The 4 Ways Software and Communication Protocols Enable EV Safety

What you’ll learn:

- Where software and communication protocols are utilized within the electric vehicle ecosystem.

- How software and communication protocols contribute to safe operation and charging.

- The advantages software-based architectures can provide versus hardware-based options.

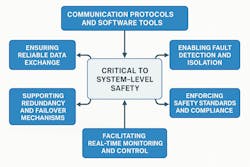

Safety is a critical element to consider when developing on- and off-road electric vehicles due to the various electronic components and high voltages utilized in them. The integration of software and communication protocols has become integral to ensuring both safe operation and charging of these vehicles.

Rahul Baliga, Vice President of Integration at Delta-Q Technologies, a ZAPI GROUP company, outlined the four key ways he sees software and communication protocols being utilized within the electric vehicle (EV) ecosystem and the role they play in ensuring safety is achieved.

1. Ensuring Safe Interaction with Charging Infrastructure

When looking at the electric vehicle ecosystem, the charging infrastructure is as important an aspect to consider in terms of safety as the vehicle itself. Therefore, software and communication protocols are typically included in the electric vehicle supply equipment (EVSE) which is the device used to supply electrical power for recharging a vehicle battery.

Why This Matters to the Hydraulics and Pneumatics Industry

Construction equipment, agricultural machinery, forklifts and other heavy-duty vehicles in which hydraulics and pneumatics are utilized continue to become more electrified through the integration of batteries, electric motors and other components.

This is bringing about a number of design changes for fluid power systems because they are now interacting with or being driven by electric powertrain systems. Therefore, it is important for those developing hydraulic and pneumatic systems to have an understanding of electrification related technologies and design considerations to ensure all components will work together in a safe and efficient manner.

Read more about the importance of safety when developing electric vehicles and systems in the below articles:

How to Safely Work with High-Voltage Systems

Safety Factors to Consider When Working with Electrification Systems

Navigating the Complexities of Battery and Charger Integration for Electric Vehicles

Baliga explained that communication protocols are included on charging stations, the cable that plugs into a vehicle for recharging, as well as onboard chargers so all of these devices can communicate with one another to ensure safe and proper charging of an electric vehicle.

“The [onboard] charger communicates with the charging station, and that communication has different standards,” he said, based on where in the world it is being used. Europe has its own standard while North America and China each have their own communication standards as well.

He said it is critical that all of these standards are properly coded onto chargers to ensure the software embedded on the charging station can accurately communicate with the software on the electric vehicle. “This is important because when you look at the electrical safety piece of it, there is something called a ground fault interrupt (GFI) which is essentially what prevents somebody from getting electrocuted. That is a critical parameter in terms of software functionality,” said Baliga.

Another critical function the embedded software performs is preventing unwanted unplugging of the charging device. “The EVSE interface has a signal that turns on a small motor that locks the charging inlet so nobody can pull it out unless you cancel the entire charging session altogether,” he explained. “All that is initiated by software and done via underlying hardware.”

A third way software aids safety during charging is for the vehicle inhibit function. When a vehicle is connected to a charging station, you don’t want someone trying to drive the car away while it is plugged into the charger. Via software and communication protocols, the vehicle control unit is informed that a vehicle is plugged in and the unit will prevent an operator from driving away.

2. Compatibility with Various Battery Profiles

Software and communication protocols also play an important role in ensuring accurate communication between a charger and the batteries on a vehicle.

Lead acid batteries were the norm for many years in the electric vehicle space, but lithium-ion continues to increase in use for both on- and off-road applications. Baliga said that while passenger cars, construction equipment and other electric vehicle applications are switching to use of lithium-ion, there are a large number still utilizing lead acid.

Embedding software onto chargers ensures compatibility and proper communication with the various battery chemistries in the market.

Baliga said Delta-Q Technologies has worked with various battery manufacturers to do compatibility testing between its chargers and their batteries. “This is important because each battery has a different profile,” he said. “You have to do compatibility testing to ensure the battery profiles match [in terms of] current, voltage and thermal limitations.”

He noted that these profiles can vary not only from one manufacturer to another but also between different generations of batteries developed by the same manufacturer. “Delta-Q has done an immense amount of deep integration testing with a wide variety of manufacturers and different sets of batteries [and] a lot of these profiles are loaded onto chargers today,” he said.

Watch our panel discussion in the video below with Delta-Q Technologies and other experts from the electrification field to learn about the importance of keeping safety in mind during the design process.

When a design team selects the battery it wants to use, the appropriate profile is automatically loaded onto the charger to ensure compatibility and safety which includes preventing the battery from being overcharged or undercharged.

“It has safety protocols in terms of temperature so if a battery has a particular temperature profile, you do not exceed that temperature profile,” explained Baliga. “Things of that nature on the safety front is accounted for through the algorithms that have been loaded [onto the charger.”

He said that today’s Delta-Q chargers for lead acid batteries have over 200 different algorithms on them to help ensure safety. Those for lithium-ion batteries, however, have a more complicated software-based environment to work in.

“With lead acid batteries, the charger determines everything based on compatibility testing,” he explained. “When you move to lithium-ion, there is a slightly more complicated software platform.”

This is because the battery itself has a controller called a battery management system (BMS) and the vehicle has a controller called the vehicle control unit (VCU). These devices plus the charger itself all have intelligence built into them which need to communicate with one another to ensure safe operation and charging.

Baliga said the BMS knows exactly what it wants in terms of voltage, current and temperature which it communicates using specific protocols. The two main protocols used in the industry today are CANopen and J1939 (see sidebar below). Building these protocols into the BMS, VCU and charger is necessary to ensure proper communication between each of these devices.

The seamless real-time exchange of data these protocols enable are absolutely critical to the creation of a good customer experience while also ensuring safe battery charging, he said.

What are CANopen and J1939?

CANbus networks based on the CAN (Controller Area Network) standard have become commonplace within mobile and industrial machinery as a way for electronic control units (ECU) to communicate with one another.

There are two main protocols utilized to enable this communication, CANopen and SAE J1939. CANopen tends to be associated with industrial automation but can be used in a range of applications. J1939 was standardized by the Society of Automotive Engineers (now more commonly known as SAE International) and is the more commonly utilized protocol in automative applications.

Each has distinct data formats it uses and messaging structures to suit the various applications in which they are used.

3. Built-In Protections for Onboard Chargers

The third area in which software and protocols are utilized in the electric vehicle ecosystem is the onboard chargers. Baliga said it comes in the form of embedded firmware that is included to protect the charger itself and the overall electrification system.

“That includes many different safety parameters that we have added, whether it's voltage, current, or temperature,” he said.

He offered the example of voltage protection. Set points for overvoltage and undervoltage conditions are built into the firmware so that if any sort of voltage surge suddenly occurs on the vehicle, the appropriate actions to protect the charger and battery system will be initiated. “If there are brown out conditions and the voltage sags, then the charger has the capability to fold back its power so that it doesn’t blow the upstream breaker,” he explained. “This is all done through embedded firmware within the charger.”

If a voltage surge or other safety issue occurs, the charger will communicate that information to the battery and VCU via the vehicle’s CANbus to ensure all parts of the electrification system operate in the safest manner possible.

Baliga said comms loss is another critical safety feature in Delta-Q’s chargers. “If for whatever reason communication with the vehicle is lost, the charger instantly shuts off,” he said. “It provides a comms lost alarm so vehicle users are aware something is wrong.”

He said in the past, these kinds of protection features were done through hardware but today it’s all done through embedded firmware or software. “Over the past 15-20 years, software has become such a huge part of the product development cycle.”

This helps to simplify system designs and add other features as desired. Baliga explained that in the past with a hardware-based design, you would have to map out every single resistor and capacitor which had to then be calibrated to the exact set point you wanted for your overvoltage or other protection feature. And once completed, it could never be changed.

With software-based designs, firmware and other intelligence is built into a microprocessor and there is no longer a need for all the circuitry. And should a feature need to be changed or added, a firmware update can be provided to the customer. “How quickly we are able to address customer issues or customer needs is now a lot faster,” said Baliga.

Costs are reduced as well because there is less wiring and circuitry required, minimizing the number of components to purchase and install. Today’s software-based systems typically contain basic power connections and one communication cable connected to the VCU, BMS, charger and other components in the electrification system.

“If you look at a lot of the conversations in the electric vehicle industry today, [there is a lot of discussion] about localizing the different controllers on a vehicle, and how it can help reduce a ton of cost on the wire harnessing end by [communicating] through specific protocols,” he said.

4. Simplifying Diagnostics and Upgradability

The final area in which Baliga sees software and communication protocols playing an important role in ensuring the safety of electric vehicle systems is in terms of diagnosing potential performance issues and enabling system upgrades.

In the past, if something went wrong it was hard to determine why. Chargers were very basic, he said, and would provide an alarm when a performance issue occurred but not be able to specify what caused it. Today’s software-based vehicle architectures, on the other hand, can communicate both faults and alarms to users.

One way Baliga said these can be communicated is through a vehicle’s on-board diagnostics (OBD) system — an electronics system that can monitor and report maintenance issues. The other software protocol that is used is called unified diagnostic services (UDS). “UDS is another form of software protocol that communicates diagnostic information via the vehicle control unit and eventually to the user or whomever may need to use it,” he said.

By having these diagnostic capabilities built in, vehicle owners can be alerted to performance issues and address them as soon as possible before a larger, potentially more dangerous problem occurs.

Utilizing a software-based architecture on electric vehicles makes it easier to upgrade various systems and features as well. Typically, a vehicle simply needs to be in range of a Wi-Fi or Bluetooth connection to initiate any upgrades an OEM or system supplier may want to provide. “In the past, you would never see that because none of the vehicle’s components were software based,” said Baliga. “Today, with all the components being software based and having a controller, including the charger, you have the capability to remotely upgrade.”

This makes it possible to quickly add capabilities and features, including those related to safety. He offered the example of a charging station customer which discovered a potential safety related bug with its chargers. New firmware was provided to the customer which was broadcast to the thousands of charging stations it has all over Canada, enabling a quick and easy fix to prevent a safety issue from occurring.

“From a user experience and a safety perspective, this was a potential safety hazard that they had on their charging station that they were able to upgrade almost instantly across the nation,” said Baliga.

He concluded by saying that as the industry has evolved into a more software-based world, it has opened up opportunities for engineers, OEMs, charger manufacturers, and others in the electric vehicle ecosystem to provide a number of capabilities related to safety and the user experience that were not possible in the past with hardware circuits.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: