Motion Controller Provides Synchronized Motion of Multiple Axes

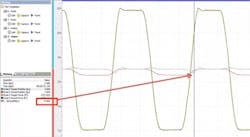

Delta Computer Systems Inc., Battle Ground, Wash., recently introduced an enhanced motion-control synchronizing feature for press applications. Historically, multiram presses have used very heavy guides and platens to prevent skewing. Delta’s RMC150 motion controller now offers electronic position-force synchronization that gives lighter machines more-accurate control of total force while keeping ram positions within a few thousandths of an inch of each other. The two figures show the minimal skew obtained with a highly uneven load.

Delta’s RMC 75 controller is intended for applications requiring two axes of motion. For larger machines, the RMC151E controller can handle up to six axes if the force is obtained via pressure sensors (two per ram), or up to eight axes of position-force control if load cells are used.

Delta CEO Steve Nylund explained, “Machine builders want precision and repeatability when executing position, pressure, and force control in all multiaxis applications. This feature can help deliver high performance in multiram applications even when loads are very uneven.”

For more information, call Bill Savela (360) 254-5435, e-mail [email protected], or click here to see a demonstration video of the enhanced motion control synchronizing feature.