Helical gears make for quieter work areas

Reducing noise in the workplace has become a necessity for many companies, and both industrial and mobile hydraulic systems have been identified as significant contributors. One of the main generators of noise in a hydraulic system is the pump and the pulsating flow it produces.

Piston, vane, and gear pumps all produce different sound signatures, and pump size, rotational speed, and operating pressure affect noise output. But even when operating under identical conditions, different pumps of the same design can produce different sound signatures. For example, a gear pump with fewer or more teeth than another can generate more or less noise. Not only does the number of gear teeth affect noise output, but the geometry of the teeth does too.

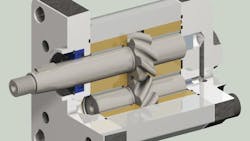

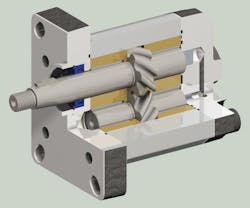

Settima Flow Mechanism SRL, Piacenza, Italy, has developed a gear pump with helical teeth. According to Settima’s Agostino Martini, teeth of the Continuum pump are in continuous contact. The result is operation with an average noise level of 52 dBA.

Martini explained that gear pump noise has two distinct origins — mechanical and hydraulic. Mechanical noise is inherent to meshing of gear teeth. Hydraulic noise, however, is generated by turbulence of fluid through the pump. This noise and vibration stem from

• cavitation,

• peak pressures that arise from trapping of fluid between the top and the bottom of the tooth, and

• flow pulsation from meshing that causes a pressure pulsation.

Not only does cavitation cause noise, but it can lead to structural damage of internal surfaces. Martini continued, “This phenomenon is tied to the average speed of the fluid in the pipes and to local changes of speed due to throttling or sharp changes in size of the pipes, and also due to fluid viscosity.

“The pressure peaks that arise from entrapment of the fluid between the top and the bottom of the tooth are a serious problem for involute gear pumps. Actually, there is a rotation phase when the fluid is no longer between the housing and the profile of the teeth. In this situation — for example, at the pump inlet — it causes a noise similar to cavitation.” He said that during discharge, the fluid is rapidly compressed, creating a spike in pressure that generates noise, vibration, and mechanical stress.

The continuous contact of helical teeth in the Continuum pump, Martini offered, overcomes these problems. As with conventional gear pumps, fluid flow is perpendicular to the gear shafts. However, the gear teeth are not perpendicular. Instead they are cut at a helical angle. This helical design creates a single point of contact between mating teeth. Martini said this causes a gradual transmission of fluid movement, which reduces pulsation and any noise associated with it.

The Continuum pump is suited to both industrial and mobile hydraulic systems. Martini added, “They are widely used in the marine industry, where low noise on board large yachts is required.” The pump is offered in displacements from 4 to 4400 cc/rev.

For more information, visit www.settima.it or contact ALA Industries, Valparaiso, Ind., at (877) 419-8536 or visit www.alaindustrieslimited.com.