LDT lets RoGator adapt to the task at hand

When it comes to versatility, machines don’t get much better than the RoGator, manufactured by AGCO Corp., Duluth, Ga., at it’s facility in Jackson, Minn. Three sizes of RoGators all come with a 4-wheel hydrostatic drive system and closed-loop electrohydraulic steering that provides 2-wheel steer, all-wheel steer, auto steer (which provides 2-wheel steer until the front wheels pivot 6° or more, at which time 4-wheel steer automatically kicks in), and crab steer.

RoGators also use electrohydraulics for variable track width. This feature allows the operator to set track width anywhere from 120 to 154 in., so the RoGator can be used for spraying different crops, which typically are planted at different furrow widths to maximize yield based on the crop.

All three sizes of RoGators are driven by a pair of load-sensing axial-piston pumps, each driving a pair of axial-piston motors — one for each wheel. Each hydraulic motor drives a planetary gear wheel drive, a combination that transmits high-torque power to the wheels smoothly and efficiently.

Electrohydraulic versatility

Randy Kremmin, engineering manager at AGCO, explained that the RoGator’s versatile steering is accomplished using an electronic control system that senses orientation of the front and rear wheels through rotational sensors mounted at the left-front and left-rear wheels. The rear wheels are normally kept in the straight-ahead position for conventional front-wheel steering. If the operator activates all-wheel steer, the rear wheels will mirror angular position of the front wheels. This provides a tighter turning radius than with 2-wheel steering, and it also causes the rear wheels to drive over the same path as the front wheels, thereby minimizing soil disturbance.

If the operator activates auto steer, the rear wheels remain in the straight-ahead position unless the front wheels have pivoted 6° left or right of center. When this occurs, the electronic control senses that the left front wheel has reached its angular threshold, at which time it commands the rear wheels to match the angular position of the front wheels, but in the opposite direction.

Kremmin added that auto steer is especially useful because operators generally do not want all-wheel steer when they’re working a row of crops. All-wheel steer essentially doubles the turning action of the vehicle, so the driver would tend to wander left and right instead of keeping the machine driving straight ahead.

At the end of a row, however, the operator would want all-wheel steer for a tighter turning radius and to reduce damage to the ground. Auto steer kicks in as soon as the operator turns the wheels sharply left or right. Without auto steer, the driver would have to engage all-wheel steer at the end of every row, then disengage it before engaging on the next row.

Kremmin said the flexibility of the electronic steering system made it easy to incorporate the crab steering through simple programming. With crab steering, the control reads the orientation of the front wheels and sends a signal to the rear wheel steering to match the position of the front wheels. He explained that operators normally do not need crab steering in the field, but crab steering adds maneuverability for moving around obstacles in other areas of a property.

More electrohydraulics

Another RoGator innovation that uses electrohydraulics is track width control. When the RoGator will be used on a crop with a narrower or wider furrow width than was used previously, the operator activates a 3-way switch that causes cylinders with stroke position feedback to extend or retract.

Each of the vehicle’s four wheel mounts has a hydraulic cylinder that extends or retracts to increase or decrease track width, respectively. Track width adjustment is done with the vehicle in motion to prevent binding along the ground as the wheel moves axially. Adjusting the track of both the front and rear wheels is done inside the cab.

In a standard machine, the operator activates the track adjustment and either exits the vehicle or has a second person measure the distance between wheels. Kremmin said the RoGator eliminates the need for manually measuring the track by incorporating a linear displacement transducer (LDT) for each track cylinder.

AGCO designers wanted to incorporate LDTs for automated track width adjustment prior to 2010; however, the cost of incorporating a magnetostrictive sensor was more than the market support. Magnetostrictive LDTs have gained widespread use for position feedback of hydraulic cylinders, especially in industrial applications. Here, high-production machines require positioning accuracy to within thousandths of an inch, which justifies the cost of a magnetostrictive LDT.

However, Mark Hoffman, of Rota Engineering North America, Dallas, pointed out that because mobile equipment has a human operator, position feedback from cylinders generally only needs to be within hundredths of an inch. “Put simply, magnetostrictive LDTs are overkill for most mobile equipment applications, explained Hoffman. “An LDT with slightly less precision, but substantially lower cost, enables designers to provide cylinder position feedback more often — not just for the most critical applications that justify high cost. Hall-effect sensors generally have resolution of 0.012 to 0.020 in., which is more than sufficient for mobile hydraulic applications.”

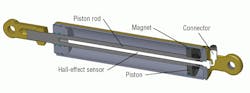

As with magnetostrictive LDTs, Rota Engineering’s Hall-effect LDTs use a piston-mounted magnet to detect stroke position of the hydraulic cylinder. However, unlike magnetostrictive LDTs, Hall-effect technology can sense magnet position through the cylinder’s steel wall. Therefore, the Hall-effect LDT can be mounted outside the cylinder (eliminating the need to gun drill the cylinder’s piston rod), or inside the cylinder — similar to how magnetostrictive LDTs typically are mounted. The small size of Rota Engineering’s sensor does not change the pin-to-pin dimensions of the cylinder. Therefore, it does not require changing the geometry of the machine (in this case, turning radius).

After investigating multiple options for cylinder position feedback, AGCO designers chose Rota Engineering’s Hall-effect LDT for their smart track width control. Next, they had to choose between an internally or externally mounted sensor. Because the environment includes fertilizers, pesticides, and other agricultural chemicals, it was decided that internal mounting would protect the sensor from potentially hostile environments but still allow fast removal in the field conditions.

Hall-effect LDTs

Rota Engineering’s sensors use a microprocessor that transmits and receives signals from Hall-effect chips mounted to a printed circuit board. The circuit board is contained within a stainless steel or aluminum housing, depending on application requirements. A piston-mounted magnet causes a voltage drop when it passes over the Hall-effect chip. The microprocessor calculates the position of the Hall-effect chip and correlates the voltage drop to a proportional voltage, current, PWM, SSI or CAN output.

“An additional benefit of the Hall-effect technology,” added Hoffman, “is small size. In most instances, the pin-to-pin dimension of a cylinder need not be increased to accommodate a Hall-effect LDT. Also, the surface-mount technology tolerates high levels of vibration to MIL-STD-202G.”

For more information on AGCO Corp.’s self propelled sprayers, visit www.rogator.com.

Click here to see a promotional video summarizing AGCO's RoGator, or click here to see a detailed tour of a new RoGator by Paul Haefner, RoGator marketing specialist.

For information on Rota Engineering’s Hall-effect sensors, call Mark Hoffman at (972) 359-1041, email [email protected], or visit www.rota-eng.com.