New Design Opportunities for Hydraulics

Hydraulic components and systems remain an important motion technology in many machines, particularly heavy-duty mobile equipment. The transition to electrified and connected vehicles is bringing new design opportunities to hydraulics, enabling energy savings and improved control, among other benefits.

In this Q&A with Power & Motion, Tim Bankhead, Application Engineering Manager, North America at HydraForce/Rexroth, a Bosch Company, offers his thoughts on the current technology and market trends impacting the hydraulics industry.

*Editor's Note: Questions and responses have been edited for clarity.

Power & Motion (P&M): What trends or market factors do you feel had the largest impacts on hydraulic component and system designs in 2023? Please explain what those trends are and how specifically they impacted the design of hydraulics.

Tim Bankhead (TB): There's no doubt the trend toward hybrid and electric vehicles and equipment is having an impact on hydraulic components, however, the best minds in fluid power are finding ways to create more compact, powerful, energy-saving and sustainable solutions to address the application of hydraulics regardless of the power technology driving those machines.

In applications where power density and high forces are needed, hydraulics continue to offer competitive, compact and flexible solutions. High-pressure hydraulic components and systems are often smaller in size than comparable electric drives, motors and linear actuators.

P&M: How have you seen hydraulic component and system designs evolve in recent years?

TB: There is a trend of integration of digital electronic technologies – hydraulic controls with onboard electronics and integrated sensing (i.e. EDG, Innercept, EHBV from HydraForce). The integration of sensors is a critical path to adding value to the market with digitally connected hydraulics.

Energy savings is a perennial concern and Compact Hydraulics has been developing energy-efficient products that employ gravity lowering, flow sharing and fuel-savings (i.e. TS90-SG34, HSPEC, HTD torque dividers, EHBV digital boom lowering/hose burst valve from HydraForce).

There's a trend toward multi-function products, for example, proportional or directional controls with built-in compensation (i.e. EDG from CH and HSPEC from HydraForce).

READ MORE: Increased Demand for Electronic Controls Driving Hydraulic System Designs

P&M: What are some of the key features or performance attributes your company is working to include with its hydraulic components and systems, or for which customers are asking?

TB: [Customers are looking for the following:]

- Integrated sensing – [as demonstrated in the HydraForce] Innercept Digital Proportional Control and EHBV Digital Boom Control products.

- Safety – [such as in the] EHBV Digital Boom Control with hose burst protection.

- Energy-savings – [demonstrated in the] G3 valves, including TS90-G34 and EHPR.

- Sustainability – materials that lower environmental impact while providing the same or increased performance. Autonomous and Remote operation – [such as HydraForce's] ERAU Remote Access Unit, 5-way proportional valves for control of hydraulic functions on autonomous vehicles.

P&M: How much, if at all, are you seeing electronic alternatives taking the place of hydraulic components or systems? Can you offer some examples, and how you possibly see this trend progressing?

TB: Propel and rotary work functions are certainly progressing faster toward electronic solutions. Linear work functions are on a much slower track as the challenges with power density and size limit their adoption.

All-electric solutions still remain expensive and electric machines are struggling to perform a full day's work on a single charge in off-highway equipment. Hydraulics continue to offer strong advantages in most off-highway applications and blends well on hybrid systems.

P&M: Are you seeing a greater integration of electronics with hydraulics? If so, what are some examples you can share and the benefits of doing so?

TB: Yes, integration of electronics is accelerating. Some examples from our product line are:

- Use of electronic valve drivers and LVDT (linear variable differential transformer) sensors with five-way proportional cartridge valves, as demonstrated with our Innercept Digital Proportional Control.

- Use of electronic valve drivers and pressure sensors to detect and control unexpected boom lowering, as demonstrated with our EHBV digital boom control.

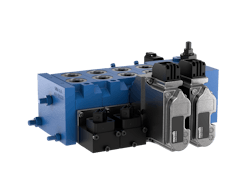

- Modular directional control valves with onboard electronics and integrated pilot functions, for precise control of higher flow hydraulic functions, as demonstrated with the EDG directional control units.

- Use of accelerometers and fluid condition, pressure, and temperature sensors added to custom manifolds and integrated hydraulic circuits (HICs).

Efficiency and digitization continue to drive the trend to adding sensors. We challenge our application engineers to re-imagine hydraulic systems when you add just one sensor to the traditional system solutions.

READ MORE: Understanding Digitalization and its Use in Fluid Power

P&M: Do you foresee any new trends or market factors impacting hydraulic designs in the coming year or years? If so, what are those and what impact will they have?

TB: The trend of localization is opening opportunities in the design cycle and allowing creativity to develop systems and solutions that meet local market performance and feature expectations.

P&M: Are there any economic/market factors you are concerned could negatively impact the hydraulics industry in the coming year?

TB: The general economy is in a dynamic situation with slowing, flat and some slight increases with conditions dependent on markets and regions. However, engineering activities are on the increase as resources that had been refocused on supply chain disruption are now focused on the next generation of machines.

P&M: How do you see the hydraulics market in general performing in 2024?

TB: Depending on the source, compared to 2023, the hydraulics market in 2024 will either be flat compared [to 2023] or slightly down due to a moderate recession expected in 2024.

Get More Market Insights!

This article is part of our 2023 State of the Industry coverage which reviews the market and technology trends impacting the development of hydraulic, pneumatic and electric motion systems.

Visit our State of the Industry hub for more Q&As, video interviews and industry insights.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: