Belt Drive Pptimizes Pump Dynamics for Bobcat

There's a good reason why the engines of Bobcat skid-steer, compact track and all-wheel steer loaders run quieter, last longer, and burn less fuel than other brands.

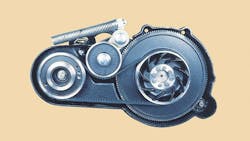

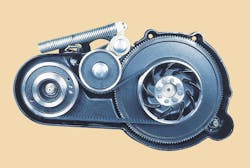

Adapting technology from the automotive industry, Bobcat loaders use a single belt and sheaves to transfer power from the engine to the hydraulic pump. A spring-loaded idler pulley keeps proper tension on the belt. Plus, easy access makes replacing a belt simple and inexpensive.

Competitive loaders transfer power from the engine directly to the hydraulic pump. Because the pump runs at the same speed as the engine, the pump may not operate at the proper speed for optimal hydrostatic and hydraulic functions.

If a small-displacement pump is used, the engine must run at high speed to generate adequate flow. The result is high fuel consumption, excessive noise, and reduced engine life. Using a larger displacement pump allows lower engine speed, but sacrifices hydraulic efficiency.

The Bobcat solution allows uses a belt drive to increase speed from the engine. As a result smaller, a smaller pump can be used without having to run the engine at fuel-guzzling speeds.