Fabbri's Optimal line of crushers features a gentle pressing action — powered by pneumatics — suitable for all types of grapes, fresh or fermented. Stainless-steel construction eliminates the danger of contamination from grease, metal chips, or other substances. A range of press sizes can handle juice volumes from 132 to 9,000 gal.

Getting it done

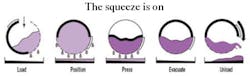

About half of the cylindrical press chamber’s surface is perforated with laser-cut slots that allow the juice to pass through easily and exit. The other half of the cylinder surface is unbroken, except for doors to load the grapes and unload the press cake at the end of a cycle. A flexible food-grade synthetic membrane separates the two halves of the press chamber. An electric motor rotates the cylinder on its longitudinal axis to position it for loading and unloading, to tumble the grapes, and to break up the press cake for easier removal.

After grapes are loaded into the press, compressed air slowly inflates the membrane so it presses the grapes against the perforated surface. After the pressing cycle is complete, a solenoid valve vents the membrane to atmosphere while a vacuum pump evacuates the remaining air — pulling the membrane back against the inside surface of the drum.

Fabbri delivers the Optimal presses with one or two high-quality, industrial air compressors and a vacuum pump. (A two-way valve permits connecting an external air supply.) Users can choose manual operation or automatic cycling managed by a PLC for more consistency. Typical cycles gradually build pressure to a maximum of 2 bar and hold it between 2 and 20 minutes.

Harv Tomlinson, of Oklahoma Export Co., the US agent for Fabbri, provided information for this article.

About the Author

Richard Schneider

Contributing Editor

Contributing Editor, has been affiliated with Hydraulics & Pneumatics for more than 30 years and served as chief editor from 1987 through 2000. He received a BSME from Cornell University and also completed additional courses at the Milwaukee School of Engineering. His diverse background in industry includes ten years with a fluid power distributor and a variety of other professional positions. He has also been active with the National Fluid Power Association and Fluid Power Society.

Leaders relevant to this article: