2026 Forecast: Opportunity Markets for Hydraulics and Pneumatics

What you'll learn:

- Challenges still facing the fluid power industry and its customer markets.

- Which industrial sectors are expected to see growth in 2026.

- How the fluid power industry can benefit from the forecasted growth in these sectors.

The fluid power industry and its various customer segments experienced challenging market conditions in 2024, and 2025 has so far not proved to be much better.

High interest rates and inventory levels, uncertainty about the global economy and tariffs are some of the top reasons cited for weaker demand in the fluid power industry and many of the customer markets it serves. While 2025 started on a more positive note for some sectors, such as metalworking and other industrial machinery applications, ongoing inflation and uncertainty related to tariffs has kept demand low for many sectors.

Heading into 2026, projections presented by various economists during the National Fluid Power Association’s (NFPA) Industry & Economic Outlook Conference (IEOC) were mixed — some noted there are signs of recovery showing in a few markets, including fluid power, while others see recovery coming later in 2026 or even 2027.

Jim Meil of ACT Research probably put it best when he said 2026 may be better but there will be a wide variance in conditions and outcomes.

That said, presenters at the IEOC also noted several markets expected to grow in 2026 which will provide opportunities for the fluid power industry in the coming year.

Future Growth in Industrial Markets will Benefit Fluid Power

Despite 2026 forecasts being a bit of a mixed bag at the moment for many of the fluid power industry’s major customer markets such as construction equipment and agricultural machinery, there are a number of other sectors in which hydraulics and pneumatics are utilized that are anticipated to fare better in the coming years.

Aerospace

According to Scott Hazelton of S&P Global Market Intelligence, the aerospace industry is currently one of the good news areas in the economy. During his IEOC presentation, he said U.S. aerospace equipment production is up in 2025, and is expected to be strong this year as well as in 2026.

He noted that nondefense orders have so far seen the highest increase in 2025 compared to defense orders. But the latter could see increased order activity in the coming year as global defense spending increases (learn more on this below).

Factors benefiting this market include Boeing workers no longer being on strike and the company having a large backlog with deliveries spread over time which Hazelton said should help spending in this sector.

Increasing cargo and passenger demand is also expected to aid future growth for the global aerospace market per the “Global Fleet And MRO Market Forecast” from consulting firm Oliver Wyman.

Aerospace is a top customer market for the hydraulics and pneumatics industry as these fluid power technologies are used both for the production of various aircraft as well as in the aircraft themselves. For instance, hydraulic hoses and other components are critical for raising and lowering landing gears on airplanes.

Therefore, the projected growth in the aerospace industry in the coming year should benefit those in the fluid power sector serving this market.

Data Centers

Hazelton also noted during his presentation that non-residential construction spending remains low other than for healthcare and data centers. Rising use of artificial intelligence (AI) and other digital technologies requiring complex computation and data processing has prompted a boom in data center construction.

In early 2025, EndeavorB2B partner site Data Center Frontier spoke with Doug Adams, President and CEO of Global Data Centers for NTT DATA who said the data center industry has been growing at a compound annual growth rate (CAGR) of about 13.5%, and further growth is anticipated in the coming years.

During his presentation on the global construction equipment market, Alastair Hayfield of Interact Analysis said the U.S. is building as many offices as it is data centers. This could help lead to increased demand for the construction equipment required to build these facilities — as well as the hydraulic, pneumatic and other components which enable these machines to function.

Hayfield noted that data centers, unlike many office buildings, have a larger physical footprint and are typically located outside of urban areas. Supporting infrastructure such as roads and water access are required as well, all of which necessitates the use of various types of construction machinery to build, particularly large earthworking machines.

Fluid power components are used in data centers as well, further aiding opportunities for the industry in this burgeoning market. Hoses, fittings, pumps and a range of other fluid conveyance related componentry are an important part of the liquid cooling systems utilized in many data centers.

Cooling systems are a necessary part of every data center, helping to prevent overheating of the chips housed in them which are used for all of the data processing that takes place at these facilities. As construction of data centers continues to grow so too will the need for the fluid power components used within them.

Defense

Nico Palesch from Oxford Economics said during his IEOC presentation that defense spending will be a big growth driver over the next few years, particularly in Europe. He noted that NATO (North Atlantic Treaty Organization) and several European countries have announced increased spending on defense in the coming years.

While S&P’s Hazelton said it is uncertain where the defense spending will be targeted, Palesch expects much of it will be on equipment as countries look to upgrade their older military vehicles, airplanes and other technology. He said the increased defense spending is likely to trickle into other sectors such as aerospace — and thus could help the projected growth for that industry in the coming years — precision and optical instruments, shipbuilding, metal products and others.

Hydraulics and pneumatics companies which either directly serve the defense industry or other related sectors are thus likely to benefit from the projected increase in spending by this industry.

Palesch anticipates much of the spending will be kept within Europe and help boost the region’s industrial economy but expects the U.S. defense industry to benefit as well.

Food Processing

The U.S. food processing industry should remain relatively healthy according to Hazelton, with growth expected in this sector over the next few years.

Coming out of the COVID-19 pandemic, the industry experienced some challenges as restaurants began to recover. But with the current economic climate which is causing uncertainty for many consumers, the food processing industry is returning to a growth trajectory.

Hazelton noted that weaker consumer confidence leads to people eating at home more, driving up retail sales for various food products. Although imported goods such as fresh produce and meats are impacted by tariffs, the majority of food processing is done domestically and therefore not subject to price increases due to tariffs.

Pneumatics in particular are commonly used by this sector to both produce and package foods, and its future growth potential should benefit those fluid power companies working in this space.

Visit Food Processing, an EndeavorB2b partner site, to learn about the latest investments food production companies are making in their businesses.

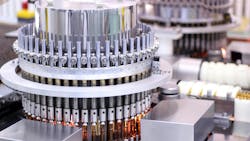

Pharmaceuticals

Another sector expected to see growth in 2026 and beyond is pharmaceuticals. Palesh said U.S. sectors that will continue to do well in the current economic climate are those already doing well and which have an established production footprint in the region such as pharmaceuticals.

Hazelton said U.S. pharmaceutical production will accelerate and shipments were already up 8% in the first half of 2025. While the industry is dealing with tariffs on imported ingredients and equipment, he said a number of companies have also announced investments in domestic production.

If these investments come to fruition, they will aid the projected growth for the sector as well as the industries which serve it like fluid power.

Learn more about recent pharmaceutical production investments in the U.S. from EndeavorB2B partner site Pharma Manufacturing:

Half of Big Pharma’s pledges to invest in US manufacturing, R&D are not new: CBRE

Trump uses threat of pharma tariffs as leverage for ‘Most Favored Nation’ drug pricing

Semiconductors

Semiconductors are expected to be another opportunity area for the fluid power industry in the coming years. The CHIPS and Science Act provided funding for the building of domestic production facilities for semiconductor chips which are used in a vast number of applications today.

Stay tuned for our upcoming piece which dives into how fluid power components are utilized for semiconductor production. The piece will be featured in the September 25 edition of our monthly In Focus newsletter, so if you haven’t already, be sure to sign up for this newsletter which curates the latest content related to technologies and trends of interest to the fluid power and broader motion control industry.

Many of these facilities are starting to come online, with more expected to do so in the near future. This will benefit the fluid power industry as hydraulic and pneumatic components are utilized in many of the production processes for semiconductor chips.

Hazelton noted that if the projected increase in defense spending occurs, it could further benefit the semiconductor industry as the chips are used in numerous types of defense applications. In addition, the Trump administration is pushing for more domestic production of semiconductors; on September 4 it announced plans to tariff imports of semiconductor chips from companies not moving production to the U.S.

If this leads to more domestic production, it could lead to further growth for the semiconductor industry and thus benefit the hydraulic, pneumatic and other technology sectors supplying products to it.

While it is too soon to know what exactly is in store for the fluid power industry and broader global economy in 2026, the growth expected in these markets demonstrates that there will continue to be areas of opportunity for hydraulics and pneumatics.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: