Troubleshooting Challenge: Telescopic Cylinder Drops Unexpectedly

Officials at a foundry that produces aluminum engine blocks designed a transfer line that would lower four engine blocks at a time from an overhead conveyor. The system then transferred the blocks from the facility’s machine shop area to another section for final degreasing and a protective coating process.

The vertical lift system worked at first but then developed a dropping problem. The lift was powered by a single-acting telescopic cylinder with 20-ft. stroke. The cylinder had two moving stages and was retracted by the weight of the moving skid system that held the engine blocks being transferred.

When the lift received a signal to lower the engine blocks, the outer moving stage would retract first. When it bottomed out, the inner section would suddenly retract while the outer moving stage would fully extend. This action caused a sudden drop of 5 to 6 ft., but it would then continue retracting at the proper speed.

Any idea why this would happen?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by October 25, 2017, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Challenge:

Series Manifold System Can’t Reach Pressure

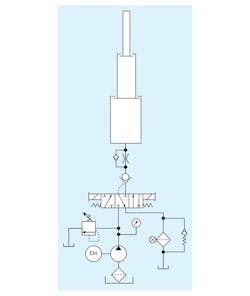

Pilot pressure on pilot-operated valves can be difficult to fully understand. The D08 manifold had ports drilled as a source of external pilot pressure. For some reason, the original design did not use the external option.

When the old valves were examined, it was noticed that the X port in the bottom of the old valves had a solid plug installed. This isolated each valve’s pilot pressure to its main pressure port. The new valves should have had these solid plugs installed to block the external port. Instead, the plugs had been removed. With these plugs missing, pump flow was exiting thru the X port passages that just happened to pass all the low-flow, high-pressure fluid back to tank at the unloading valve’s pressure.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: