Clamshell Box System Aims to Improve Air Leak Repair

What You'll Learn

- How the Clamshell Box System design enables air leaks to be repaired without requiring a full system shutdown.

- Steps for installing the clamshell box to contain leaks at the joints of air system piping.

- Benefits of using the Clamshell Box System for temporary and permanent air leak repairs.

Fixing a leak in a manufacturing facility’s air system typically requires the entire system to be shut down so repairs can be made safely. Unfortunately, this can be disruptive to an operation as downtime can be costly and prohibitive to productivity.

The Clamshell Box System, however, is engineered to provide a reliable and adaptable solution for repairing leaks in pneumatic pipe systems that eliminates the need for these system shutdowns. It diverges from traditional repair methods by employing a two-part clamshell box configuration and specialized grommets to contain leaks at pipe joints.

Using an electrofusion process, the clamshell box and grommets are fused into a single, monolithic, and hermetically sealed unit around the leak to contain it, creating a robust, in-situ (i.e., in the original place) solution that can be either permanent or temporary.

In this article, author Gregory Johnson, inventor of the Clamshell Box System, outlines key features of its design as well as its installation and removal processes to demonstrate how it can help improve upon traditional pipe repair methods.

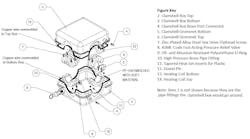

Key Design Features of the Clamshell Box System

The Clamshell Box System is engineered to provide a reliable and adaptable solution for repairing leaks in the air systems at manufacturing facilities. It functions by clamping grommets and the box around leak areas, typically at pipe joints, to contain the leaks.

The clamshell box is then securely closed using an electrofusion process. This process utilizes an embedded copper coil that is situated near the mating surfaces of the clamshell box halves which melts its two halves together, forming a fused, single part. This fusion extends to the grommets, which also melt to the box, creating a monolithic, hermetically sealed structure.

Primary components of the two-part clamshell box are fabricated from high-density polyethylene (HDPE) or a similar polypropylene composite material. This material was chosen for its structural rigidity, chemical resistance, and suitability for electrofusion.

Two ports are included on the clamshell box, similar to those on electrofusion polypropylene pipe connectors, to which an industry-standard electrofusion machine is connected. In addition, the box features an interior clip system that holds it closed together once positioned. This system ensures proper alignment of the mating surfaces and securely seats the box onto the grommets.

The system’s grommets are designed to directly interface with pneumatic piping and are also constructed from high-density polyethylene or polypropylene material to ensure material compatibility for thermal fusion with the clamshell box halves. Each grommet half incorporates a pre-installed sealing gasket on its interior radius made from a resilient elastomeric material, such as nitrile rubber or EPDM (ethylene propylene diene monomer rubber), selected for its compressibility and ability to form a fluid-tight seal against a pipe surface.

Grommet halves are secured together using standard machine screws, typically fabricated from stainless steel for corrosion resistance.

A safety valve, rated for a maximum of 200 psi, is incorporated into one of the clamshell box halves as well to prevent air pressure buildup inside the box during the electrofusion process. The valve body is typically constructed of brass or stainless steel to ensure its durability.

How to Use the Clamshell Box System

If choosing to use the Clamshell Box System to repair air system leaks, the following operational instructions will help ensure the system is used correctly and repairs are made as desired.

Step 1: Surface Preparation

Prepare the external surfaces of the pipes adjacent to the leaking joint by doing the following:

- Sanding the pipe surfaces slightly perpendicular to the flow to create a suitable texture for sealing.

- Following sanding, surfaces should be thoroughly cleaned to remove any debris or contaminants.

Step 2: Grommet Installation

An aligning tool is used to position one half of the grommets at the correct, predetermined distance from the piping joint and directly on the pipe (e.g., straight, elbow, T). This distance is critical for proper alignment with the clamshell box.

- The corresponding second half of the grommet is then screwed into the first half and around the pipe.

- When screwed together, the attached sealing gasket gets pressed against the pipe, forming a tight primary seal.

- This process is repeated for all pipes connected to the joint: two positions for a straight joint, three for a T-joint, and four for a cross joint.

Step 3: Clamshell Box Placement

Prior to final assembly, one half of the clamshell box can be used as a template to verify the correct spacing and alignment of the installed grommets. Each grommet features an exterior circular channel designed to mate with a corresponding feature inside the clamshell box. It is recommended to check alignment with one half of the box first.

- Once alignment is confirmed, the two halves of the box are taken and clipped around the joint and around the circular channel of the grommets.

- The box's integrated clip system will hold it closed. Once fully closed, the clip system cannot be unclipped, and attempting to forcibly open it will result in damage or breakage to the clips, emphasizing the need for proper initial alignment.

- At this point, the safety valve needs to be opened to prevent air pressure buildup inside the box during the fusion process. The safety valve limit is 200 psi.

Step 4: Electrofusion Process

Connect an industry-standard electrofusion machine to the clamshell box's ports to begin the electrofusion process.

- Follow the machine's instructions for pre-process or warm-up.

- The settings for the power used will be decided by the box manufacturer requirements. The machine supplies a specified voltage and current to the embedded copper coil.

- The electrical energy heats the coil, causing the surrounding polypropylene material of the box halves and the grommets to melt and fuse together, creating a hermetically sealed structure.

- Upon completion of the electrofusion cycle, disconnect the electrofusion machine.

- Allow time for the box assembly to cool down so the fused material can solidify.

Step 5: Finalization

After the cool-down period, the safety valve can be closed again. An inspection of the box can be made to ensure a complete and uniform seal has been achieved.

Process for Disassembly if Clamshell Box is Being Used Temporarily

For applications where the repair is intended to be temporary, the clamshell box assembly can be removed by following these steps:

- Re-application of Electrofusion: The electrofusion machine is reconnected to the ports of the fused clamshell box.

- Controlled Melting: A higher voltage is applied to the embedded coil, which re-melts the fused polymer along the original seam of the box halves.

- Separation: While the material is in a molten state, prying tools are used to carefully separate the two halves of the clamshell box.

- Grommet Removal: Once the box is removed, the screws on the grommets can be accessed and unfastened, allowing for their removal from the pipes.

The Advantages of Repairing Air Leaks with the Clamshell Box System

The Clamshell Box System's ability to contain leaks without requiring system shutdown is among the key benefits it offers and a significant departure from traditional static repair methods for industrial air system piping.

Advantages of using the Clamshell Box System include:

- Permanent or Temporary Solution – The box can stay permanently or be made temporary by re-applying electrofusion at a higher voltage to re-melt and pry it open, allowing for grommet unscrewing.

- Rapid Repair Process – The process is performed quickly, usually within 20 minutes, as opposed to shutting down the system and replacing joints and pipes. This helps to save time and costs for manufacturing operations.

- Code Compliance – Manufacturing operations can remain within code requirements by quickly addressing leaks.

- Enhanced Seal Integrity – Use of electrofusion enables a single, hermetically sealed part to be formed which keeps air leaks contained.

In summary, the Clamshell Box System represents a significant advancement in pneumatic pipe leak repair by prioritizing operational continuity and efficiency. Its unique dual-half configuration and electrofusion mechanism allow for an in-situ, rapid, and customizable repair that traditional methods cannot offer.

The box system can also streamline the air audit process by providing the distributors of the compressed air audit a means of quickly fixing leaks found during the audit process.

By securely containing leaks without air system shutdowns, the box system minimizes discomfort and fatigue in terms of operational burden. Additionally, it is designed to be used with any pipe material (copper, stainless, black, galvanized, aluminum etc.), enhancing the overall efficiency and compliance of manufacturing operations.

Additional technology can be added to the clamshell box as well to enable system monitoring so any potential issues can be addressed before they turn into larger issues.

This innovative design has the potential to improve productivity and reduce costs for industrial facilities of all sizes.

This article was written and contributed by Gregory Johnson, inventor of the Clamshell Box System. He can be reached via email at [email protected].

About the Author

Gregory Johnson

Inventor and Fluid Power Industry Professional

Gregory Johnson is an inventor and fluid power industry professional with over 10 years’ experience. He holds a Fluid Power Degree from Alexandria Technical College and has worked in outside sales for distributors of Sullair and Quincy compressors which offered opportunities to work with their compressed air audit teams. He has two patents for fluid power technologies he’s developed, including one pending for the Clamshell Box System and one for a hydraulic and pneumatic connector. He can be reached via email at [email protected].

Leaders relevant to this article: