Transforming Design Workflows Through Model-Based Engineering

Key Highlights

- Model-based engineering utilizes digital models that can be shared across teams and evolve throughout the product lifecycle to speed up design, testing and validation of motion system technologies.

- Workflows can become more automated through model-based engineering to help minimize errors, accelerate analysis, and create reusable assets that scale across programs and teams.

- Adopting model-based engineering as an organizational capability can foster innovation, improve product quality, and support more resilient engineering systems.

Model-Based Engineering (MBE) has been part of engineering practice for years, sometimes embedded deeply in connected workflows, other times applied in isolated pockets within specific teams or disciplines. What is different now is the context around it.

The technology landscape is shifting rapidly with the rise of artificial intelligence (AI), accelerated automation, and emerging agentic AI capabilities. Together, these trends are reshaping how engineering gets done and raising expectations for speed, quality, and collaboration.

In this environment, MBE is moving from a “nice-to-have” toolset to a core enabler of how modern engineering organizations operate and innovate.

Why Adoption of Model-Based Engineering is on the Rise

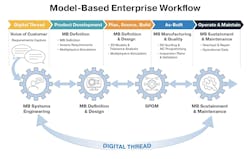

As AI becomes more integrated into everyday workflows and automation scales across the product lifecycle, MBE is evolving just as quickly. Models are no longer static artifacts; they are becoming living, connected representations that link requirements, physics, controls, data, and decisions. Instead of relying primarily on documents, handoffs, and late-stage testing, leading teams are using model-centric, automated workflows to gain system-level insight earlier, explore more options, and reduce risk.

Organizations that lean into this shift can turn growing motion system complexity into a competitive advantage, while those that hesitate will face higher engineering and production costs and increasing difficulty keeping pace with the speed of change.

Engineering teams are under increasing pressure to move faster, reduce risk, and deliver solutions that work reliably in complex, real-world systems. Traditional product development still has value, but it often struggles to keep pace.

In addition, fluid power and other motion system designs are becoming more complex while performance margins tighten, prompting many organizations to rethink not just the tools they use, but how engineering work itself gets done.

That shift is driving growing adoption of MBE. At a practical level, MBE replaces static documents with connected models that evolve across the entire product development lifecycle. Requirements, design intent, physics behavior, and verification results are captured directly in models, enabling teams to explore options earlier and make decisions with greater confidence.

For companies like Parker Hannifin where the focus is on delivering system solutions rather than isolated components, this approach is especially powerful. A valve or actuator only delivers value if it performs well within a larger hydraulic or other motion system. MBE makes it possible to evaluate system behavior early — before hardware exists and to iterate efficiently as requirements change.

Benefits of Using Model-Based Engineering

There are many opportunities to improve workflow and final motion system designs when an organization implements MBE.

Faster Decision-Making and Fewer Documents

Traditional engineering workflows rely heavily on drawings, spreadsheets, test reports, and presentations. These artifacts are necessary, but they often lag behind the design and quickly become outdated. More importantly, they tend to describe decisions after they are made rather than enabling better decisions upfront.

MBE shifts engineering toward a decision-centric approach. Models become the primary means for exploring tradeoffs, understanding sensitivities, and evaluating risk. Instead of asking what a report says, teams ask what the model predicts and how confident they are in that prediction.

As a result, MBE shifts the focus from explaining decisions after the fact to making better decisions earlier when change is cheaper and risk is easier to manage.

This shift improves traceability, accelerates iteration, and reduces reliance on late-stage testing to uncover issues that could have been identified much earlier.

Advanced Simulation and Co-Simulation

A core enabler of MBE is advanced simulation, particularly when multiple physical domains interact. In hydraulics and motion control, performance is shaped by fluid dynamics, mechanical motion, controls, materials, manufacturing tolerances, and transient operating conditions. Capturing these interactions requires more than isolated calculations.

Multi-physics simulation and co-simulation allow engineers to study realistic system behavior before hardware is built. System-level models can be coupled with detailed component simulations to understand how design choices affect overall performance. When applied with discipline, this approach reduces the number of physical prototypes required, shortens development cycles, and increases confidence that designs will perform as intended.

Equally important is repeatability. For MBE to scale across teams and programs, models must be structured, governed, and reusable—not one-off analyses that live only on individual workstations.

Automating Engineering Workflows

While models are central to MBE, many of the largest gains come from automating engineering workflows. Manual data transfers, inconsistent setup steps, and ad-hoc analysis processes consume time and introduce errors.

Standardized, automated workflows — covering model setup, execution, post-processing, and reporting — reduce time-to-answer and improve consistency. Automation allows engineers to focus on interpreting results and making decisions rather than managing tools and files. Over time, these workflows become reusable assets that can be applied across programs, product families, and teams.

Digital Engineering and the Connected Thread

To fully realize the benefits of MBE, models must exist within a connected digital engineering environment. A digital thread links requirements, design data, simulation results, and verification artifacts across the lifecycle. This improves transparency, supports reuse, and enables collaboration across distributed teams.

For organizations with broad portfolios, a connected engineering thread allows proven methods to propagate across divisions rather than remain siloed. Knowledge is retained in models and workflows — not just in documents or individual experience.

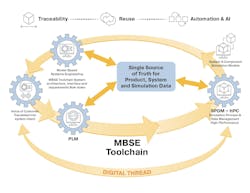

Creating a Model-Based Systems Engineering Approach

MBE is increasingly becoming the connective tissue across the entire product ecosystem, linking OEMs, Tier 1 and Tier 2 suppliers, and key partners through shared digital models rather than fragmented documents — leading to the creation of a model-based systems engineering (MBSE) approach in which information, feedback and system requirements are shared via digital models.

Instead of passing drawings and spreadsheets back and forth, stakeholders collaborate through models that carry intent, performance context, and constraints in a consistent, machine-readable form. This enables more accurate, timely, and transparent information flow across organizational boundaries, reducing rework, misalignment, and waste while improving overall product quality and sustainability.

We are already seeing early versions of this ecosystem-level collaboration take hold in aerospace, and many OEMs outside that sector are now moving in the same direction. As AI and automation rapidly become part of everyday engineering workflows, seamless data and knowledge exchange across companies will be essential, not optional.

Learn more about MBE and MBSE

Read the below articles from Machine Design, a partner publication of Power & Motion, to learn more about how model-based engineering and model-based systems engineering are being used to aid the design of machines and systems.

What’s up with model-based engineering?

The Digital Evolution of Heavy Machinery — Understanding Model-Based Systems Engineering

Model-based approaches provide the foundation for this shift, enabling automation, analytics, and intelligent decision-making to scale across the value chain and support more sustainable, resilient engineering systems in the years ahead.

MBE is most effective when treated as an organizational capability rather than a one-time initiative. Shared standards, reusable templates, and communities of practice help raise the baseline across teams while avoiding duplication.

Within Parker Hannifin’s Motion Systems Groups and Hydraulic Valve Systems Divisions, this approach enables advanced simulation, automation, and systems thinking to scale consistently across programs.

Model-Based Engineering is not about replacing engineering judgment. Rather, it is about strengthening it. By shifting from documents to models, from manual processes to automated workflows, and from component thinking to system thinking, engineering teams can deliver higher quality solutions faster and with greater confidence.

For companies like Parker, MBE and MBSE are natural extensions of a system-solutions mindset — supporting innovation that scales across a diverse portfolio while meeting real customer needs.

This article was written and contributed by Bipin Kashid, engineering manager, chief engineer at Parker Hannifin.

About the Author

Bipin Kashid

Bipin Kashid is an engineering manager, chief engineer for Parker Hannifin.

Leaders relevant to this article: