CONEXPO-CON/AGG 2026, one of the largest construction industry events, is just a few short weeks away, taking place March 3-7 at the Las Vegas Convention Center.

Each edition of the triennial event provides a look at the latest equipment and technology launches for the construction industry. As this is an important customer segment for hydraulics, pneumatics and electromechanical technology suppliers, several are planning to showcase their latest developments at CONEXPO 2026.

We’ll be continuing to publish news about technology launches and other information relevant to CONEXPO 2026 leading up to the show and during it. So be sure to stay tuned for more updates, and sign up for our newsletters if you haven’t already so they can be delivered directly to your inbox — including a special newsletter that will be sent each day of the show.

Following are some of the technologies set to be displayed at this year’s show, demonstrating the innovations taking place in the industry.

Danfoss Highlighting Advancements in eHydraulics, Motors, Hoses and More

Danfoss Power Solutions plans to feature over 100 products at its CONEXPO 2026 booth, organized by the machine functions for which they are typically used — propel, steer, work and control.

To help demonstrate this, the company will have a display with two types of wheel loader system architectures, one a modern hydraulic-powered machine and the other an electric machine. A new steering simulator will also be at the Danfoss booth showcase its steering technologies.

New technologies the company plans to debut at this year’s show include the BMV Integrated Drive Motor, FC619C Corrugated Suction Hose, ICMB Industrial Cam Lobe Motor, and upcoming additions to the PVG Valve family.

According to Danfoss, eHydraulics featuring advanced control capabilities and the company’s PLUS+1 software will be a key topic area on display because of its growing use in construction and other mobile equipment applications. Danfoss ePump and eTraction systems will be among the technologies on display to showcase this trend. In addition, representatives from the company will present on this technology trend along with other topics during the National Fluid Power Association’s (NFPA) Advanced Hydraulics Conference being held during CONEXPO.

Enerpac Debuting New Hydraulic Tools, Lifting and Transportation Systems

Enerpac, a developer of high-pressure hydraulic tools, is planning to introduce several new technologies at CONEXPO 2026.

Appearing at CONEXPO for the first time will be:

- 600T capacity Enerpac SBL600 hydraulic gantry,

- 60T capacity DTA by Enerpac automated guided vehicle (AGV) Smart Transporter,

- 200T capacity SCJ-Series cube jacks,

- battery-powered SC-Series and XC2-Series pumps,

- PPH-Series joint pin puller and

- E-mover skate system.

The company will also launch its first Battery Powered Split Flow Pump and next generation, newly designed 400T capacity Low Height Skidding Systems (LH400). Enerpac will offer demonstrations of many of these new technologies as well to show attendees how they can be used in their own operations to help with moving and servicing items.

Moog Showcasing Adaptive Electrification Management System

Moog Inc. plans to show its latest development for electric vehicles, the Adaptive Electrification Management System (AEMS) at CONEXPO 2026. AEMS is a modular system designed to help OEMs more easily electrify and automate their machines.

It is comprised of several components contained in a compact package, including:

- a configurable controller,

- DC/DC converter,

- high-voltage distribution, and

- single- and dual-axis inverters.

The system features a high-voltage busbar and shared coolant manifold to help reduce the number of cables and hoses required, simplifying assembly and maintenance. It manages multiple electric vehicle functions simultaneously with streamlined software architecture to enhance performance and reduce power loss. Built-in diagnostics provide consistent system monitoring for traction, steering, lifting, and more across machine platforms, aiding implementation for machine developers.

AEMS can be adapted to machines of various sizes, from 6-ton compact track loaders to 25-ton excavators, allowing an OEM to deploy a single electrification and software platform across multiple lines, if desired, which helps to reduce development time and costs.

“AEMS reduces testing and configuration time by up to eight hours and supports over-the-air software updates post-production to add new features seamlessly,” said Dr. Nate Keller, Moog’s Strategic Business Manager, in the company’s press release announcing the system’s introduction at CONEXPO.

Per Moog, AEMs is already being utilized in some prototype machines and previous versions were used in the Bobcat T7X, CASE 580 EV fully electric backhoe and other construction machinery.

Rota Introducing New Position Sensor for Hydraulic Cylinders

Rota Ltd. will introduce its new ELU Series external sensor technology for hydraulic cylinders. Due to recent technology advancements, the sensor’s magnet is now up to 88% smaller than previous versions which helps to reduce costs, weight and installation space.

Designed to provide position sensing, the company’s external sensor technology propagates a magnetic field through a carbon steel cylinder wall, enabling accurate analog or digital position reporting for cylinders. This eliminates the need to use traditional installation methods such as deep drilling which may not be possible or economically viable in some applications.

The new ELU Series sensor can be used in a range of applications, including construction equipment, agricultural machinery, transportation and more.

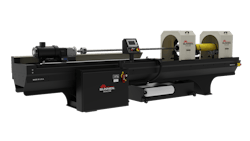

Sunnen Products Showing All-Electric Tube Honing

Sunnen Products Company — a developer of high-precision honing, bore sizing, and engine rebuilding equipment — will show its next-generation, all-electric tube honing solution for hydraulic cylinder repair and other industrial applications such as heavy equipment manufacturing.

The HTA Tube Hone features an all-electric drive to provide quieter operation as well as improved control and accuracy during bore reversals. It has a compact design to reduce floor space compared to traditional horizontal tube honing systems.

Features of the tube honing system include:

- Siemens Servo Stroker Motor with Belt Drive for smooth and precise operation

- spindle unit rated at 3 hp (2.24 kW) with adjustable stroker speeds from 5- 90 ft. per minute (1.5- 27.4 m per minute)

- robust power for resurfacing and repair tasks at spindle speeds of 20-300 RPM

- programmable auto tool feed system to aid efficiency and safety

- stroker joystick for precise tool positioning and stroke length adjustment

- load meter and universal V-block work holding system allow for real-time feedback and fast fixturing

- compatibility with ANR-275 tooling minimizes tooling changeover costs.

Trelleborg Exhibiting New Sealing Technologies for Off-Highway Equipment Applications

Trelleborg Sealing Solutions will show several of its seal technologies for use with hydraulic and powertrain systems in construction and other off-highway equipment applications.

Among these will be the company’s new Stefa Cassette seals which are designed for use in tractors, construction equipment and other heavy-duty vehicles. The seals feature multiple sealing lips integrated into them as well as a protective metal casing and an internal sleeve to create a robust barrier against contaminants while retaining lubricants.

This design helps to protect the seal and other machine components from mud, water and abrasive debris that typically destroys conventional seal designs noted Michael Cook, Global Segment Director Off-Highway, in the company’s press release announcing its presence at CONEXPO 2026.

Additional technologies on display include Trelleborg’s seals and wipers for use in hydraulic cylinders, it’s HMF17 FlatSeal flat gasket for preventing leaks in equipment, and its H2Pro range of sealing materials which includes a new rubber for use in high-pressure hydrogen environments.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: