Pretty, precise plumbing

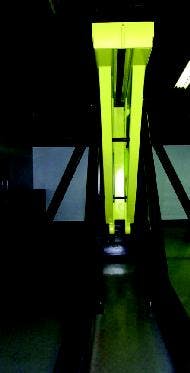

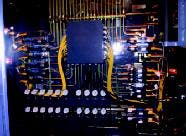

Dynamic cylinder test fixture at Servo Kinetics. Left: Clamp fixture control panel for Ann Arbor Machine's dial table.

Okay, you've gone over your bill of materials. You have everything you need: reservoir, pump, valves, hoses, tubing, filters, cylinders, fittings, and an assortment of accessories. Now you'd like to get the hydraulic system installed in an orderly fashion so it is easy to maintain, reliable, and looks good.

Accomplishing all this seems more art than science, so where do you turn? One solution is to solicit the services of a company specializing in custom design, layout, and installation of pipe, hose, and tubing assemblies. The Franklin Co., Swartz Creek, Mich., specializes in industrial piping — but their true claim to fame is precision tube bending for hydraulic, pneumatic, and lubrication systems. In early 2006, the company was asked by Servo Kinetics, Ann Arbor, Mich., to plumb the world's largest dynamic cylinder test machine.

The machine is used in full-load testing of precision motion actuators that operate commercial and military flight simulators. Franklin upgraded and piped several C-130 flight simulator training sites as well. This called for precise calculations, as most piping had to be done in under-the-floor trenches. The amount and size of the pipe or tubing become critical where 45° or 90° changes in direction are involved.

Precision tube bending is helpful in many applications, such as machine tool equipment, transfer lines and hydraulic power units. Some of the benefits include:

- ability to fit plumbing into compact spaces

- ease of maintenance proper component and fitting installation

- vibration-free systems, and

- neat appearance, which occurs when lines are plumb, level, non-interfering, and look like they're part of the plan.

For more information on precision tube bending, call Frank Bobo at (810) 655-3636 or e-mail [email protected]