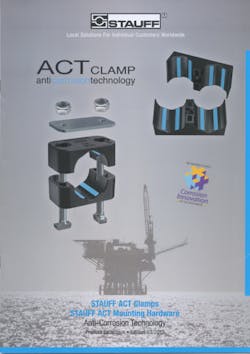

Anticorrosive clamps

ACT Clamps are used to install pipework where corrosion resistance is crucial, as in offshore oil and gas exploration. The clamps are constructed of flame-retardant PPV0 plastic and feature integrated anticorrosion elastomer strips that prevent the accumulation of seawater between clamp body and pipe. Drainage channels aid in the dispersal of seawater. The brochure also covers ACT mounting hardware that is made of stainless-steel V4A with enhanced corrosion resistance. The hardware is suited to temperatures from –25 to 90°C (–13 to 194°F), has high UV stability of the clamp body material, and is resistant to seawater, rain, and oil. The clamps cover commonly used metric and imperial pipe diameters from 6 to 25,4 mm (¼ to 1 in.).

Stauff Corp., (201) 444-7800