Understanding the Transportation Hydraulic Hose Market and its Future Opportunities

Hydraulic systems play an instrumental role in the transportation sector, from maneuvering a Boeing 737 in the stratosphere to stopping a 5,000+ ton train on the railway tracks. Via pistons, valves, hoses and tubes, hydraulic systems are capable of achieving up to 100 times force amplification which helps meet the heavy-duty performance requirements of many applications in the transportation market.

While much importance is given to the pumps and valves in most discussions around hydraulic systems, often overlooked components are the hoses, which are as essential as the wires in an electrical system, because they transfer hydraulic fluid throughout these systems to enable them to perform as desired.

The transportation hydraulic hose market is forecast to grow in the coming years due to the continued importance of hydraulics in planes, trains and other transport applications which are also expected to experience rising demand. Understanding the technical details of these hoses, the key industries in which they are used and factors affecting their future market growth will help hydraulic hose companies gain better insight into the opportunities possible in the transportation sector.

A Technical Walkthrough of Hydraulic Hoses

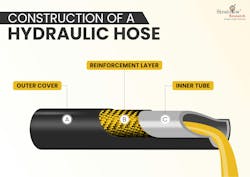

The hydraulic fluids which flow inside hoses can reach pressures as high as 10,000 psi (689 bar). But how exactly do these components withstand those pressures? It’s because hydraulic hoses consist of three distinct layers:

- an inner tube,

- a reinforcement layer, and

- an outer cover.

The inner layer directly contacts the fluid and must be chemically compatible with it. The reinforcement layer, made of materials such as steel, copper, or high-tensile-strength textiles, provides the strength needed for high-pressure applications. This reinforcement can be designed in helical, spiral, or braided patterns. The outer cover serves as a protective layer and is made of materials which are chemically resistant to harsh outer environments.

Apart from the construction of hydraulic hoses, the materials used in the manufacturing of them play an instrumental role in determining their characteristics. Mostly, two types of materials are used to make the inner tube — rubber and polytetrafluoroethylene (PTFE), each having its unique advantages and disadvantages.

Rubber hoses offer flexibility, allowing them to bend around and get to hard-to-reach areas for easy installation and affordability compared to other material types. However, rubber hoses have their shortcomings such as limited chemical and temperature resistance as well as susceptibility to degradation over time.

PTFE hoses, on the other hand, are known for their exceptional chemical resistance, wide operating temperature range and non-sticky surface that doesn’t let residue build up on it. Moreover, they are also known to be sturdy, translating to lower maintenance and a longer service life. However, not only are PTFEs more costly upfront, but also less flexible which can create installation challenges such as making precise cuts to the hoses or using specialized fittings.

The below table compares the properties of rubber vs. PTFE hydraulic hoses.

Given the balance of performance and affordability, rubber hoses prove to be a practical package for most industries and dominate the global transportation hydraulic hose market with more than 70% market share according to a report on the hydraulic hose market from Stratview Research. On the other hand, PTFE hoses occupy a smaller niche market where superior performance is critical.

Other materials such as thermoplastics, also hold a minimal share, often used in applications where neither rubber nor PTFE is the perfect fit.

Top End-Use Industries for Hydraulic Hoses in the Transportation Sector

Hoses are a critical part of the hydraulic systems widely used throughout the entire transportation sector. However, there are a few specific end-use industries where they are utilized in this market which stand out, for instance the aerospace industry.

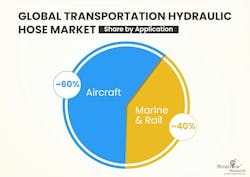

Every aircraft which has ever taken flight has relied on hydraulic hoses for the functioning of landing gears, braking mechanisms and flight control systems like ailerons, elevators, rudders, flaps, slats, spoilers, etc. According to Stratview Research's report, the aerospace industry single-handedly captures around 60% of this market.

Beyond aerospace, the marine and rail industries bring significant business for the transportation hydraulic hoses market. In marine, these hoses are utilized mostly in steering systems, winches and secondary applications like cargo handling equipment. Whereas in the rail sector, hydraulic hoses play a crucial role in enabling braking, suspension and coupling systems.

Consequently, the marine and rail industries collectively account for the remaining 40% market share of hydraulic hose use in the transportation sector per Stratview Research's report.

Future Growth Projected for the Transportation Hydraulic Hoses Market

The transportation hydraulic hose market is expected to have a healthy climb, driven by increasing demand across the aviation, maritime and rail sectors. The aerospace industry, being the single largest application for these hoses, will be a major growth driver.

Visit our State of the Industry page for my market and technology trend data for the hydraulics, pneumatics and electromechanical sectors as well as the various machinery markets they serve.

Increasing passenger and cargo demand is leading to rising demand for global aircraft fleets. According to the Global Fleet And MRO Market Forecast 2025-2035 from consulting firm Oliver Wyman, the global commercial aircraft fleet is expected to grow to 29,000+ units by the end of 2025, 32,000+ by 2030 and 38,000+ by 2035.

Similarly, the growth in maritime transport is expected to act as another important driver for the transportation hydraulic hose market. Interestingly, more than 80% of the global trade volume is transported over water, making it the hero of international trade. The United Nations Conference on Trade and Development (UNCTAD) projects a 2.4% annual growth in maritime trade through 2029, attributed to rising trade and commerce worldwide.

Furthermore, with governments worldwide investing in infrastructure projects that include high-speed rail networks and freight corridors, the demand for hydraulic hoses in the railway sector is also certain to rise.

The expansion of the aerospace, marine and rail industries will not only create demand for hydraulic hoses at the OEM level but also an increased recurring need for replacement, given the wear and tear of these components over time. Consequently, the expected growth in these sectors will unequivocally drive growth in the global transportation hydraulic hose market.

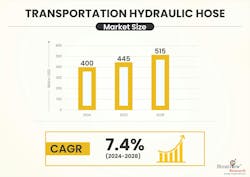

According to Stratview Research's report, the transportation hydraulic hose market, valued at ~U.S. $400 million in 2024, is expected to reach ~U.S. $435 million in 2025. Moreover, it is forecasted to grow with an impressive compound annual growth rate (CAGR) of 7.4% and reach a value of ~U.S. $515 million by 2028.

In conclusion, hydraulic hoses remain an indispensable component in powering the transportation sector, quietly ensuring the smooth operation of everything from aircraft to trains, offering a positive market outlook for this critical component in the coming years.

This article was written and contributed by Vyapak Tiwari, Associate Business Analyst at Stratview Research.

About the Author

Vyapak Tiwari

Associate Business Analyst, Stratview Research

Vyapak Tiwari, Associate Business Analyst at Stratview Research, is a seasoned professional with extensive experience in the mobility and composites domains. He has contributed to numerous articles, market briefings, and thought leadership reports, offering insightful perspectives. His expertise and in-depth knowledge have been recognized and published in various renowned platforms across the world.

Leaders relevant to this article: