Side loading is the most-common damage observed on master-cylinder field returns and can lead to premature product failure. In an effort to improve master-cylinder performance, several samples of existing and new designs were tested.

Under ideal conditions, particularly linear loading, it was shown that existing master-cylinder design is sufficient. However, subsequent testing under side loading showed that the current design is susceptible to damage. We found that the major cause of damage from side loading is the steel rod wearing against the aluminum cylinder bore. The wear patterns created in testing are quite similar to those observed on field returns. The design and testing of a nylon cap on the rod end showed that side-loading damage can be virtually eliminated. Implementing this solution will result in a product with a longer life.

Master cylinders are a common hydraulic component used in brake and clutch systems to generate hydraulic pressure from a nonhydraulic pressure source. The master cylinders tested in this experiment are generally used in a fail-safe brake system on forklift trucks. In such a system, brakes are spring applied and released by depressing the brake pedal.

A master cylinder for this application typically is comprised of a cast-aluminum body with a machined cylindrical bore and various ports, Figure 1. A piston assembly is inserted into the body and is actuated by applying compressive force to a steel push rod. Push-rod diameter, cylinder bore, and surface finish are critical for the piston to generate pressure without leaking. The master cylinder push rod is attached to the body via a washer and snap ring. The push rod is designed to allow deflection of ±5° from the main axis of the part. This allows for linkages and mounting configurations that are not colinear with the cylinder. When the push rod is not colinear with the cylinder bore, side loading, Figure 2, is generated.

The problem of side loading

Although most master cylinders are designed to permit some side loading, any side loading is detrimental to the life of the master cylinder. We frequently see evidence of side loading on returns from the field. These include wear on one side of the push rod, wear on one side of the cylinder bore, aluminum grit in the cylinder, excessive wear on the push rod washer, and seal failure. In fact, we observe side loading as a symptom in more than half of field returns. If you include seal failure and contamination — both symptomatic of side loading — then more than 80% of returned master cylinders are accounted for. Ultimately, the combined effects of side loading prevent the master cylinder from generating pressure or otherwise stop functioning.

Figure 3 typifies side-load damage found on returned master cylinders. The cylinder has been cut open to better see the damage, which includes severe scratching on the bore wall. The damage is localized on one side of the cylinder bore, indicating a side load. This ruins the machined finish on the inside bore of the master cylinder, which is necessary for the piston seal to work properly. Moreover, the wear leads to the release of small particles of aluminum into the system, further damaging the piston seal or other hydraulic components.

Experimental design

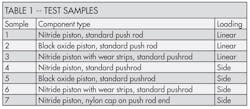

To find out how side loading affects the master cylinder, we designed a test apparatus, Figure 4, to simulate the life cycle of a master cylinder under linear and side loading. The experiment tested not only the current design of the master-cylinder components, but also several new designs intended to increase life.

Air pressure drives the pneumatic cylinder forward, stroking the test piece. The test piece is primed with DOT #5 brake fluid, which pressurizes the expansion cylinder on each stroke. The expansion cylinder’s purpose is to simulate the resistance that the system would normally see, and also to provide return pressure.

When the pneumatic cylinder (and test piece) is fully stroked, a relay cuts off pressure to the cylinder, allowing the pressure in the expansion cylinder and spring in the test piece to drive the actuator arm back. A counting instrument increases by one each time the actuator arm extends, thus recording the total number of strokes. The height of the test piece is controlled to induce colinear or side loading. When side loaded, the test pieces were subjected to an offset load of 5.7° to 0.7° beyond the upper specification limit for offset loading.

Test results

The samples were stroked varying amounts, depending on whether or when they failed, as well as time constraints. Samples 1, 2, and 3 were tested under ideal conditions (no side loading). None of these samples exhibited any seal, push rod, or bore wear, nor did they have any leaks after 20,000 strokes. No configuration was determined to be better than another. However, sample 2 lost about 40% of its black-oxide coating.

Samples 4 and 5 were subjected to side loading and did not have any design modifications to reduce side-loading damage. Consequently, both exhibited severe side-loading damage similar to that found on field returns. Figure 5 shows the bore damage to sample 4.

The significant bore wear is due to the push rod rubbing on the same area as a result of a repetitive side load. This damage causes aluminum grit from the bore wall to enter the system. Dimensional deformation causes the seal to not seal properly, resulting in brake fluid bypassing and leaking. Sample 5 exhibited similar damage.

Both samples showed that the action of the push rod wearing on the bore wall created the side-load damage. The steel push rod, significantly harder than the aluminum, made it the largest contributing factor to the wear observed.

Samples 6 and 7 had modified designs to eliminate the damage to the bore wall from the push rod. Sample 6 was tested using a push rod with a polytetrafluoroethylene (PTFE) cap on its end, applied by using PTFE heat-shrink tubing to the end of the push rod. The resulting cap was 0.015-in. thick. This sample was inspected after 10,000 strokes, at which point the PTFE cap had split into two pieces, and fine aluminum grit was present in the system.

The cylinder bore showed evidence of side-loading wear, although it appeared that the PTFE cap delayed the onset of bore wear. Sample 8 was tested with a machined nylon 6/6 cap on the push rod end. Because the nylon cap is significantly thicker than the PTFE cap, the push rod was turned down so that no dimensional interferences occurred with all the other components current design.

This sample was run for 30,311 strokes and then inspected. Minimal wear occurred to the nylon cap, there was no aluminum grit present in the system, and the cylinder bore showed little to no wear. The nylon cap proved very effective in eliminating side-loading damage and preventing aluminum particles from contaminating the system.

Conclusion

Side loading is the most common damage observed on master-cylinder field returns and can lead to premature product failure. In an effort to improve the master-cylinder product, several samples of existing and new designs were tested.

Under ideal conditions — particularly linear loading — the existing master-cylinder design is sufficient. However, subsequent testing under side loading revealed that the current design is susceptible to damage. We found that the major cause of side-loading damage is from the steel push rod wearing on the aluminum cylinder bore.

The wear patterns created in testing are quite similar to those observed on field returns. The design and testing of a nylon cap on the rod end showed that side-loading damage essentially can be eliminated. Implementing this solution will result in a superior product with a longer life.

Bill O'Rourke is General Manager and Co-owner of Jet Products LLC, Lexington, KY. For more information, call him at (630) 605-5944, email [email protected], or visit www.jetproductsllc.com.

Jet Products LLC manufactures custom engineered small hydraulic cylinders, master cylinders, hydraulic hose reels and brake products — all made in the USA. In early 2013, the company completed a substantial expansion of its production capacity and moved its headquarters and product development to Lexington, KY earlier this year.

About the Author

Leaders relevant to this article: