CHAPTER 18: Miscellaneous Fluid Power Items

Fluid power accessories

Miscellaneous items

Some components used in fluid power systems do not necessarily fall into any of the categories discussed in preceding chapters. These accessory items may be used for powering, modifying, monitoring, or connecting in any type circuit, as the system designer deems appropriate.

Pneumatic accessories

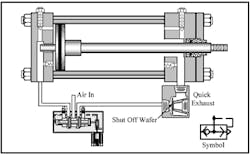

Quick exhaust valves: The speed at which an air cylinder strokes is determined by how fast compressed air enters it and how fast the air already in the cylinder exhausts to atmosphere. System pressure drives air into the cylinder and this does not pose a speed problem in most circuits. Air leaving the cylinder is different because it was at system pressure when the directional valve shifted. Although the air starts exiting quickly, it still holds the piston back. Speeding up a sluggish air-operated cylinder is best accomplished by dealing with its exhaust air. The cross-sectional view and symbol in Figure 18-1 illustrate a quick exhaust valve, which does just that.

The cylinder in Figure 18-1 delivers high impact from low force . . . stamping parts with steel dies and leaving a lasting impression. Cylinder force alone is not capable of making the desired impression -- if any impression at all. Accelerating piston speed over a few inches of travel makes the weight of the tooling act like a hammer swung through the air.

As the cylinder retracts and is held at rest, the shut-off wafer covers the exhaust port and forces air to the cylinder rod end. When the directional valve shifts to extend the cylinder, pressure drops on the left side of the shut-off wafer and trapped pressure in the cylinder forces the wafer to the left. As the shut-off wafer moves left, it closes off flow to the valve and opens a direct path to atmosphere only a short distance from the cylinder port. The rapid exhaust of air reduces backpressure on the cylinder piston, allowing high-pressure inlet air to accelerate and move the piston very quickly.

Any time slowly exhausting air is a problem, look to a quick exhaust valve to remedy the situation.

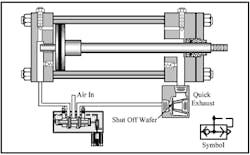

Mufflers: The air-exhaust mufflers in Figure 18-2 reduce the noise level of air-operated equipment. They are made in several different configurations out of many types of material, but the end result of all of them is the smooth discharge of air.

The sintered-bronze elements on the left are similar to filters made of the same material. They separate the flowing air into numerous paths to lessen or eliminate the loud crash of air as it leaves an actuator. The sintered-bronze element in the center has a protective metal covering and an adjustable poppet valve to control flow. It works as an inexpensive meter-out flow control when used with a 5-way directional control valve. Because a 5-way valve has two exhaust ports, these speed-control mufflers can regulate speed independently in both directions of travel. The muffler on the right is similar to those used on internal combustion engines. It may be made of plastic or aluminum. It is bulky, but causes less restriction on fast-moving actuators.

Accessory Items for pneumatics and hydraulics

The components described in the rest of this chapter are common to hydraulics or pneumatics. The main difference between them is the materials used to make them. Many pneumatic components can be made of plastic or aluminum to resist corrosion and keep cost down. These materials work well at low pressure. Most hydraulic components see high to very high pressure and need to be much more robust. Cast iron and steel are common materials for hydraulic parts due to their strength and the absence of corrosion. Aluminum is also preferred by some because of its light weight.

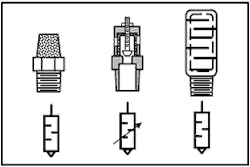

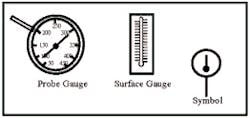

Pressure gauges: The gauges shown in Figure 18-3 come in a variety of shapes, sizes, and designs. The most common is the round model that has a moving needle to designate system pressure. The round gauge on the left and the plunger gauge measure psig, not atmospheric pressure. Because atmospheric pressure is in and around an actuator, it doesn't help or hinder performance, so it is not important when determining the amount of work being done.

The gauge marked PSIA reads atmospheric pressure instead of zero and can be used to check vacuum as well as pressure. Some of these gauges set on zero and read psi clockwise and vacuum (in inches of mercury) counter-clockwise.

Other designs include battery-operated digital-readout units. These gauges are accurate and very fast reading.

Temperature

Temperature: Knowledge of the temperature of a fluid or the atmosphere in which it works can be very important. Two styles of temperature gauge are shown in Figure 18-4. When pneumatically operated machines are in atmospheres of 32° F or less, the condensed moisture in them may freeze. When hydraulic circuits operate much above 140° F they can leak or slow down and the fluid in them starts to break down.

It is best to keep hydraulic systems between 75° and 130° F. Temperatures above 130° F can vaporize important additives and cause excessive bypass due to reduced fluid viscosity. Fluid temperatures below 75° F can result in sluggish performance.

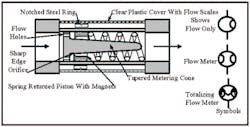

Flow meters: The cross-sectional view in Figure 18-5 shows a typical inline flow meter that indicates flow in cubic feet per minute (cfm), gallons per minute (gpm), or liters per minute (lpm). This style of meter is made of aluminum or non-magnetic stainless steel to allow the magnet-powered notched steel ring to function.

Fluid entering from the left passes through flow holes and against a spring-returned piston fitted with magnets. This piston wraps around a tapered metering cone and has a sharp-edged orifice in contact with it. The only way for fluid to get through is to push the spring-returned piston with magnets to the right. When the piston moves far enough up the tapered metering cone to allow the present rate of fluid to pass, it stops and holds. The magnets in the piston draw the notched steel ring along and the notch reads the flow amount on the clear-plastic cover with flow scales.

This type flow meter is not completely accurate but gives a clear enough indication of flow to meet most troubleshooting needs. Other designs are more accurate but less tolerant of the harsh interaction of a high flow system.

The upper symbol on the right in Figure 18-5 is for a device that only shows whether flow is taking place in the line or not. The middle symbol represents the cross-sectioned device. It indicates both the presence of flow and the flow rate. The lower symbol represents a device that shows the flow rate and keeps a running total of the amount that has passed through it.

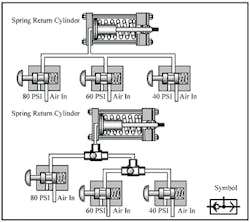

Shuttle valves: The circuits in Figure 18-6 illustrate one reason for using shuttle valves. The spring-return cylinder in the upper circuit must be controlled from three locations. This circuit uses pipe tees to interconnect the three normally closed, palm-button-operated, 3-way directional control valves with the cylinder. The only problem is this circuit will not work. When any of the 3-way valves are actuated, input air can flow directly to atmosphere through the other 3-way valves, bypassing the cylinder.

The lower circuit uses shuttle valves in place of the pipe tees. Air from any of the 3-way directional control valves can only go to the cylinder. The floating ball in the shuttle valve blocks air to the other directional control valves. Exhausting air can go to atmosphere through the valve it entered, go out the opposite valve, or exhaust through both valves. If each 3-way directional control valve has a different pressure at its inlet (as indicated), the cylinder always gets the highest pressure of the valves actuated. The ball in the shuttle valve always moves away from the highest inlet pressure.

Other circuits use shuttle valves to send more than one pilot signal to a directional control valve, read feedback signals from more than one source, or send signals from multiple actuators to a load-sensing pump. Any time multiple inputs are necessary, a shuttle valve will separate them, allow for return flow, and pass the highest input pressure. (Check valves can serve two of these functions but will not allow back flow.)

Rotary Unions

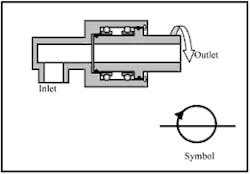

Rotary unions: Some applications require fluid to flow into or out of rotating parts of a machine. The rotation may be continuous or only part of a turn; the application may have one or many flow paths. Many manufacturers make rotary unions that do this for fluids at pressures as high as 5000 psi, with as many as 20 flow paths. . (Some rotary unions pass electricity as well as fluids if required.) The cross-sectional view in Figure 18-7 is a simplified drawing of a single-path rotary union. The symbol is a circle on a flow line; in this case, the energy triangle indicates hydraulic fluid. Multiple flow paths are shown by multiple lines of whatever type the flow is. (Some rotary unions pass electricity as well as fluids if required.)

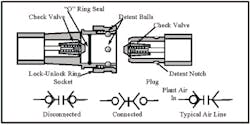

Quick disconnects: When all or any part of a pneumatic or hydraulic circuit must be removed or changed frequently, a fast way to do so is with quick-disconnect couplings. Quick disconnects usually require a worker to connect and disconnect them manually. However, there are some styles that break away when pulled by mechanical force. Other types only stay connected while held in place by an external force.

The cross-sectional view in Figure 18-8 illustrates the socket-and-plug pair that make up a typical quick disconnect. Sliding the lock-unlock ring to the left allows the detent balls to move out of the way so the plug can be inserted. Inserting the plug all the way into the socket stops leakage as it passes the O-ring seal, opens both check valves, and allows the detent balls to lock in the detent notch to hold the connection together. Sliding the lock-unlock ring to the left again releases the plug as the detent balls lose their backing. The three symbols in the figure show quick disconnects disconnected with dual check valves, connected with dual check valves, and disconnected in a typical air line configuration.

It may be necessary to install oversized quick disconnects because their construction can cause high backpressure. Always check pressure drop in the manufacturer's catalog to assure proper flow capabilities. There are designs that have full flow porting in air and low-pressure hydraulic styles.

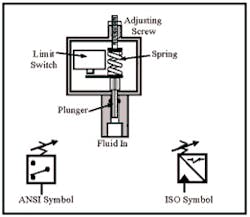

Pressure switches: Some fluid power circuits require electrical control signals when pressure reaches specific levels - such as the pressure buildup when a part is clamped or a certain weight is met - or if overpressure may cause damage or is a safety hazard. (Sequence valves -- discussed in Chapter 14 -- can cycle from a pressure buildup, but will not produce a signal to an electrical control circuit when a pressure requirement is satisfied.)

The cross-sectional view and symbols in Fig 18-9 show electrical pressure switches that are set to monitor maximum or minimum pressure and then send a signal to the electric control circuit. (Another electrical output device that reads pressure and sends a signal is a pressure transducer. Pressure transducers are more responsive and have better repeatability, but require additional electronics to read their input.)

The depicted pressure switch includes a plunger that reacts to system pressure by moving. An adjusting screw sets spring pressures against the plunger and allows different settings. When system pressure is high enough to push the plunger upward against spring tension, the plunger closes a limit switch to signal that the set pressure has been reached. When pressure falls, the plunger drops and the limit switch opens again.

Never depend on a pressure switch to indicate actuator position when the actuator positively has to be in a certain position to prevent machine or product damage or to avoid a safety hazard.

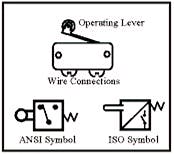

Limit Switches

Limit switches: Figure 18-10 shows an outline drawing and symbols for a limit switch. While some electrical components are shown to indicate function and location, no wiring appears on fluid power circuit diagrams.

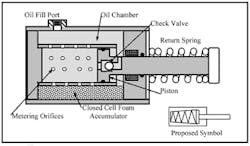

Shock absorbers: The cross-sectional view in Figure 18-11 shows an oil-filled shock absorber. (The figure also includes a proposed symbol.) When cushioned cylinders or other decelerating devices are not satisfactory or desirable, shock absorbers are one viable alternative. Shock absorbers are available in sizes from 3/8 in. or less up to models that can stop a loaded overhead crane traveling at full speed in two feet or less. Some are adjustable, some are self- adjusting. Some use metering orifices (as the figure shows), others use tapered metering cones.

Because they may absorb a lot of energy in a short period, most have the ability to transfer fluid from the last stroke to a reservoir for cooling. The same reservoir replenishes the shock absorber with cooled fluid for the next stroke.

The model depicted in Figure 18-11 uses a spring-returned piston with an integral check valve that travels through a bore with several metering orifices in it. As the piston moves through its bore, there are fewer holes for fluid to pass through. Thus, resistance to movement increases throughout the stroke. As the piston strokes, it smoothly decelerates the load at a controlled rate until it stops. Fluid forced out of the bore during the deceleration stroke is sent into an oil chamber that is partially filled with a closed-cell foam accumulator. This accumulator makes it possible for the oil chamber to accept the extra fluid and then force it back to the bore on the return stroke. An oil-fill port allows replenishment of any lost fluid.

Most shock absorber manufacturers offer formulas in their catalogs and/or computer programs to size their products for specific applications.

Hose-break valves: In pneumatic systems, there usually is more air available than is required, so if a hose ruptures or is disconnected suddenly, air will flow profusely and the loose end of the hose can whip about dangerously. A hose-break valve set for a flow greater than working flow will close automatically when flow tries to increase above its capacity. Air hose-break valves never shut off completely so when the line is reconnected, the small bleed bypass fills the repaired section and the hose-break valve opens for use.

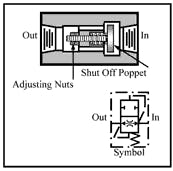

The drawing and symbol in Figure 18-12 represent a typical hose-break valve. Air flows into the right-hand port at a rate up to a certain cfm setting. The distance between the shut-off poppet and its seat determines the maximum flow rate before the shut-off poppet closes and stops flow. Reverse flow is never blocked, but is restricted to cause a pressure drop. When pressure at the right-hand port drops or when pressure at the left-hand port rises, the shut-off poppet opens to pass flow.