Valve Adds Safety to Pneumatic Circuits

This file type includes high resolution graphics and schematics when applicable.

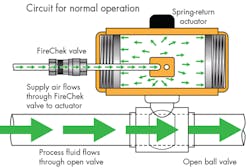

Many piping systems for hazardous or flammable fluids use pneumatically operated, quarter-turn actuators for the safety of keeping electricity out of the area. Assured Automation, Clark, N.J., offers its FireChek shutoff valve to add another level of safety to these applications. When mounted in the pneumatic supply line, the FM Global-approved FireChek valve quickly responds to heat in the event of a fire and automatically exhausts pressure in the actuator’s pilot line to close the supply line.

An element made of shape-memory alloy inside the FireChek undergoes a martensitic phase transformation when it is heated above 135°, 150°, or 165° F. This change releases stored strain energy to produce the necessary force to shift the valve; no other power source is involved. The element is 100% reliable because the shape memory effect is intrinsic to the alloy. Shape-memory alloys have performed successfully for decades in military, industrial, and consumer product applications.

For testing, the FireChek valve can be actuated with a hot-air gun, then, after a cool-down period, reset manually for continued protection. Because the FireChek valve can be tested and reset, it has an advantage over emergency isolation valves that rely on fusible links or plastic burn-through tubing. Furthermore, the FireChek valve responds to heat, not flame, so it offers better protection than plastic tubing burn-through.

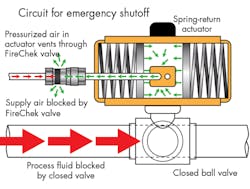

When the FireChek valve senses excessive heat from a nearby fire, it closes the air-supply line preventing the air from feeding the fire and simultaneously vents the spring-return actuator so it can return to its on, off, or throttling fail-safe position. The FireChek valve reacts within 25 sec. at a temperature rise rate of 30 Ì F/min. and can exhaust 1-l of air in less than 1 sec. at 125 psi (8.62 bar).

The FireChek valve is available in three different configurations. The standard valve mounts directly between the pneumatic supply line and spring-return valve actuator via two ¼-in. connections. A quick-exhaust version has a larger exhaust port, which increases the valve’s flow coefficient from 0.56 to 3.3 for quicker response time. The FireChek Plus version combines the FireChek valve with a SIL Class III pilot valve, either with or without a solenoid operator. It comes with either a piped connection to the actuator or a NAMUR mounting interface for direct mounting of the pilot to the actuator. They are available for actuators with port sizes from ¼ to 1 in.

For more information on Assured Automation’s FireChek safety shutoff valve, call Assured Automation at (800) 899-0553 or visit http://assuredautomation.com/firechek.