What are the Advantages of Using a Digital Pressure Transmitter?

Key Highlights

- Adoption of digital pressure transmitters is on the rise due to increased automation and demand for more precise measurements.

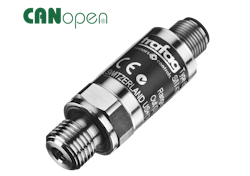

- Digital pressure transmitters offer the ability to send and receive signals via communication protocols such as CANopen which provides numerous benefits.

- There are several advantages digital pressure transmitters offer over analog versions which can help create more productive and efficient operations.

Pressure transmitters and other types of sensors are increasingly moving from the analog to the digital world, enabling a range of benefits from improved functionality to enhanced diagnostics capabilities.

Rising adoption of automation and demand for more precise pressure measurement are helping drive growth for digital sensing devices according to a 2025 report from Data Insights Market. Per the report, advancements in sensor technology, miniaturization and increasing adoption of the Internet of Things (IoT) devices are also helping drive growth for the digital pressure sensor market.

Given the increasing prevalence of digital pressure transmitters in the market, it is important to understand what they are and the advantages they provide over analog options. This will make it easier to determine if these digital sensing devices are the right choice for your application requirements.

What is a Digital Pressure Transmitter?

Pressure transmitters — also referred to as a pressure transducer — are a mechanical device designed to measure the expansive force of a liquid or gas, making them a good fit for many hydraulic and pneumatic systems. These sensors convert pressure measurements into electrical signals, enabling their use for control and monitoring in various applications.

Fluid flow regulation, safety monitoring and machine diagnostics are some of the common use cases for pressure transmitters.

Because they can withstand harsh environmental conditions such as temperature fluctuations, corrosion and vibrations, pressure transmitters can be used in construction equipment, robotics, the oil & gas industry, manufacturing and other demanding applications.

Watch the below video from Trafag Inc. to learn more about how pressure transmitters work.

While analog and digital pressure transmitters perform the same task, how they output their signal is where they differ. Analog devices provide a continuous current or voltage signal that can be beneficial for many applications such as those susceptible to noise.

Digital pressure transmitters, on the other hand, output a digital signal that is then transmitted electronically. They can transmit information using various communication protocols, such as CANopen and IO-Link, enabling the ability to ‘talk’ with other systems and a range of other benefits.

The Differences Between CANopen and IO-Link

CANopen and IO-Link are among the most commonly used communication protocols in industrial and mobile machinery applications.

CANopen is based on the Controller Area Network (CAN) bus and supports real-time communication, advanced network management and standardized device profiles. It is robust and offers high-speed capabilities which has led to its widespread adoption in demanding industrial applications, heavy machinery and medical equipment.

IO-Link, on the other hand, is a point-to-point communication protocol specifically designed for smart sensors and actuators. It enables bidirectional data exchange for process information, diagnostics, and parameterization, which aids its use for Industry 4.0 initiatives and smart factory environments.

Advantages of Using a Digital vs. Analog Pressure Transmitter

Although analog and digital pressure transmitters both do the same job, there are four key advantages digital versions offer over their analog counterparts.

1. Enhanced Functionality

Digital pressure transmitters are commonly equipped with microprocessors, enabling them to provide enhanced functionality such as advanced signal conditioning for more accurate and stable pressure readings. In addition, digital devices can better compensate for temperature variations to furth ensure the accuracy of pressure measurements in a range of operating temperatures.

The ability of digital pressure transmitters to utilize communication protocols also enables them to provide enhanced functionality compared to their analog counterparts. For instance, use of CANopen protocols allows multiple data points to be transmitted at the same time such as pressure and temperature readings for more advanced monitoring and data analysis.

The more information machine owners can get, the better their ability to monitor performance and address potential issues before they become major downtime issues.

2. Remote Monitoring and Diagnostics Capabilities

Another benefit of digital pressure transmitters is the remote configuration, diagnostics and troubleshooting capabilities they can provide. This is because they can both send and receive signals via communication protocols like CANopen and IO-Link.

Having the ability to remotely access data from these devices helps to create safer operations. Transmitters and other sensor devices are often located in hard-to-reach areas of a machine. Allowing remote communication with them prevents personnel from potentially putting themselves in harms way by physically interacting with the machine.

In addition, a machine may be in a remote or dangerous location which can present challenges. Here again the ability to access the transmitter’s data from another, safer location via communication protocols enables performance to be monitored and maintenance issues addressed without negatively impacting the safety of personnel.

These remote capabilities create more efficient operations as well. They make it easier to continuously monitor performance and be proactive about addressing maintenance issues as they arise which might otherwise lead to costly downtime. As such, operations can remain more productive and better utilize their resources.

Read the below articles to learn more about the role sensing technology like pressure transmitters can play in enabling predictive maintenance systems.

3. Design Flexibility and Reconfigurability

Digital pressure transmitters also offer the benefit of easily adapting to specific application requirements. Use of digital systems within the transmitter enables them to be reprogrammed as necessary to meet the needs of new applications, helping to reduce inventory while increasing flexibility.

Reprogramming can be done across a network of sensors with minimal effort required, allowing for the adjustment of various sensing characteristics such as measurement thresholds. This helps to save time and resources for both design teams and machine owners by enabling changes to be made quickly, eliminating the need for potential downtime to install a new component or having to keep multiple sensor types on hand.

4. Reduced Wiring Complexity

In systems requiring multiple sensors, digital pressure transmitters offer the benefit of reduced wiring complexity. Use of communication protocols such as CANopen enable several devices to communicate on a single shared line.

Up to 255 devices can be supported on a single communication line when using the CANopen standard while other protocols like CAN FD (Flexible Data-rate) allow even more devices to use a single line.

Analog pressure transmitters, on the other hand, require individual wire connections to a controller. If multiple transmitters are needed, then a wire for each sensor used is required as well which can add design complexity for machine OEMs and system integrators. This also adds to the amount of space taken up in a machine.

If fewer wires are required, a system can be more compact and efficient which are growing criteria in many mobile and industrial machinery applications. There is less space available in machines, necessitating use of compact systems when possible while reducing the number of installed wires helps to minimize overall machine weight, leading to lower energy consumption.

As with any technology, determining whether to use an analog or digital pressure transmitter will depend upon application requirements and other factors such as environmental conditions. With the many advantages digital pressure transmitters offer — and the increasing digitalization of components, systems and machines — they are frequently becoming the technology of choice for many machine OEMs and their customers.

This article was adapted with permission from one originally written and supplied by Trafag Inc., a developer of pressure, temperature and gas sensors.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: