bauma 2022: New Construction and Mining Technology Launches

*Editor's Note: This article was originally published July 15 and updated September 12 with additional information.

bauma 2022 is set to bring together a wide range of companies and technologies from the global construction and mining industries. OEMs and component suppliers alike plan to exhibit an array of products, new and old, which will benefit those working in construction and mining.

Hydraulic, electronic and other component manufacturers will be well represented at the triennial event as these are important segments in which they work. Danfoss Power Solutions, for instance, posted on LinkedIn it plans to exhibit solutions related to electrification, automation and digitization during bauma.

These are among some of the key industry trends impacting how component suppliers and OEMs are designing their products as they are becoming ever more present in the construction, mining and other heavy equipment industries. Organizers of bauma recognize this, and as such have noted them among the key topics under which the event will be organized:

- Construction methods and materials of tomorrow

- The way to autonomous machines

- Mining – sustainable, efficient, reliable

- Digital construction site

- The way to Zero Emission

READ MORE: bauma 2022 to Highlight Key Technology Trends for Construction and Mining Equipment

Several companies have begun announcing the products they intend to exhibit during the event which include new electrification solutions, machines offering improved performance and more, all of which provides a look at where the construction and mining equipment industries are today and headed in the future.

Walvoil Exhibiting Update to Adaptive Load Sensing Technology

At bauma 2022, Walvoil, part of the Interpump Group, plans to showcase an updated version of its Adaptive Load Sensing (ALS) technology. The ALS helps to reduce energy use through the use of software and electronic control for hydraulic pumps and valves.

Also on display will be the new EPX Series of directional control valves which use meter out compensation technology to recover wasted energy. This energy can then be reused to help improve system efficiency.

The two technologies can be used together to achieve up to a 20% reduction in energy consumption, benefiting overall efficiency for machinery into which these hydraulic system technologies are integrated.

View our media gallery to learn more about the ALS and EPX technologies.

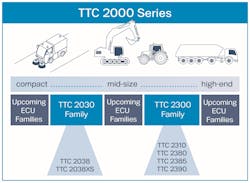

TTControl Introducing New ECU

TTControl plans to expand its family of TTC 2000 Series ECUs (electronic control units) with the introduction of the TTC 2030. This family of ECUs provide different size options but with the same modular building blocks, making it easier for OEMs to customize and quickly bring to market their new machine designs.

The new TTC 2030 features a large internal memory to aid with automation and operator assistance systems which OEMs are integrating into their machines. The ECU also enables transmission of sensor data via CAN, Ethernet and SENT (Single Edge Nibble Transmission) communication interfaces, providing greater flexibility for customers.

"The construction equipment industry is greatly increasing automation and efficiency for its customers," said Arno Purkrabek, Team Leader Product Management at TTControl, in the company's press release announcing the launch of the new ECU at bauma. "Only with the highest performance and a large set of interfaces, including high-speed Ethernet communication, can this transformation be successful. The software reuse, scalability and modularity supported by the TTC 2000 Series help machine builders meet these challenges in the most efficient way."

Safety standards for the construction, agriculture and automotive industries were followed during development of the TTC 2030 to ensure safe performance and minimize certification costs for OEMs.

Liebherr Components to Highlight Hydraulics, Digitization and Other Advanced Technologies

The components division of heavy equipment manufacturer Liebherr intends to exhibit a variety of products, many of which will showcase advancements in digitization and alternative energy.

Among the digital technologies on display will be Liebherr Components' camera monitor and surround vision systems which use sensors and software to improve visibility around machinery. An integrated digital wear measurement system will also be exhibited for the monitoring of slewing bearings, known as Bearing Clearance Monitoring (BCM). A force measurement sensor for hydraulic cylinders will be on display as well.

The BCM is able to measure bearing wear in axial and radial directions as well as tilting clearance said Liebherr Components in a press release about the technology. "A distinct disadvantage of all common wear measurement methods is the necessity for service technicians to mount dial gauges or other measuring devices directly on the slewing bearing in the danger zone under the excavator or other machines," explained Wolfram Halder, product manager of the slewing bearings business unit in the Liebherr Components' press release. "The Liebherr BCM system makes this unnecessary, as the measuring devices are already permanently installed on the bearing."

In addition, the BCM eliminates reliance on external service providers to measure bearing clearance as a sensor is integrated into the bearing which communicates to a gateway where the data is stored and accessible via an app by machine owners.

On the hydraulics side of things, the company has introduced a new online configurator which provides 3D models of the company's various hydraulic cylinders to aid OEMs in choosing the right cylinder for their application. Hybrid cylinders made from composite fiber are to be on display, demonstrating solutions which can provide a lightweight option to aid reductions in fuel use for machines.

READ MORE: Lightweight Hydraulics Offer New Opportunities to Manufacturers

Liebherr Components plans to exhibit its range of axial piston pumps, the LH30VO series, which now includes a nominal size 100 pump as well as those in sizes 28, 45 and 85. This will provide additional options for OEM customers. A modular system of controllers is available for the pumps to help improve their performance and efficiency.

For alternative drive systems, the company has developed a hydrogen fueled engine with many common parts to its diesel versions. Hydrogen injection technology is also available from the company. It is also developing electric turbochargers to help optimize performance of hydrogen-powered equipment. Liebherr Components explained in its press release announcing its bauma exhibition plans that its system approach with the integration of a compressor and power electronics enables weight and cost savings, as well as reliable technology that is easy to integrate into the vehicle.

ZF to Exhibit Safe, Efficient and Electrified Solutions

Technology company ZF Friedrichshafen plans to showcase various components and system solutions which it said in a press release about its attendance at bauma will aid with the reduction of emissions at construction sites while improving productivity and safety.

These will include products to enable electrification of machines such as the eTRAC electric drive system. This driveline system includes electric motors in three voltage options. It can be combined with other components such as axles and inverters to provide OEMs with a full system solution. eTRAC also includes electric central drives which can be adapted to meet the needs of medium- and large-sized equipment. An electric PTO is available to accompany these drives to operate a machine's working hydraulics.

ZF noted in its bauma press release that efficiency will play just as integral a part in decarbonization efforts as electrification or other alternative energy systems. As such, the company continues to make improvements to so-called conventional technologies. Its ERGOPOWER powershift transmission, for instance, can help provide a fuel savings of up to 15%.

In regards to safety, the company is working to bring many technologies developed for the passenger car and commercial vehicle segments to construction and other off-highway equipment applications. One such example is radar-based environment perception technology which will better enable machine operators to see people and objects in their vicinity. These types of technologies are also vital for the development of semi- and fully-autonomous machines and systems.

The company also plans to launch the next generation of its Redulus4F Industrial Gearbox Series and Advanced Serviceability Solutions which provide condition monitoring. ZF said the gearbox has a flexible and compact design which allows for over 2,000 design combinations to fit OEMs' various application needs.

Twenty sizes are available which the company said supports up to a 40% increase in torque; it features a torque range of 99-5,800 kNm. A smaller outer diameter aids with the compact design of the gearbox which is also lighter in weight and requires less packaging space to help simplify installation.

The gearbox includes ZF's ProVID Condition Monitoring System which continually monitors operational performance. Doing so helps machine owners better manage their equipment and minimize unplanned downtime which can be costly for mining and construction operations.

Yanmar Introducing Electrification Strategy

Equipment and engine manufacturer Yanmar has announced it will introduce its strategy for electrification of off-road machinery during bauma 2022. As part of this strategy, the company aims to be an all-in-one systems integrator offering engineering, design and manufacturing of electric powertrains. It now joins a continually expanding list of engine manufacturers, including Cummins and Briggs & Stratton, who are adding electric power systems to their portfolio.

READ MORE: Electric Vehicle Development to Grow Over Next Decade

In April 2022, Yanmar acquired majority ownership of battery technology company ELEO Technologies B.V. whose modular batteries it felt would help with its own electric power system developments. ELEO is now building a new battery production plant to help increase capacity and meet growing demand for battery systems.

During bauma, Yanmar will feature an electrified demonstration vehicle which shows how its technologies for electrification can be deployed. It will be powered by an electric drive and 48V batteries with fast charging capabilities said Yanmar in its press release announcing the electrification strategy debuting at bauma. Additionally, it said the vehicle demonstrates the company's ability to be a system integrator capable of equipping machines with all necessary components for electrification.

Caterpillar Automation, Services and Zero-Emissions Solutions to be Displayed

Caterpillar Inc.'s Germany-based dealer Zepplin will exhibit a variety of the company's construction machines at bauma 2022 in both the indoor and outdoor exhibition areas. Over 70 different pieces of equipment and attachments are anticipated to be on display.

In addition, the company's various technology solutions will be on display. This includes the Cat Command Station which allows remote operation of machines from a nearby or distant location. It is part of Caterpillar's various automation technologies which enable mining or construction sites to stay productive while keeping operators in a safe working environment.

Cat Grade Assist for excavators will also be on display. This automation technology makes use of machine position sensors as well as depth and slope parameters set by the operator to enable automatic control of the excavator's boom and stick movements. Doing so helps to improve accuracy of the work tasks and efficiency as there is less rework that needs to be done.

Caterpillar has also announced plans to introduce electric powered equipment currently under development at the show. Battery-electric and other alternatively powered machines are an area in which the company is focusing R&D efforts to aid customers with carbon reduction goals. A modified version of its tethered electric Cat MH3024 material handler will be among the equipment displayed as a demonstration of a zero-emissions machine capable of being used indoors.

At MINExpo 2021, the company announced 100% of the new products it introduces from 2030 and on will be more sustainable than the previous generation. This includes development of alternatively powered machines as well as improvements to engine powered equipment, which will still be necessary in many applications for years to come. For the latter, design changes to help reduce fuel use and improve efficiency will be made.

Komatsu Premiering Electric and Efficient Machines

At Komatsu Europe's 4,550 m2 booth, the company intends to showcase 27 new and well-known machines and products. These include several electric powered pieces of equipment which will help customers achieve emissions-reduction goals. Analytics and digitization tools are also key solutions the company said in a press release it intends to feature during the event.

A unique feature the company has noted that will be part of its exhibit is a Virtual Stand. As Komatsu explained in its press release announcing its presence at bauma, the Virtual Stand will transport attendees to the near future to get a first look at upcoming innovations in its wheel loader designs.The PC4000-11 electric drive excavator is one of several machines set to be displayed by Komatsu at bauma. This hydraulic excavator features electric drive technology which helps it to perform in a more efficient manner, aiding fuel efficiency and emissions reduction for customers. The machine's CANbus assures optimized performance of the engine and hydraulic pumps, further benefiting efficiency and energy use.

Another machine to be displayed is the new WA800-8 wheel loader. According to Komatsu, the hydraulics of the machine are improved through the inclusion of a CLSS hydraulic system which uses variable displacement piston pumps to provide power on demand. Hydraulic oil is kept cool with this improved system design, aiding energy efficiency and fuel use.

To demonstrate the company's Intelligent Machine Control technology (iMC 2.0) a D71Pxi-24 dozer will be on display. The iMC 2.0 makes use of integrated software and sensors to create driver assistance system to ease machine movements as well as automate some functions.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: