Diagnose Pumps with Your Smartphone

This file type includes high-resolution graphics and schematics when applicable.

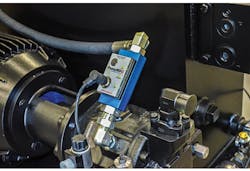

The PumpMD is a diagnostic device that monitors the condition of oil in hydraulic axial-piston pumps. Many manufacturers offer hydraulic axial-piston pumps, and dimensional and performance characteristics will seldom be the same between any two pumps. Because of these differences, the PumpMD is configured from specifications provided by the customer.

The latest version of the PumpMD is Wi-Fi-enabled for use with its Internet of Things (IoT) mobile app, allowing users to view current and historical data of one or more hydraulic pumps, including efficiency rankings, what’s trending, and alarm levels.

Causes and Action

After an axial-piston pump is placed into service, its piston shoes will wear over time, leading to increased case drain flow. The piston shoes wear in proportion to the cleanliness of the oil being pumped, and dirty oil will accelerate the wear. As wear increases, so does the oil volume to the pump case, case temperature, and case pressure due to the backpressure from the case drain port.

High case pressure can affect the hydrostatic balance of the pump’s pistons and may cause leakage through the pump shaft seal. The PumpMD monitors these three indicators (flow, temperature, and pressure) with LED indicators that change from green to red if any of the three parameters exceeds the presets for a specific pump size from the pump manufacturer shown in the model code.

Because PumpMD is tailored to a specific pump, customers will need the following information before using its web-based configurator to select the PumpMD that will best work with their particular pump:

• Case drain port size (SAE only)

• Continuous speed (rpm) of the drive motor

• Displacement of the axial-piston pump. (cc or in.3)

• Maximum allowable pressure of the pump’s case drain (psi)

For more information, call PumpMD at (844) 786-7631, or visit www.mypumpmd.com.