Fluid-operated clutch enhances bow thruster

Steering a commercial boat or large yacht can be similar to driving a heavy car with bad brakes. It's difficult to stop, and response to the rudder is slow. This usually poses no problem in the open sea, but it can be a real challenge to maneuver the vessel in a congested marina or when docking. This is where a bow thruster comes in.

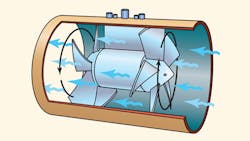

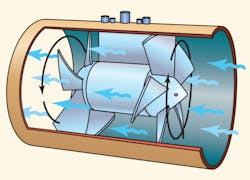

A bow thruster consists of an open-ended tube that runs through the underwater sections of the hull near the bow and perpendicular to the keel. A propeller mounted at some point inside this tube can rotate in either direction. The helmsman selects the rotational direction and actuates the propeller. As a result, the bow thruster sucks a solid stream of water in one end of the tube and forces it out the other, pushing the bow sideways and augmenting the rudder to make steering more responsive.

Two props are better than one

Traditional single propeller systems generate thrust by accelerating water in the axis of the propeller shaft. However, the water discharged by the propeller also rotates. This is due, in part, to the friction between the surface of the propeller and the water. This rotational component does not produce thrust, but it does consume energy. That's why Fred Knowles, of Hansen Marine Engineering Inc., Marblehead, Mass., likes the TRAC thruster from American Bow Thruster, Rohnert Park, Cal. The TRAC thruster is designed with two counter-rotating propellers. By turning the propellers in opposite directions, the efficiency of the TRAC thruster becomes 10 to 15% greater than that of single propeller systems.

Single propeller thrusters have no way to prevent losing energy to the rotational forces imparted into the water. Because this loss increases with speed, there is a practical limit to the amount of input horsepower that can be applied to single propeller systems. TRAC's counter-rotating propellers cancel out rotational losses so greater horsepower can be input into a given tunnel diameter. As a result, TRAC thrusters generate up to 50% more thrust than competing thrusters of the same diameter.

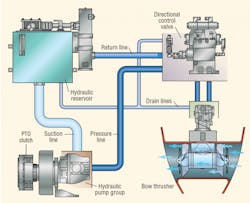

Hydraulics provides powerBecause the bow thruster propellers are underwater, a hydraulic motor is a practical means of power transmission. For even higher overall efficiency, TRAC hydraulic thrusters are fitted with piston-type motors. These motors are 10 to 18% more efficient than the vane or gear motors used in most other thrusters. As a result, overall efficiency of the TRAC (in terms of thrust per input horsepower) could be 20 to 33% greater than competing products.

The vessel's engine drives the hydraulic system's pump through a power takeoff (PTO). And because the bow thruster is only used for relatively short periods of time, it's logical to disengage the bow thruster power train with a clutch during idle periods. This minimizes wear and tear on the pump and auxiliary drive, and saves fuel by eliminating energy consumption by the thruster when not in use.

Hansen Marine specifies PTO 250 clutches from Logan Clutch Corp., Cleveland, for this application. The heavy-duty PTO 250's compact, in-line configuration suits the power train well, as does its high torque rating. Because the clutch is air-actuated, mechanical linkages are eliminated, and the bow thruster can be rapidly engaged or disengaged remotely from the vessel's control station.

Logan's PTO 250 clutches incorporate a multiple disc pack design, enabling them to transmit high torque within a compact housing. They are corrosion resistant, require no external lubrication, and are self-adjusting. Unlike springs, the compressed-air actuation selfcompensates for wear to provide consistent performance.

For more information on Logan clutches for mobile and industrial applications, call Logan Clutch at (800) 525-8824 or visit www.loganclutch.com.