Rodless air cylinders take on tedious and dangerous tasks

Automated Systems & Equipment, Inc., a custom machinery builder in Spartanburg, S.C., finds that pneumatic linear actuators provide a competitive edge for them over electric motors with rack-and-pinion drives on conveyor systems. They used rodless cylinders extensively in two transfer station installations that automate the loading and unloading of pet food cans into baskets that go into retort ovens where the contents are both cooked and sterilized. The ovens use steam pressurized to 40 psi for this process.The automated system achieves three main goals:

• prevention of injuries to workers by eliminating the need to move heavy can-filled baskets manually

• assurance of product uniformity by maintaining a set time for the product to be in the oven, and

• productivity improvement. This system takes only one minute to load or unload five baskets into or out of an oven.

Two 50-mm diameter, guided rodless cylinders assist in the loading of cans into baskets. These 51-in. stroke units are mounted parallel to each other in a horizontal position and power a sweep arm that moves a layer of cans into the basket. A stainless steel divider sheet is placed between each layer by an assembly of vacuum devices positioned by a similar rodless cylinder with a 58-in. stroke. All the pneumatic assemblies are duplicated on the unloading station nearby.Vertically mounted hydraulic cylinders index floating bottoms in the baskets that raise or lower the product to assist in loading and unloading.

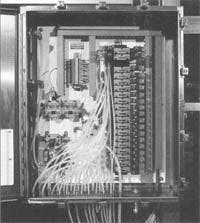

A stack of 19 directional control valves with manifolding sub-bases controls the system’s cylinders and also the set of grippers that hold the divider sheets during transfer. One valve controls air supply to the rodless cylinder moving the divider sheets; its high flow capability allowing both cylinders to be operated simultaneously.

A solenoid pilot-operated poppet valve, piped in tandem with a smoothstart valve, controls the vacuum service. Air preparation is provided by FRL combination units with integral shut-off valves. The shut-off valve vents the system to atmosphere in the closed position, thereby complying with the OSHA Lockout/Tagout rule for the control of potentially hazardous energy. Filters are fitted with Δp indicators to direct maintenance personnel to the filters when element service is required.

David Via, design engineer with Automated Systems & Equipment, provided details on this installation. Norgren, Inc., Littleton, Colo., supplied the Lintra rodless cylinders, Nugget valves, Designer II air preparation equipment, and poppet valves that were used.