Snow plows are familiar winter-time sights in northern climates. But pushing tons of snow off of roadways often is only part of their job. Hills, sharp turns, intersections, and high-traffic areas usually need salt, sand, cinders or other materials to improve vehicle traction for traffic to keep moving.

The challenge of distributing these materials is applying just the right amount because some areas require a greater or lesser concentration of material, and the problem is exacerbated by varying travel speeds of the vehicle. Then there’s the economics. Applying too little can render the material ineffective, whereas applying too much wastes money and may harm the environment. Plus, applying too much material robs productivity by requiring drivers to replenish their supplies more often.

To make the job easier for drivers, and more economical and productive for fleet operators, we developed our Direct Cast on-the-go directional control spinner system, which gives drivers the ability to adjust the spray pattern from inside the comfort of a vehicle’s cab, at any time.

The Direct Cast system can cover a single lane (left, center or right), two lanes (center and left or center and right) or all three lanes at once. Operation is automatic from a toggle switch and control screen. It has been tested and proven to spread sand, salt, pre-wetted salt, slurry, or similar materials efficiently and effectively.

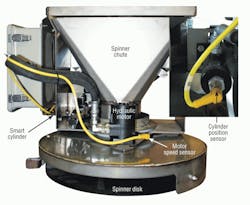

The salt, sand, or other material flows out of a truck’s dump bed or hopper into a chute that directs the material onto a spinner disk. The spinner disk’s top surface contains axial fins that fling the material outward — the faster the rotational speed of the disc, the wider the spread pattern. Rotational power for the disk is provided by a hydraulic motor. But we take this process to the next level by also using hydraulics to control the width and direction of dispersion. A hydraulic cylinder positions a deflector that controls direction of dispersion.

Closing the control loop

Direct Cast controls the dispersion of materials by allowing the operator to change spread patterns while driving. Most other units require the driver to stop, walk to the back of the truck, and make adjustments. With Direct Cast, two adjustments are made from within the cab. One controls the width of the application area, and the other controls the direction of the spread — left or right of center or dead center. Doing so can prevent spreading material at oncoming traffic, parked cars, pedestrians, etc.

The spinner chute can be added to any salt spreader. A standard unit normally has only a spinner motor requiring 5 to 7 gpm at 1500 to 2000 psi. Our chute has a valve mounted in an enclosure that diverts some of the hydraulic flow to a feed rate cylinder. This cylinder controls where the material falls onto the spinner disk and the opening in the shroud.

The feed rate cylinder is double-acting with a 1½-in. bore and 6-in. stroke. It also has an integral linear displacement transducer from Rota Engineering for position feedback. Depending on control requirements for the application, the sensor emits either a PWM or analog signal. We also incorporate a speed sensor with the hydraulic motor for speed feedback to control width of the spread pattern. So with the cylinder position feedback and motor speed feedback, we achieve closed-loop control of direction of dispersion and width of the spread pattern.

A simple add-on

We have worked with several major manufacturers of snow and ice truck controls to integrate the controls into their newest systems. For new installations, we work with the truck builder to interface our controls with theirs. For retrofits and trucks with less expensive controls, we have a control-display that is added to the truck. It is a simple three-button control with visual readout that uses LEDs to show the driver where they are directing materials. One of the buttons is the on-off and is used for calibration. The other two buttons are the control buttons for width and direction.

This is a simple system that greatly increases the precision of where materials are applied to the road. In the past, attempts had been made to create precision placement chutes, but they were often too complex, which usually lead to clogging and failures due to the materials that different areas of the country spread on the roads. The Direct Cast system is a minor change to existing hardware but with a big upgrade of control. We proved we could reliably direct most any material by precisely controlling just a few factors. This is so close to existing hardware that minimal clogging occurs, and it fits easily onto most trucks.

We spent a lot of time on this through testing of prototypes, etc. so the final product was pretty close to plan. Cost and space are always a challenge, but I think this unit is right in line. Ease of controls and calibrations seem to be simple and reliable as well. Cost and longevity of the system are advantages for hydraulics in this harsh environment. The motor and cylinders are right near the road surface where the salt is being dispensed. So items in this area see the worst environment on a salting truck.

Shane Chesmore is lead design engineer at Henderson Products Inc., Manchester, Iowa. For more information, visit www.hendersonproducts.com.

|

Small sensor makes cylinders smart Linear displacement transducers from Rota Engineering use a microprocessor that transmits and receives signals from Hall-effect chips in a printed circuit board, which is contained within a corrosion resistant metal housing. A piston-mounted magnet causes a voltage drop when it passes over the Hall-effect chip. The microprocessor calculates the position of the Hall-effect chip and correlates the voltage drop to a proportional voltage, current, PWM, or CAN bus output. Mark Hoffman, of Rota Engineering’s U.S. location, explains, “Hall-effect sensors do not have as high a resolution as magnetostrictive sensors, which can achieve resolution of ten-thousandths of an inch. However, Hall-effect LDTs generally have resolution of 0.012 to 0.020 in. The tighter resolution of magnetostrictive LDTs is essential for many process applications, such as a rolling mill. Most of the time, though, 0.020 in. resolution is more than sufficient for mobile hydraulic applications.” An additional benefit of the Hall-effect technology is small size. In most instances, the overall length of a cylinder need not be increased when using a Hall-effect LDT. Also, the surface-mount technology tolerates high levels of vibration. “I think the neatest feature on this application, from a sensor standpoint, is that Henderson uses a screw-in version of our sensor. Henderson’s cylinder supplier prepares each cylinder by gun drilling its rod, machining #8 SAE threads into its end cap, installing our magnet and snap ring, and putting it into inventory. When a particular truck needs a smart cylinder, the cylinder manufacturer pulls the cylinder from stock, installs the Rota sensor and viola, instant smart cylinder.” For more information on linear displacement sensors from Rota Engineering, visit www.rota-eng.com or e-mail [email protected]. |

Here is a link to a YouTube video that shows the spreading capabilities of the Direct Cast system from Henderson Products Inc., Manchester, Iowa.

About the Author

Leaders relevant to this article: