Case Drain Monitoring: Part of a Healthy Recipe to reduce Downtime

Typical maintenance recommendations such as systematic pressure checking or performance degradation monitoring leave much to be desired. A common scenario involves using a pump in a degraded condition until it fails — a costly and inefficient practice. Using a pump under these conditions wastes energy, introduces the potential for more costly repair, and could put other system components in a compromised state.

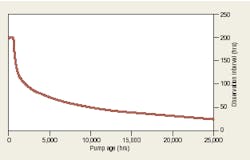

Operating the pump for an extended period of time in a degraded condition causes excessive performance or pressure load capability degradation. By this point, excessive wear particles may have made their way through the system.

Typically 50% of hydraulic system component failures can be attributed to mechanical wear due in part to particulate contamination. This justifies the need for adequate and well-maintained filtration and urges us to explore ways to curtail the damaging effects of excessive particulate contamination.

Rebuilding the pump and restoring the system after excessive degradation and pump failure requires that critical tolerances in the pump be brought back into specification. Ideally, the system should be flushed clean of excessive particulate debris. Efforts to restore a system in this condition are certainly more costly and intensive than simply repairing a pump prior to excessive degradation or fragment failure.

Maintenance indicators

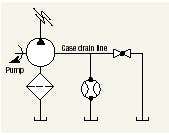

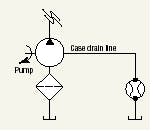

Pump case drain flow monitoring allows evaluation of pump status without interrupting operation. As wear degrades a pump's critical tolerances, excess fluid leaks past internal seals and moving parts into the case, robbing the pump of efficiency. This increase in leakage to the case can be monitored in many pump styles. When the case drain flow exceeds a percentage of total pump output, the need for maintenance or complete pump rebuild becomes evident. (However, case drain flows in continuous recirculation hydrostatic configurations are not indicative of true pump case leakage.)

The use of pump case drain monitoring as a maintenance indicator for hydraulic pumps presents some challenges:

Ease of use — Maintenance indicators and other diagnostic devices must offer simple and expedient test procedures that do not interrupt the production of the system. Case drain monitors offer system operators and maintenance people a simple and nonobtrusive means of observing abrupt changes in pump case drain flow.

Effectiveness — An effective maintenance indicator must provide a means of indicating the need for maintenance with splitsecond certainty. When applied correctly, case drain monitors provide definitive measurement of the need for pump maintenance as it relates to abrupt changes in case to reservoir flow.

Reliability — Case drain monitors applied as maintenance indicators or diagnostic tools are designed for years of service when installed and maintained in accordance with manufacturer's instructions.

Installation constraints — The monitoring of pump case drain flow must be performed in accordance with manufacturer's specific guidelines. One of the installation precautions should involve checking the pump manufacturer's guideline for maximum case drain line pressure. This pressure must exceed the restriction imposed by the the flow monitor.

Case drain monitors

The case drain monitor provides maintenance a means of taking notice of relatively abrupt changes in a pump's operating characteristics. By noting the baseline flow from the pump case to the reservoir under typical operating conditions, you can log changes in pump case drain flow at periodic intervals. Applied correctly, case drain monitors offer a way to quickly and conveniently monitor the pump for significant changes in performance or operating efficiency.

Indication of abrupt changes in pump case drain flow as a diagnostic measure must be considered within a consistent range of operating conditions. These operating conditions provide a basis from which a pump case drain flow reading can be taken and comparatively interpreted. Consistency should be noted regarding temperature and system load when taking readings, as both will affect actual pump case leakage. For best results, monitoring case drain flows must be considered as part of a systematic maintenance process.

Aside from pump case drain flow monitoring, other elements of the systematic approach include system age (on-hours), flow under load testing, and system fluid testing. Pump case drain flow monitoring benefits and compliments these elements.

For example, as system age approaches the expected life of the pump, more frequent checking of the case drain flow could be called for. On the other hand, as case drain flow increases, more frequent checking of the system fluid may be warranted. The strategy of increasing the observation frequency to address the increasing rate of degradation is advisable.

Through strategic monitoring of the case drain flow and other systematic measures, personnel can address pump maintenance requirements prior any excessive degradation or fragment failure modes. Unfortunately, plants that depend on the reliability and continuous operation of pumps in various systems are most drastically affected by extended periods of system downtime. Under such circumstances, it is crucial to anticipate and plan for failures. Excessive costs or down-time periods are simply not acceptable. Adoption of pump case drain to reservoir flow monitoring as part of a predictive maintenance program warrants consideration. This is not to say that non-mission critical plants will fail to benefit from the monitoring of case drain flows as part of a strategic maintenance and diagnostic program. Plants that depend on reliable operation of the equipment in question are generally less able to maintain production capacity in the event of unexpected system downtime.

Proper meter selection

Choosing pump case to reservoir flow monitors for different pump designs or configurations is left to the discretion of the user. Familiarity with the pump and its operation in the system is important. You must consider the pump's mode of operation as well as any other device that could use the main pump case as a path to divert flow back to the reservoir. The case drain monitor is designed for straightforward use as long as application and installation details are addressed.

First, determine the flow rate of the application. This effort typically involves calculating 10% of the total output of the pump and choosing the closest flow range. Sizing the monitor correctly makes it easy to take readings at the flow rates required, and the pressure loss due to the meter will be minimized. In many cases the reading that results will not correspond directly to an offered flow range, so rounding up to the nearest range is recommended.

If the case drain monitor presents a restriction in the case-to-reservoir drain line, exceeding that dictated by manufacturer recommendations, an installation in tandem with a low-cost bypass valve could be considered. This type of configuration would allow the person taking the measurement to temporarily divert flow through the meter and then straight back to the reservoir.

Rob Copsey is a mechanical engineer at Lake Monitors Inc., Milwaukee. Contact him at [email protected] or visit www.lakemonitors.com. He acknowledges the contributions of Rory McLaren, of the Fluid Power Training Institute, and Applied Industrial Technologies in preparation of this discussion.