How To Add Hydraulic Oil - Without The Dirt

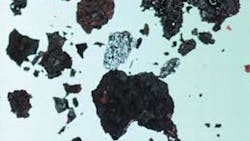

Hydraulic fluid straight from the drum, has a typical cleanliness level of ISO 4406 23/21/18. A 25 GPM pump operating continuously in hydraulic oil at this cleanliness level will circulate 3,500 pounds of dirt, on an accumulative basis, to the hydraulic system's components each year!

So to add hydraulic oil, and not the dirt, always filter new oil prior to use in a hydraulic system.

This can be accomplished by pumping the oil into the hydraulic reservoir using a filter cart. OR, if a filter cart is not available, or it's not practical to use one, the oil can be pumped into the reservoir via the hydraulic system's return filter. The easiest way to do this is to install a tee in the return line and attach a quick-connector to the branch of this tee. Attach the other half of the quick-connector to the discharge hose of a drum pump.

When hydraulic oil needs to be added to the reservoir, the drum pump is coupled to the return line and the oil is pumped into the reservoir through the return filter. As well as filtering the oil, spills are avoided and the ingress of external contamination is prevented. For the majority of hydraulic systems, the benefits of carrying out this simple modification are well worth the minor cost involved.

In summary, adding unfiltered oil to a hydraulic system is a mistake. Even if it's NEW oil. And to discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get "Six Costly Mistakes Most Hydraulics Users Make... And How You Can Avoid Them!" available for FREE download here.

About the Author

Brendan Casey Blog

Author

Brendan Casey is a war-weary and battle-scarred veteran of the hydraulics industry. He's the author of The Hydraulic Troubleshooting Handbook, Insider Secrets to Hydraulics, Preventing Hydraulic Failures, The Definitive Guide to Hydraulic Troubleshooting, The Hydraulic Breakdown Prevention Blueprint and co-author of Hydraulics Made Easy and Advanced Hydraulic Control. And when he's not writing about hydraulics or teaching it, Brendan is flat-out helping consulting clients from a diverse range of industries solve their hydraulic problems. To contact him visit his company's Website:

www.HydraulicSupermarket.com

Leaders relevant to this article: