Research Flexes Artificial Muscles for Energy-Saving Actuation

Researchers at Marquette University are investigating energy-saving system designs for low- to medium-pressure mobile hydraulic applications to reduce energy consumption and improve efficiency. Energy savings will be achieved through a combination of lightweight, powerful, flexible actuators known as hydraulic artificial muscles, as well as 3D-printing design methods to create lightweight, integrated systems, and energy-saving control techniques.

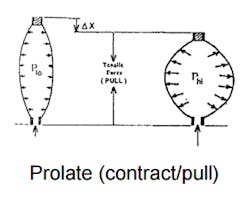

The research team, Dr. Mark Nagurka and Jonathon Slightam recently presented their work at the Industry/University Summit led by the Center for Compact and Efficient Fluid Power—an industry-university research organization dedicated to reducing the energy consumption in various industries through compact, energy-efficient fluid power systems. It places a primary focus on artificial muscles, which contract and pull to change output force. (See image below).

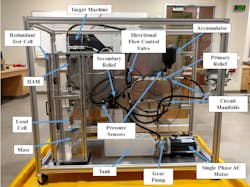

The team is developing improved models for hydraulic artificial muscles (HAM) to allow for improved designs that can be incorporated in model based control methods. Model validation and motion control experiments are being carried out on a hydraulic test bench, one of which is shown below. The researchers use hydraulics rather than compressed air to increase the specific power by using higher operating pressures. The team hopes to produce artificial muscle designs that are capable of operating pressures nearly double those achieved currently — going from roughly 1000 psi to 2000 psi — by using their improved models. This pressure rating would make them more suitable for small to medium off-road equipment.

The team uses software to optimize the topology of hydraulic machine structure that incorporates the artificial muscle, allowing for significantly reduced weight, increased compactness, and component integration, that will save energy for multiple applications. The researchers use 3D printing, to produce their complex weight-saving designs.

“Through our research, we hope to redefine the ‘state of the art’ for high specific-power actuation in the fluid power industry,” says research associate Jonathon Slightam. “We see the potential of these lightweight actuators to improve fuel economy and energy consumption in the fluid power applications industry-wide. Our work will help realize the commercialization of these actuators and better equip design engineers to consider artificial muscles and 3D-printing centric design techniques to develop energy-efficient mobile hydraulic applications.”

In continuing the research at MU, the team is improving actuator performance and specific power for industry and investigating novel applications. In their current project they plan to demonstrate the strength and energy-saving capabilities of the lightweight actuators in a compact robotic arm.

View the slides presented at the Industry/University Summit here.

About the Author

Leah Scully

Associate Content Producer

Leah Scully is a graduate of The College of New Jersey. She has a BS degree in Biomedical Engineering with a mechanical specialization. Leah is responsible for Hydraulics & Pneumatics’ news items and product galleries.

Leaders relevant to this article: