Air logic continuously reciprocates cylinder

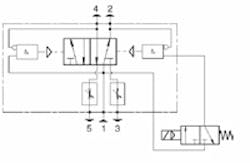

Hoerbiger-Origa Corp.'s pneumatic oscillating valve offers an economical, automatic control for a variety of applications that call for a cylinder to reciprocate continuously. This component packages a solenoid-operated 3-way valve, a 5/2-way pilot-operated power valve, and a pair of AND logic elements that act as pilots. Each AND element has one inlet connected to the power valve's supply port and the other connected to one of its outlet ports. When the solenoid valve shifts to pass supply pressure, air flows through the open outlet port of the power valve to the cylinder. When the endofstroke pressure inside the cylinder becomes high enough to shift its AND element, the power valve pilot-shifts to its other position. Flow now passes to the other outlet port and the cylinder reverses. The ANDs continue to shift the power valve automatically at each end of the cylinder's stroke. An adjustable throttle in each of the power valve's exhaust ports controls cylinder speed and stroke frequency.

By installing the solenoid-actuated valve in the supply line upstream from the reciprocating circuit, Hoerbiger-Origa allows users to initiate reciprocation with a simple electrical signal. As long as an electrical signal is maintained at the solenoid coil, the cylinder reciprocates continuously. When the electrical signal is interrupted, the cylinder completes its current cycle and then returns to its home position. The cylinder always starts from a defined starting position, so control over reciprocation is consistent.

The ¼-in. power valve has a CV of 1.3. Standard coil voltages are 12- and 24-V DC, and 110- and 220-V AC. An integral manual override-(not shown in the schematic) lets the valve be operated without an electrical signal.