Pneumatic Brakes Rival Hydraulics

This file type includes high-resolution graphics and schematics when applicable.

One of the most fundamental reasons why designers choose hydraulics or pneumatics over electromechanical power transmission is power density. Both forms of fluid power can transmit higher force and velocity from a comparable actuator that is much smaller and lighter than anything offered by electromechanical technology. And because heat generation limits duty cycles of electric motors, fluid power solutions (especially pneumatics) generally can operate continuously at high cycle rates.

Hydraulics is usually considered the ultimate in high power density. That’s because fluid pressures typically measured in thousands of psi transmit extremely high force and torque from actuators only a fraction the size of their electromechanical counterparts. Pneumatic actuators, on the other hand, usually operate at much lower pressures—generally 100 psi or less.

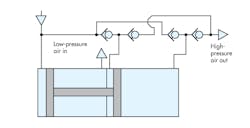

But this doesn’t have to be the case. A circuit requiring a small volume of high-pressure air is well-served by an intensifier—often called a booster. Air boosters take advantage of the area differential of two different-sized pistons to compress air to a higher pressure.

In ideal terms, the combination of pressure and volume of a gas remains constant if temperature also remains constant, widely known as Boyle’s law:

P1 × V2 = P1 × V2

where:

P1 is incoming pressure of the air,

V1 is incoming volume of the air,

P2 is outgoing pressure of the air, and

V2 is outgoing volume of the air.

Because volume and pressure are inversely proportional in this case (at least ideally), boosting the pressure of a volume of compressed air decreases its volume. Also, because no mechanical device is 100% efficient, the volume of outgoing air will be less than the ideal value derived from Boyle’s law.

Pressure Booster Is the Driving Force

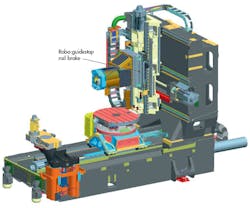

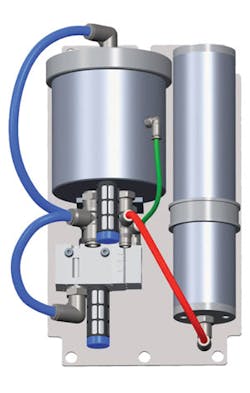

By integrating a pressure booster in with its compact safety brake, Mayr GmbH & Co., Mauerstetten, Germany, produced a spring-applied, pneumatically released brake with the high power density normally associated with hydraulics. Called the Roba-guidestop profiled rail brake, the device fulfills the ever-increasing safety requirements placed on machine builders.

Mayr also offers spring-applied, hydraulically released brakes, so if a machine has an existing hydraulic system, it can tap into that. If not, designers can specify the Roba-guidestop as a convenient and cost-effective solution for applications that have access to shop air.

Roba-guidestop safety brakes clamp onto standard profiled rails and provide backlash-free operation. Compressed air at 20 to 30 bar (290 to 435 psig) opens the clamp to release the brake. When compressed air is exhausted—either intentionally or from a machine malfunction—a powerful spring closes the clamp to securely grip the rail.

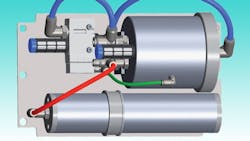

To achieve a high-enough pressure to overcome spring force, a compact pressure booster is used in combination with the brake to multiply inlet air pressure about five times the 4 to 6 bar (58 to 87 psig) typically found in pneumatic systems—with no need for an auxiliary power source. The design selectively increases pressure directly upstream of the brake, which minimizes the length of the required high-pressure lines.

The Roba-guidestop safety brake comes in five different sizes—each size in both a standard design and compact, short design—covering a range of holding forces from 1 to 34 kN (225 to 7,640 lb). Each brake is compatible with different profiles and sizes of conventional linear guide rails.

As with its hydraulic brake design, Mayr’s pneumatic Roba-guidestop safety brake remains structurally rigid and mounts directly to the load, allowing it to apply braking force directly to the linear guide rail. Safety is a clear advantage to this technique, especially concerning gravity-loaded axes, which otherwise presents potential risk to personnel.

The Roba-guidestop eliminates the need for drive elements between the motor and the moving mass—such as spindles, spindle nuts, shaft couplings, and gearboxes— that could potentially sacrifice safety. Machines using Roba-guidestop safety brakes, therefore, provide significantly higher rigidity than systems using rotary brakes integrated into servomotors.

The backlash-free clamping of the Roba-guidestop directly onto the profile rail provides additional advantages. The high rigidity of the rail axis maximizes process accuracy to improve machine performance, especially in applications involving heavy loading. The rigid structure also transmits less vibration, which improves surface quality of work pieces.

If an axis is stationary when machining or other operations occur, the brake can absorb the load. Instead of relying on drive motors to hold the axis steady, the closed brake absorbs axial forces and consumes no energy. This eliminates control movements and reduces vibration transmitted to the ball-screw spindle, which extends service life and maintenance intervals of the drive components.

Mayr power transmission products are available in the U.S. at Mayr Corp., Waldwick, N. J., and from distributors across the country. For more information, call (201) 445-7210, or visit www.mayrcorp.com.