Think First, Then Troubleshoot — Chapter 9: Relief Valves

Chapter 9: Relief valves

The unsung hero of many hydraulic systems often is the relief valve. The hydraulic relief valve’s contribution is extremely important because it limits the amount of power a system can generate. The relief valve thus helps to ensure that intended system pressure will not e exceeded. This pressure limitation helps avoid damage to other hydraulic components and the machinery or injury to workers.

The relief valve function helps establish the fact that hydraulics is a convenient and efficient method for transmitting power. Mechanical and electrical power transmission systems cannot match the simplicity and low cost of the relief valve.

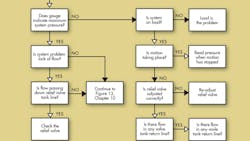

Referring to Figure 12, the troubleshooter should install a pressure gauge at the upstream test point – if one is not already in place – to determine the maximum pressure at which the system will operate as controlled by the relief valve. Many makes of relief valves provide a port in the valve to connect a gauge.

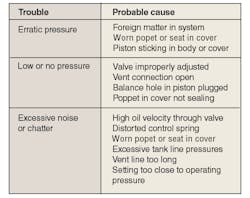

Figure 12 provides simple and quick means for determining if the problem is with the relief valve or elsewhere in the system. If the troubleshooter determines that the problem is in fact with the relief valve, Figure 12 suggests possible causes of typical troubles.

About the Author

Alan Hitchcox Blog

Editor in Chief

Alan joined Hydraulics & Pneumatics in 1987 with experience as a technical magazine editor and in industrial sales. He graduated with a BS in engineering technology from Franklin University and has also worked as a mechanic and service coordinator. He has taken technical courses in fluid power and electronic and digital control at the Milwaukee School of Engineering and the University of Wisconsin and has served on numerous industry committees.

Leaders relevant to this article: