more about the effects temperature can have on hydraulic system performance.

Measuring Thermal Expansion: Analytical Tools and Techniques

To generate meaningful design inputs, engineers must rely on accurate thermal characterization.

This is where instruments such as dilatometers become essential. Dilatometers directly measure dimensional changes in a material as a function of temperature, providing precise thermal expansion curves. These tools enable engineers to determine the CTE under relevant thermal conditions, making them indispensable in the design of precision motion components.

For comprehensive analysis, dilatometry may be complemented by thermomechanical analysis (TMA), which evaluates deformation under load. When used together, these tools help engineers develop a complete picture of how materials will behave in thermally dynamic environments.

Although techniques like thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) — typically used in a simultaneous thermal analyzer (STA) — do not measure expansion directly, they offer valuable insights into complementary thermal behaviors such as melting, degradation, and phase transitions. These data can support broader thermal modeling efforts, especially in polymer and composite applications.

By integrating data from dilatometry with other thermal analysis tools, engineers can define safe operating windows and predict system performance with greater fidelity.

Integrating Thermal Expansion Data Into Component Design

Designing motion systems with thermal expansion in mind requires a multi-tiered approach.

1. Material Selection

Every material has a unique CTE. For example:

- Aluminum alloys: ~12.8 µin/in· F

- Steel: ~6.7 µin/in· F

- Titanium: ~4.7 µin/in· F

- Invar: ~0.67 µin/in· F

- Engineering plastics: can exceed ~39 µin/in· F

Selecting materials with matching or compensating CTE values for mating parts helps reduce stress and misalignment during thermal cycles. In high-precision builds, low-CTE materials like Invar or carbon fiber composites are often used in critical structural members to stabilize geometry.

2. Thermal Modeling in CAD and FEA Tools

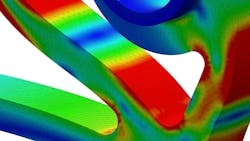

Modern design environments allow engineers to simulate thermal deformation using finite element analysis (FEA). By inputting accurate CTEs and applying realistic boundary conditions, teams can visualize expansion and contraction under dynamic thermal loads. These simulations guide dimensioning decisions, gap allowances, and fastener placements.

3. Dimensional Compensation

Where deformation is unavoidable, motion systems can incorporate compensation mechanisms:

- flexible couplings or expansion joints

- preloaded bearings that tolerate axial shifts

- precision sensors (e.g., laser encoders) with thermal compensation algorithms

- software-based positional offsets in closed-loop systems.

In some cases, designers apply deliberate over-dimensioning at room temperature so that components settle into nominal dimensions under normal operating heat.

4. Assembly and Tolerance Planning

Accounting for thermal expansion during assembly prevents stress concentrations and premature wear. Differential expansion between bolts and housings, or between guide rails and machine bases, can create significant forces. Bolted joints may loosen, or interference fits may become overly tight or slack.

Specifying appropriate tolerances, clearances, and torque values — especially where dissimilar materials meet — improves reliability and simplifies maintenance over the system’s life.

The Role of Technicians in Thermal-Aware Installations

While much of the precision engineering happens during design, field technicians play a key role in realizing thermal-aware systems. Proper installation practices ensure that the thermal behavior anticipated during design is preserved in reality.

Technicians should:

- Avoid assembling components in temperature extremes.

- Allow parts to thermally stabilize before measurement or alignment.

- Use calibrated instruments with compensation for ambient variation.

- Inspect thermal relief features like slots, bellows, or floating mounts for correct function.

Technicians are also often responsible for monitoring systems over time. If thermal drift is detected in encoders or sensors, feedback to engineering can drive design iterations or material changes.

Toward Smarter, Thermally Resilient Systems

The integration of thermal expansion data is part of a broader trend toward thermally resilient design. As motion systems grow in complexity, size, and duty cycle intensity, ignoring temperature effects is no longer an option. New developments in materials science, real-time sensor feedback, and smart compensation software are making it easier to account for thermal behavior from concept through operation.

Machine learning models can even use historical thermal data to predict future drift or component fatigue, enabling predictive maintenance. Meanwhile, access to high-resolution data from tools like dilatometers and modern TMAs empowers materials engineers to qualify custom alloys or composites for demanding applications.

Thermal expansion data plays a critical role in the design and performance of motion system components. By understanding how materials respond to temperature changes, engineers, designers, and technicians can build systems that remain precise, reliable, and robust under real-world conditions.

From selecting materials with favorable CTEs to modeling thermal loads and implementing compensation mechanisms, every decision informed by accurate thermal data contributes to system longevity and accuracy.

Precision motion systems must account for the physical realities of operation, including heat. Integrating thermal behavior early in the design process is essential for excellence.

This article was written and contributed by Vincent Linseis, Managing Director and Co-owner of Linseis Thermal Analysis.

About the Author

Vincent Linseis

Managing Director and Co-Owner, Linseis Thermal Analysis

Vincent Linseis is Managing Director and Co-Owner of Linseis Thermal Analysis, manufacturer of instruments for material analysis in research and quality control. He establishes the third Linseis generation’s authority in the business, playing a key role in driving the company’s digital transformation and spearheading the technical development of its precision measuring instruments.

Leaders relevant to this article: