Lighter Cylinders Increase Design Possibilities

The demand for more compact, lighter, yet more powerful machines is unrelenting and requires continuous advancements in component designs and higher-strength materials. For in-plant machines, the higher pressures can often be accommodated by thicker-walled steel components. But this “luxury” is usually not an option for mobile equipment because components must be as small and lightweight as possible.

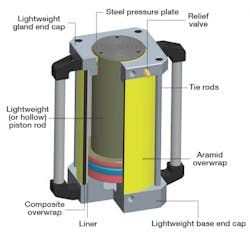

Basic configurations of Lightraulics composite cylinders (pictured on the left) include tie rod, top, and non-tie rod (round line).

To serve the demand for lighter, stronger components, Parker Hannifin Corp., Cleveland, began investigating alternative materials more than 20 years ago. According to Olaf Stelling, Ph.D., value stream manager for Parker’s Composites Technologies Europe Business Unit in Stuhr, Germany, depending on the level of weight efficiency of the original design, state-of-the-art lightweight components typically made extensive use of aluminum or titanium alloys. However, increasing the strength of metals typically reduces their ductility and, correspondingly, lowers fatigue life. Therefore, potential benefits for actuators made primarily of metal alloys are somewhat limited.

The latest result is ultra-lightweight hydraulic cylinders with barrels supported by carbon fiber reinforced plastics. Called Lightraulics, the cylinders are made from carbon fiber composites and lightweight alloys that are typically more than 60% lighter than the comparable steel cylinders. Stelling explains: “During the last decades, developments and products of composite materials moved into the focus as a reasonable alternative. Incorporation of fiber-reinforced plastics can overcome the conflict of reduced fatigue at higher strength. They offer dramatic weight savings potential, and exceptional burst and fatigue strengths.”

Not just a lightweight

Parker developed its Lightraulics composite cylinders by combining lightweight materials with unconventional designs and manufacturing techniques to make new equipment designs possible. On aerial lifts and work platforms, for example, lighter hydraulic cylinders means payloads can be increased or longer horizontal reach can be obtained. An additional benefit is corrosion resistance. Parker literature states that “the fiber as well as the resin material will not corrode. This leads to longer product life and cost savings on maintenance.”

The cutaway pictured on the left shows major features of Parker's Lightraulics jack, which can be carried without the need for lifting equipment.

Parker also states that “the strength-to-weight ratio of the composite cylinders is typically twice that of steel, and its stiffness is approximately 2.5 times higher.” Furthermore, fatigue performance is described as comparable to that of titanium, aluminum, and magnesium alloys. Fatigue life is rated 250,000 cycles at 380 bar (5,500 psi) and tested for 500,000 cycles at that pressure.

Configurations

Parker’s basic Lightraulics cylinder is the T Series, which uses tie-rod construction to accommodate working pressures to 380 bar (5,500 psi) and test pressure to 570 bar (8,250 psi). Standard bores range from 80 to 200 mm, with maximum strokes to 3,000 mm. The Lightraulics C Series uses non-tie rod (round line) construction and shares identical specifications but offers weight reduction of up to 65% that of standard steel cylinders.

A tool cylinder for portable lifting and jacking operations is is 65 to 70% lighter than its conventional steel counterparts, which normally allows a single person to position and move the cylinder without the aid of lifting equipment. It’s available in four capacities, from 150 to 400 tonnes and strokes to 300 mm. Maximum working pressure is 700 bar (10,150 psi), and it has an integral relief valve. Parker also offers a hollow-rod version with capacity to 400 tonnes and identical pressure rating.