The IoT Intends to Revolutionize Hydraulics and Pneumatics

In those dark factories in the late 1800s, the sweat of our great grandparents mixed with the steam of early manufacturing. The steam engine worked alongside the man in mechanically aided production. That was Industry 1.0.

Our grandparents lay mortar on the stone of their parents, with electricity and the assembly line. Their burden was not as heavy with division of labor, but it was specific and skilled. Course machinery whirred tirelessly, absorbing amperage, while pouring out heat and product. That was the early 1900s.

In the 1970s, our mothers and fathers, as well as we, sat in a brightly lit computer-controlled wonder. Computer Numeric Control (CNC) changed how everything was made overnight. Almost all machine operations are automatic. Repetition is high, skilled machinists rare, but it’s the evolution of how we build things. Dubbed Industry 3.0, it was the introduction of computing in the factory, and has been that way up to today, 2015.

What’s next might remove people from the factory altogether, though.

General Electric calls it “The Industrial Internet.” The Smart Manufacturing Leadership Coalition (SMLC) has another name: “Smart Manufacturing.” SMLC, prominent in the U.S., hopes to promote the adaption of “Manufacturing Intelligence.”

“Industry 4.0” is already here, a term coined by the German Government in 2011-12 (called “Industrie 4.0”). Although this term was the product of a contracted “think tank,” it’s a good phrase to describe the manufacturing world of the next generation. What else could it mean, but the incorporation of the Internet and all of its fruit?

Within Industry 4.0, smart factories consist of three branches:

• The Internet of Services, aka the cloud: It is a deliverer of services. It shares resources such as applications, content, databases, records, storage, computing power, and networks among all those who are connected.

• Cyber-physical systems: These represent the connectivity between digital and physical. Embedded systems, e.g. smartphones with all of their sensors and connectivity, fall under this category.

• The Internet of Things (IoT): Here, connected devices use the Internet without human influence. This is potentially the most important and active component of the branches. Imagine a CNC machining center, when predicting a possible failure, autonomously corrects itself and then sends alerts to those who need to know.

Hydraulics and Pneumatics in Industry 4.0

Like all aspects of manufacturing, the ubiquitous, often invisible, hydraulics and pneumatics technologies benefit from Industry 4.0 standards. The step to integrate those standards and move beyond 3.0 has already been underway with European and U.S. manufacturers. For instance, Illinois-based tech company Bimba adopted the Intellisense platform to drive its pneumatic components (Fig. 1).

Intellisense incorporates sensors, cylinders, and software that enhance productivity through the use of real-time data, providing feedback on pneumatic wear and tear that can be utilized to maximize efficiency. It’s a prime example of how IoT is driving Industry 4.0 “intelligent” production systems that can communicate in real-time with detailed and “predictive” information on any particular part. As a result, users from any industry can shift their focus from emergency repair to preventative maintenance, reducing production downtime.

By sparking the fourth industrial revolution, the IoT must be adopted by virtually all industries in order for them to stay competitive in a fast-paced world. This is certainly true for hydraulic and pneumatic systems in manufacturing plants that rely on critical information to keep production at peak performance.

Connection to the IoT can relay a host of information, including operational data like energy consumption and function status, which can be accessed from anywhere. Not only would maintenance personnel receive that information, but others in the production chain (e.g. part manufacturers) could use the information to bolster their products for increased efficiency and lifespan.

This file type includes high resolution graphics and schematics when applicable.

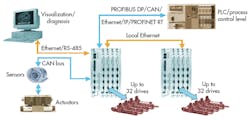

In a case study presented by the Rexroth Bosch Group (engineering firm in Germany), merging the physical world with the virtual highlights the importance of Industry 4.0 adoption in the hydraulics arena. The study cites that typical controllers for hydraulics come pre-programmed with software for transitioning from “path control” to “force control” in order to stay synchronous with one another in the production chain (Fig. 2). Industry 4.0 gives hydraulics a decentralized intelligence of sorts, allowing them to function autonomously and adapt to changing process parameters.

Bosch actually introduced intelligent hydraulics back in the 1990s with its electro-hydraulic linear axes, which featured decentralized intelligence. Now with upgrades to IoT-connected “smart” components occurring at such a rapid rate, industry leaders are calling for an Industry 4.0 standard in regards to communication protocols and languages. Machine manufacturers are already integrating Ethernet protocols (Ethernet-IP, PROFINET, etc.) into various products for easy integration into IoT networks, but so far, no set standard serves as a universal platform.

Where is Industry 4.0 headed?

Industry 4.0 is a great endeavor that manufacturers look to adopt even on the heels of those still clinging to the widely successful third Industrial Revolution. The typical train of thought is that the newest structural change will be the last, even though innovative and better systems have taken shape but never reached fruition. Instead, most tend to hold onto what’s tried and true.

So, where is Industry 4.0 heading, and will Industry 5.0 follow it in the near future in concert with evolving technology? Those questions are worth exploring if only to gain insight into what the future holds.

When steam power heralded in the first Industrial Revolution, manufacturers found a level of efficiency in production that had never witnessed before. The prevailing thought at the time was nothing could top the pinnacle of industry manufacturing—until the second revolution streamlined industry through the use of electrical energy and mass production. Certainly nothing could top that; then, along comes revolution number three and the computer age. Soon to arrive, of course, was the Internet, unleashing the fourth Industrial Revolution. It’s been adapted for use with robotic and automated supply chains, giving manufacturers an even greater level of efficiency with increased data collection.

Industry 4.0 has taken data acquisition and communication to heights that previously were thought to be impossible. Everyone from plant managers to maintenance workers have direct access to real-time data that only serves to change and enhance industry methodologies.

For example, Rockwell Automation, an intelligent industrial automation company, was tasked with installing 11 IoT connected machines into a new factory for King’s Hawaiian in Oakwood, Georgia. Upon completion, the popular bread company was able pump out an additional 180,000 pounds of bread than what was being produced in a similar but unconnected plant in Hawaii. The machines were connected to a software platform called FactoryTalk, which allows managers to view historical data alongside real-time information, providing a production-wide overview of plant operations. The result was faster time to market, workforce efficiency, and smarter cost expenditures.

There’s no doubt that Industry 4.0 has significant advantages over 3.0, but what does the future hold in terms of the next revolution? With the onset of new “smart materials” being developed by institutions such as MIT, materials that can change their properties and even self-repair, could conceivably change industry into a form we have yet to comprehend (Fig. 3).

Imagine hydraulics and pneumatics that could change their physical characteristics on demand, negating the need to upgrade to superior technology or reconfigure themselves for modified tasks. Consider that for a moment—would we recognize what industry manufacturing is in 50 years in terms of technology compared to what Industry 4.0 and the IoT offers today? Surely the “father of hydraulics,” Joseph Bramah (inventor of the power press), would consider the new Industrial Revolution as science fiction compared to his in the 18th century. We will likely feel the same…but when?

Cabe F. S. Atwell is a graduate electrical engineer actively plying his expertise in the industry and at his company, Gunhead. Contact him at [email protected].

References

• "Appetite for Improvement." Innovation Success Stories. Rockwell Automation.

• "Bimba Unveils "Smart" Technology Platform That Provides Predictive Intelligence for Pneumatics." Bimba. 30 Sept. 2014.

• Guberan, Christophe, and Erik Demaine. "Programmable Materials." Self-Assembly Lab.

• "IntelliSuite Product Overview." Intellisense.

• "News." Bosch Rexroth News. Bosch Rexroth.

About the Author

Leaders relevant to this article: