Hydraulics moves mountains. . . one scoop at a time

To the casual observer, excavators, loaders, and other construction equipment appear to operate about the same as they did three or even four decades ago. A closer look may reveal subtle changes that have occurred to equipment design over the years. However, these external clues betray the dramatic improvements that today’s equipment holds over its ancestors of yesteryear. This is evident in Komatsu’s new PC400LC-8 excavator.

The PC400 incorporates a closed center hydraulic system with pressure compensation and load sensing to match hydraulic pressure and flow to work demands — a feature Komatsu has dubbed HydrauMind. Ultimately, this feature boosts fuel economy without sacrificing speed, control, or power. In fact, operators can choose from two boom mode settings, five working modes, and even boost maximum power by 7% for up to 8 sec for difficult digging projects.

The PC400LC-8 is powered by a Komatsu diesel engine that develops up to 345 hp at the flywheel at 1900 rpm. This power is transmitted to hydraulic pumps for hydrostatic travel drives, a swing drive, and, of course, implements. Maximum hydraulic flow is 182 gpm, and maximum operating pressure is 5400 psig for implement and travel circuits. A variable-displacement, axial-piston pump powers the main hydraulic system, and auxiliary pumps power boom, arm, and bucket cylinders, travel circuits, and a swing drive.

Mechanical power for the swing drive is transmitted to a planetary gear box that reduces speed and increases torque from an axial-piston motor incorporating a brake. The swing drive accommodates torque to 111,059 lb-ft at speeds to 9 rpm from a maximum system operating pressure of 4050 psig. The swing drive operates from its own 4.3-gal reservoir.

Power from hydraulics

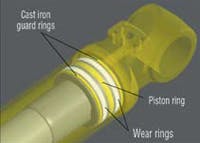

Four hydraulic cylinders arm the PC400LC-8 with plenty of power for digging. Each of two boom cylinders has a 6.3- in. bore, 61.8-in. stroke, and 4.3-in. rod diameter. The arm cylinder has a 7.3-in. bore, 71.7-in. stroke, and 4.7-in. rod diameter. The bucket cylinder has a 6.3-in. borte, 50-in. stroke, and 4.3-in. rod. All cylinders are equipped with metal guard rings that extend the life of piston seals by reducing pressure spikes transmitted to them from load-induced mechanical shock. By protecting the piston rings, the guard rings prevent drift in each cylinder.

An extra return hose is provided for the arm cylinder to make extension motion smoother by allowing a portion of the hydraulic fluid to return directly to tank. Furthermore, hydraulic hose and tubing assemblies use O-ring face seal fittings for leak-free operation.

Filtration boosts longevity

To ensure long, reliable operation, the PC400LC-8 incorporates filters on all return lines but also has 10- μm filters on the discharge lines of pumps. This augmented filtration provides extra protection for valves and other downstream components from contamination. As result, hydraulic fluid life has been extended to 5000 hr of operation.